Model test apparatus and test method for monitoring dam saturation line

A technology of model test device and wetting line, which is applied in the direction of displaying liquid level indicator through pressure measurement, etc., can solve the problems of difficulty in determining the rationality and representativeness of analysis results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

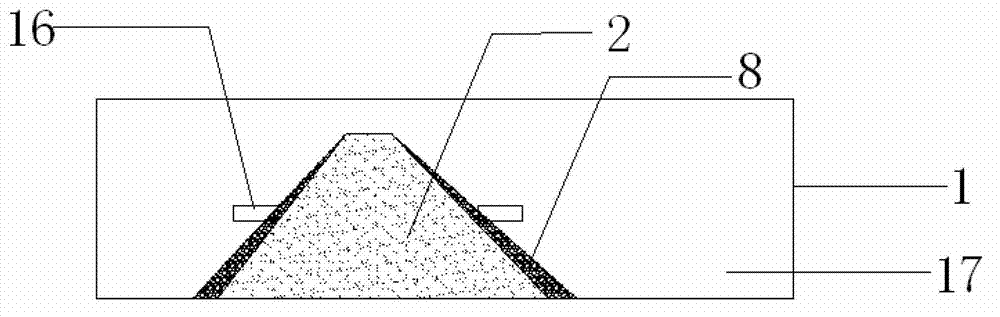

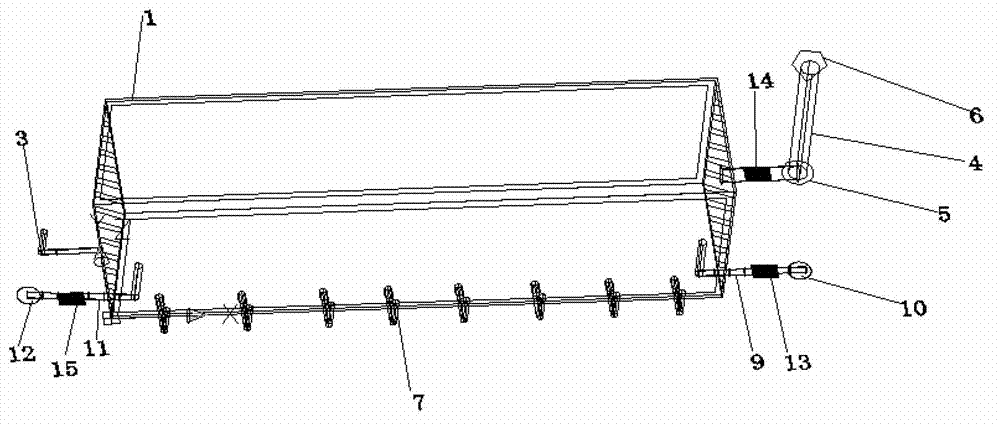

[0111] Example 1: The dam body is filled with clay materials, and the water inflow speed is 5cm / min, 10cm / min, 15cm / min.

[0112] (1) First close the drain valve and read the reading of the grating ruler. Open the water inlet valve, control the opening size of the water inlet valve, observe the reading of the water inlet flowmeter, and make the water flow into the water-facing side 17 of the dam body at a rate of 5 cm / min.

[0113] (2) While storing water, observe and record the changes in the water level of each piezometric tube and the readings of the grating ruler. According to the model scale, the observed time of the model test is 1 / 40 times of the corresponding actual time. During the decline of the water level in front of the dam, the change of the water level of the piezometric tube and the reading of the grating ruler were observed once every 2 times / 1 minute. After the water is stored to the maximum water storage height of 0.8m, close the water inlet valve. Stabil...

Embodiment 2

[0118] Example 2: The dam body is filled with clay materials, the water inlet speed is 5 cm / min, and the drainage speed is 0.25 cm / min, 0.45 cm / min, 0.65 cm / min.

[0119] (1) First close the drain valve and read the reading of the grating ruler. Open the water inlet valve, control the opening size of the water inlet valve, observe the reading of the water inlet flowmeter, make the water flow into the water side 17 of the dam body at a rate of 5cm / min, store water to the maximum water storage height of 0.8m, and close the water inlet valve. Stabilize for a period of time to fully saturate the dam body, read the readings of the grating ruler, and observe the water level of each piezometric tube until it is stable.

[0120] (2) Simulate the situation where the reservoir releases water and the water level in front of the dam drops. When the model slope reaches saturation and is in a stable state, open the drainage valve on the upstream side to release water, so that the water lev...

Embodiment 3

[0124] Example 3: The dam body is filled with clay and silt materials, the water inlet speed is 5 cm / min, and the drainage speed is 0.25 cm / min, 0.45 cm / min, and 0.65 cm / min.

[0125] (1) Fill the dam body with clay materials, close the drainage valve, and read the reading of the grating ruler. Open the water inlet valve, control the opening size of the water inlet valve, observe the reading of the water inlet flowmeter, make the water flow into the water side 17 of the dam body at a rate of 5cm / min, store water to the maximum water storage height of 0.8m, and close the water inlet valve. Stabilize for a period of time to fully saturate the dam body, read the readings of the grating ruler, and observe the water level of each piezometric tube until it is stable.

[0126] (2) Simulate the situation where the reservoir releases water and the water level in front of the dam drops. When the model slope reaches saturation and is in a stable state, open the drainage valve on the ups...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com