Blade-type sealing device

A sealing device and vane-type technology, which is applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems of brush seal failure, increased wear, and excessive wear of the free end of the brush wire, so as to reduce the seal gap and improve the seal. performance, solving uncontrollable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

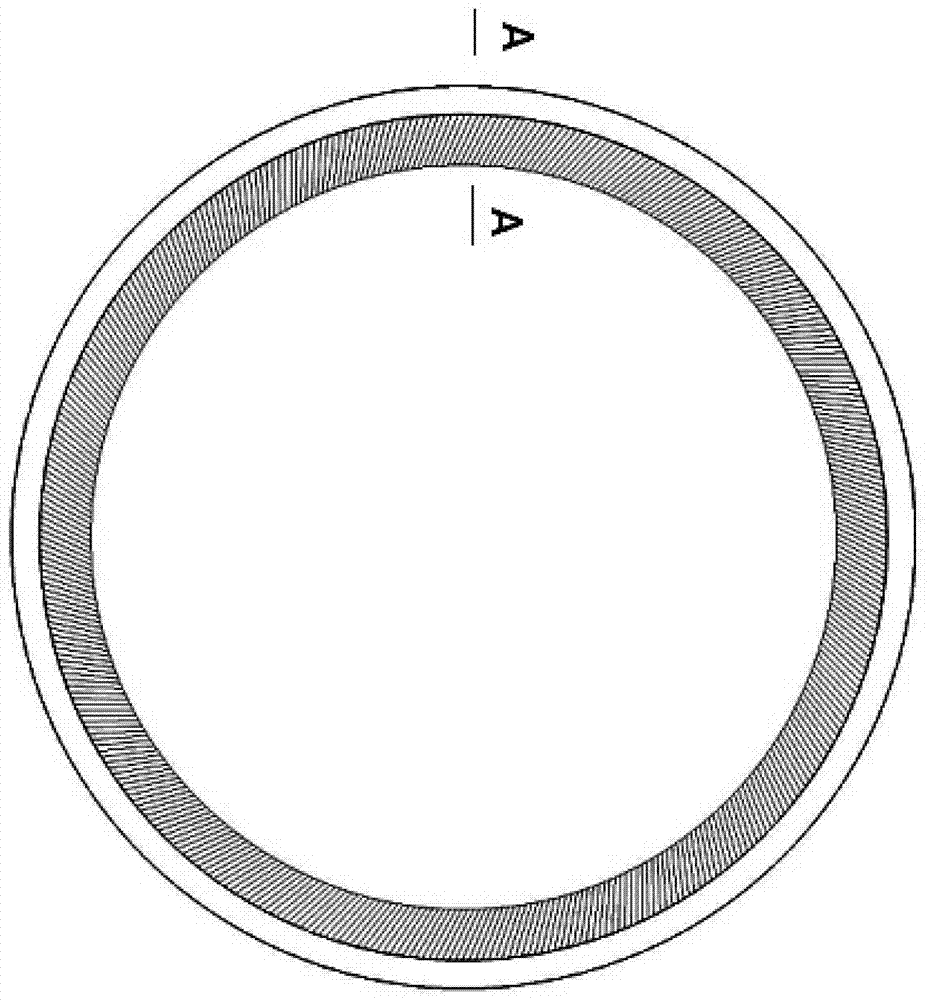

[0039] like Figure 1-3 The blade-type sealing device shown includes an upstream ring, a downstream ring and more than one blade. The blade is a rectangular sheet, one end is fixed between the upstream ring and the downstream ring, and the other end is a free end. The blade is connected to the upstream ring and the downstream ring. The rings are welded connections.

[0040] The length of the blade is 15 mm, the width is 1 mm, and the thickness is 0.1 mm.

[0041] On a plane that passes through the blade and is perpendicular to the axial direction of the rotor of the rotary machine, and along the direction of rotation of the rotor, the angle between the line connecting the blade root of the blade and the axis of the rotor of the rotary machine and the blade is 30°; the blade and the vertical The angle between the faces is 15°.

Embodiment 2

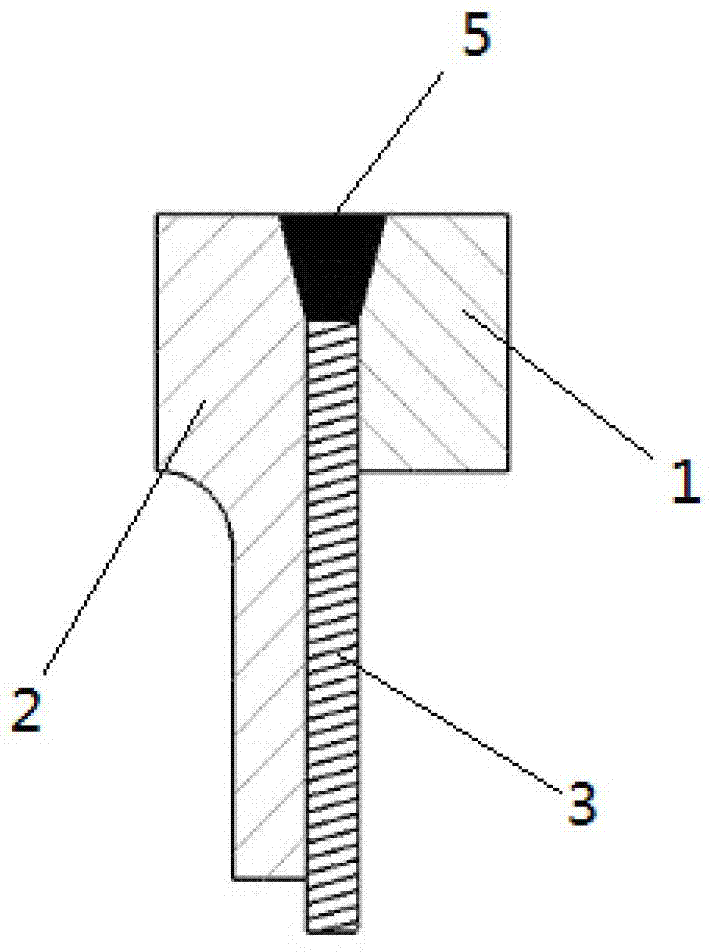

[0043] like Figure 4 The blade-type sealing device shown is basically the same as that of Embodiment 1, the difference is that several blades are made into blade modules that are easy to disassemble and replace, and are clamped between the upstream ring and the downstream ring; the blades have a length of 12 mm and a width of 1.2 mm. mm, with a thickness of 0.15mm. The blade module includes an upper splint, a lower splint and more than one blade. The blade is a rectangular sheet, one end is fixed between the upper splint and the lower splint, and the other end is a free end. The free end of the blade is high An upstream ring and a downstream ring are provided, the upstream ring is adjacent to the upper splint, and the downstream ring is adjacent to the lower splint.

[0044] On a plane that passes through the blade and is perpendicular to the axis of the rotating machinery rotor, and along the direction of rotation of the rotor, the angle between the line connecting the blade...

Embodiment 3

[0046] like Figure 5 The blade-type sealing device shown is basically the same as that of Embodiment 1, the difference is that: the inner diameter of the upstream ring is the same as that of the downstream ring, both of which are larger than the inner diameter determined by the free end of the blade; the back of the blade and the downstream ring are provided with balance Chamber; the length of the blade is 20mm, the width is 1.5mm, and the thickness is 0.2mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com