Knock detection device of internal combustion engine

A technology for detection devices and internal combustion engines, which is applied to measuring devices, internal combustion piston engines, combustion engines, etc., can solve the problems of small knock judgment value and misjudgment, and achieve the effect of ensuring tracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

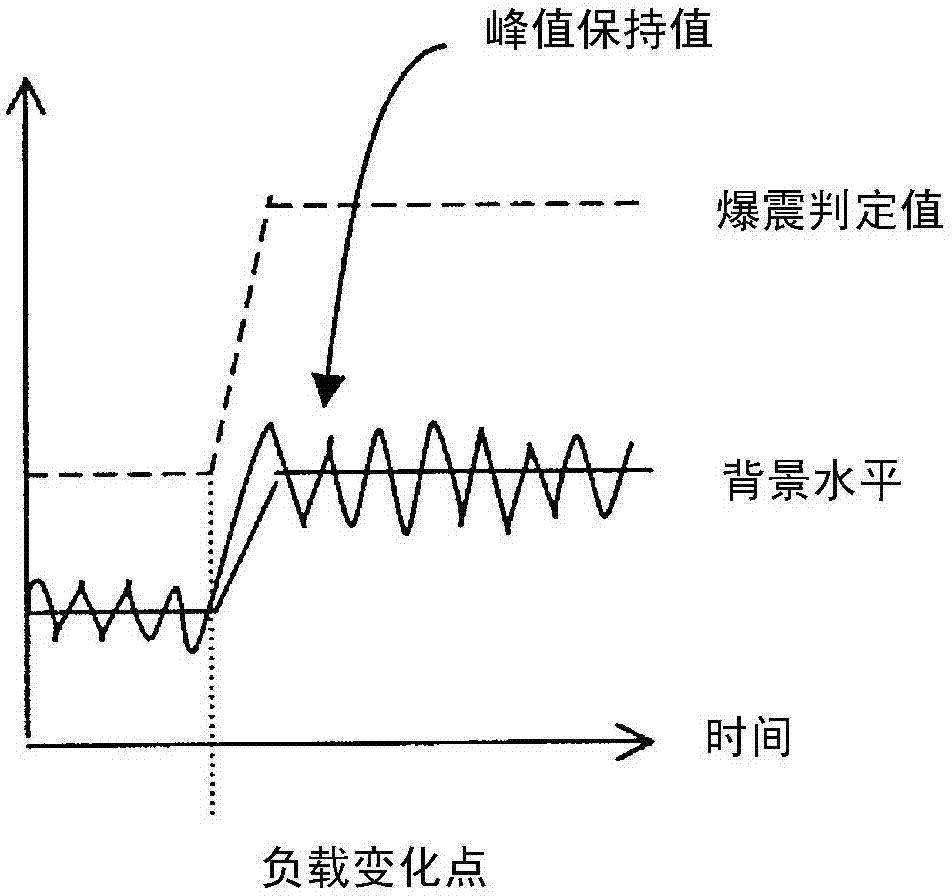

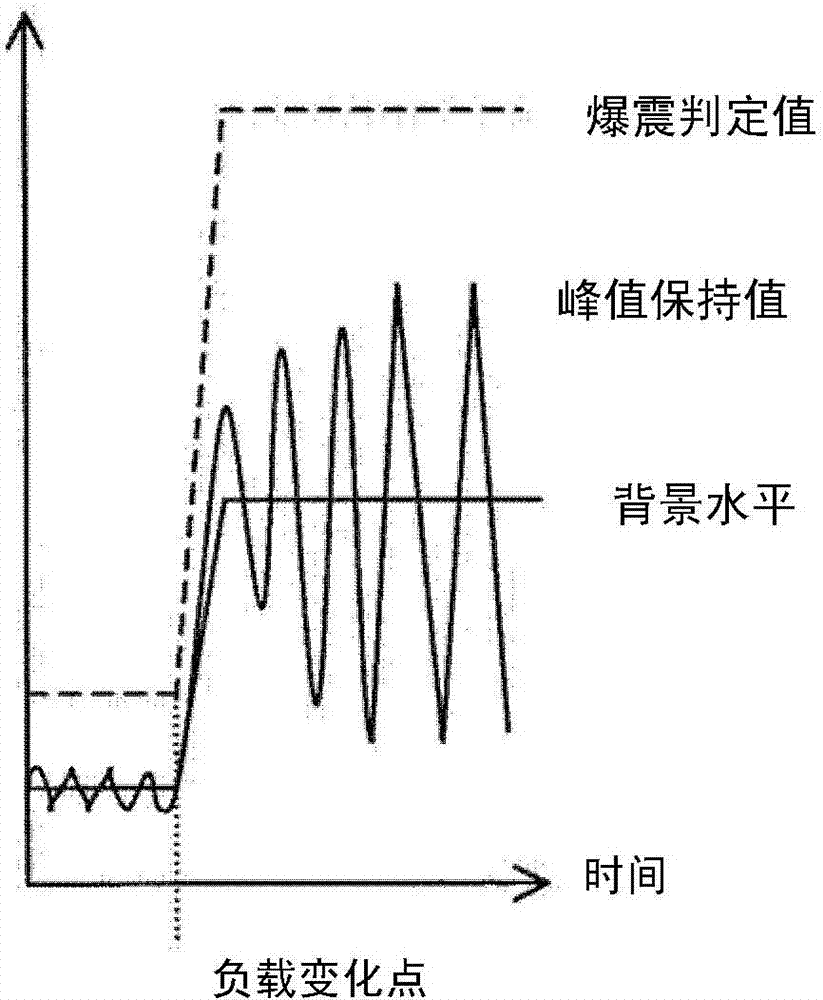

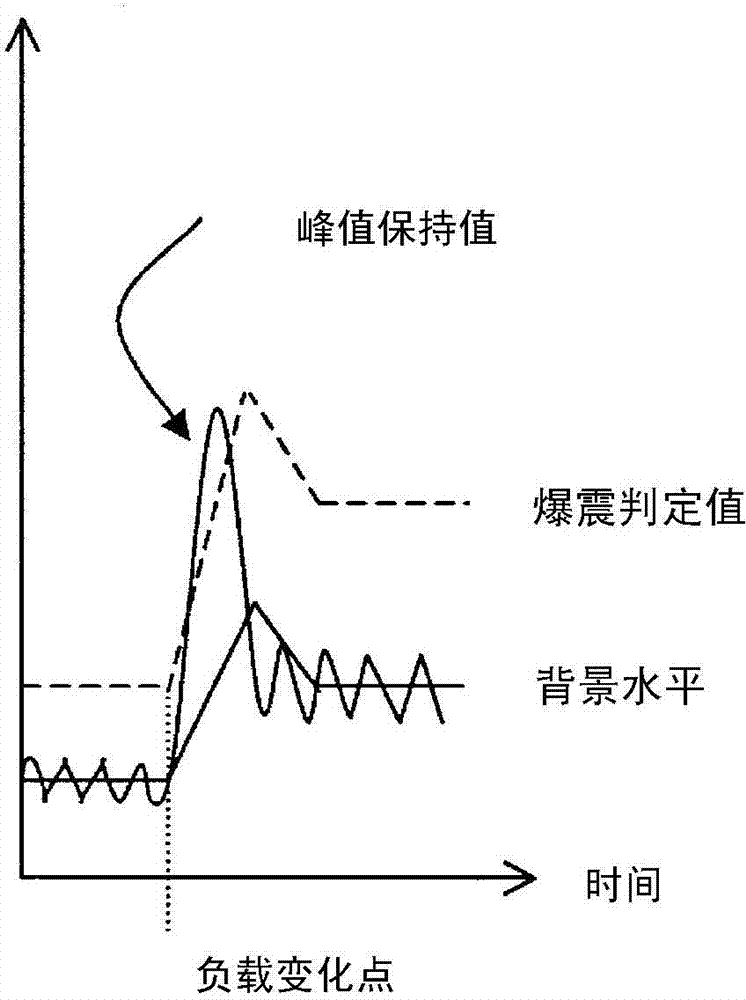

Embodiment approach 1

[0073] Hereinafter, a knock control device using the knock detection device for an internal combustion engine according to Embodiment 1 of the present invention will be described in detail with reference to the drawings. Image 6 It is a configuration diagram schematically showing an internal combustion engine including a knock control device using the knock detection device according to Embodiment 1 of the present invention. In addition, an internal combustion engine for a vehicle such as an automobile generally includes a plurality of cylinders and pistons, but Image 6 For the sake of illustration, only one cylinder and piston are shown.

[0074] exist Image 6 In the air intake system 100 of the internal combustion engine 1, an air flow sensor 2 for measuring the intake air flow rate and outputting an intake air flow signal corresponding to the measured value is provided from the upstream side, and the opening degree is electronically controlled to adjust further. The el...

Embodiment approach 2

[0120] A knock detection device for an internal combustion engine according to Embodiment 2 will be described. Embodiment 2 differs from Embodiment 1 in the calculation method of the maximum value L of the peak hold value, so this part will be described. The maximum value L of the peak hold value is defined depending on the rotational speed ne of the internal combustion engine. The setting method of L is the same as that of Embodiment 1. The data of the peak hold value under various operating states and loads of the internal combustion engine without knocking are obtained, and the maximum value is classified by the speed ne of the internal combustion engine, and is set as tabular data. This is Figure 5 The case of L, for example, such as Figure 10 Set it that way.

[0121] exist Figure 8 In the maximum value L of the peak hold value labeled 22, use the speed ne to Figure 10The interpolation is performed in the table, and the result is used as the maximum value L of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com