Preparation method of hollow Fe/Fe3O4@SiO2 nanostructure with adjustable wave-absorbing property

A technology with wave absorbing properties and nanostructures is applied in the field of preparation of hollow Fe/Fe3O4SiO2 nanostructures to achieve the effects of low cost and simple process operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

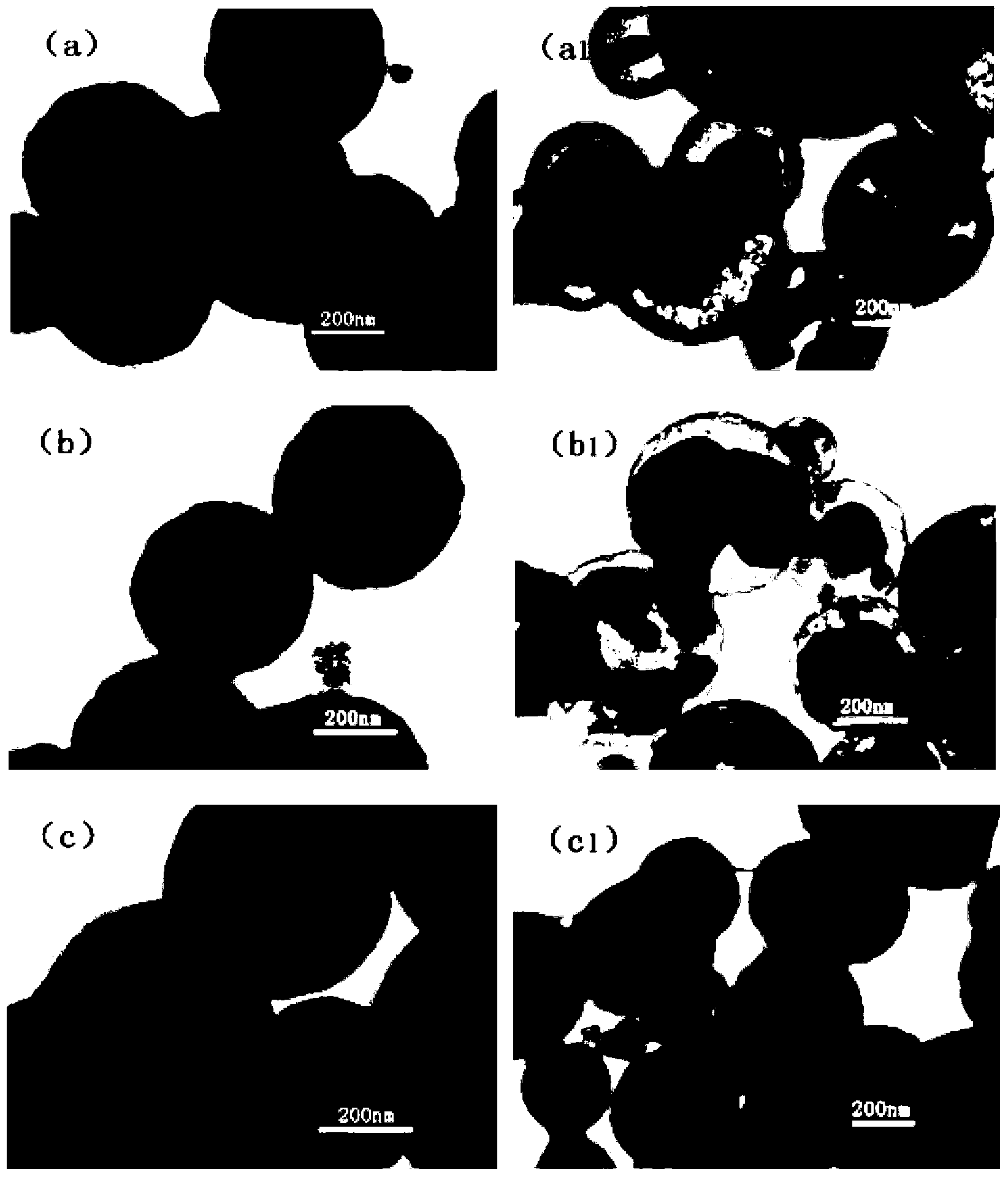

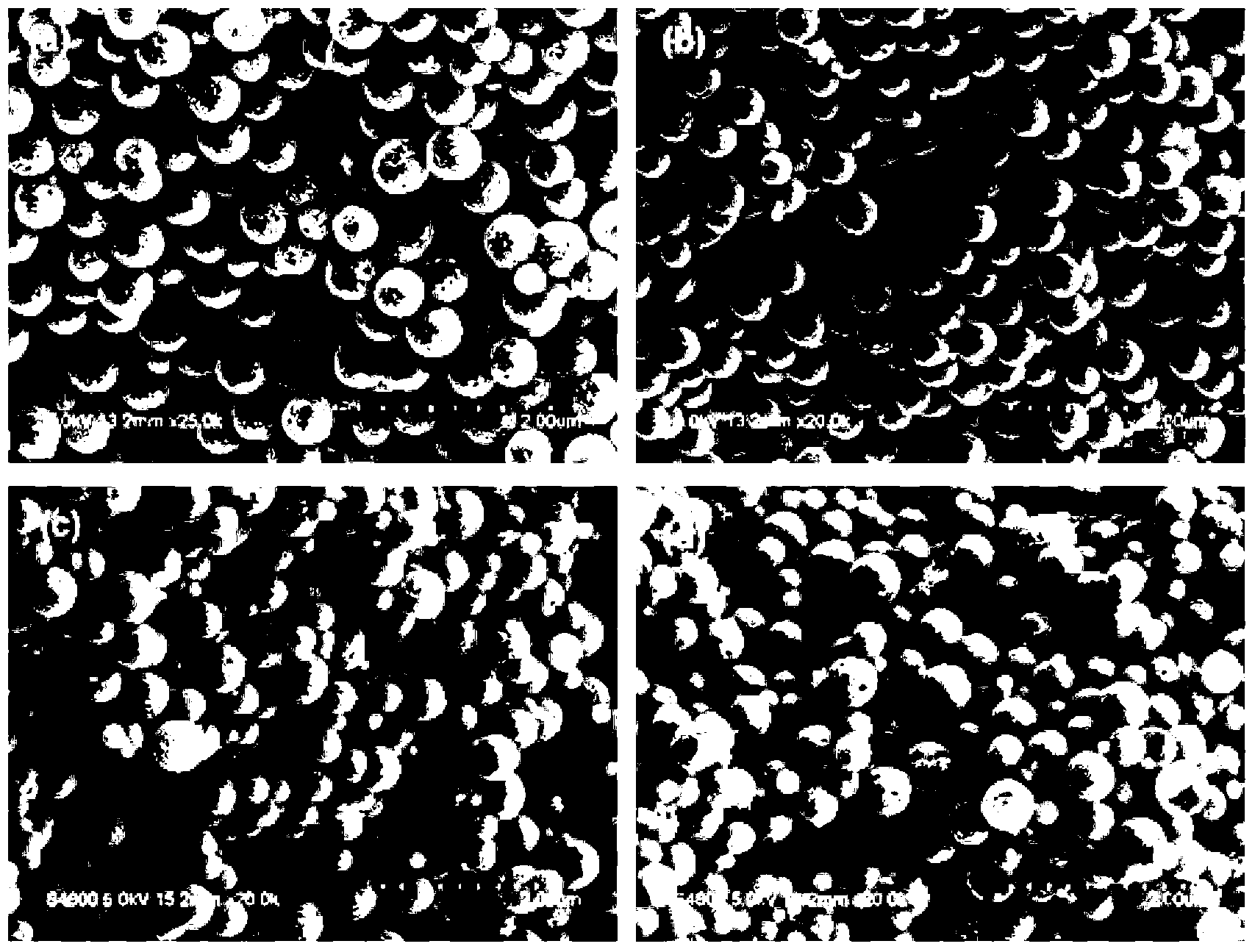

[0028] 1), hollow Fe 3 o 4 Preparation and pretreatment of nanoparticles

[0029] Ferric chloride hexahydrate as raw material, ethylene glycol as solvent and reducing agent, NH 4 Ac was used as a structure-directing agent, and a hollow Fe with a size of about 340 nm was prepared by solvothermal reaction at 200 °C for 12 h 3 o 4 nanoparticles, 0.2 g of Fe 3 o 4 Nanoparticles were sonicated in 0.1 mol / L hydrochloric acid solution for 10 min, then separated and washed;

[0030] 2), using the improved St?ber method to prepare Fe 3 o 4 SiO 2 nanocomposite particles

[0031] Fe treated with hydrochloric acid solution 3 o 4 Nanoparticles were dispersed in 100 mL of a mixed solution of absolute ethanol and water at a ratio of 4:1, the pH of the solution was adjusted to 10, and 2 mL of ethyl orthosilicate was added dropwise under mechanical stirring at room temperature. ester (TEOS), stirred for 12 h, after the reaction, washed with distilled water and dried in vacuum to ob...

Embodiment 2

[0035] 1), hollow Fe 3 o 4 Preparation and pretreatment of nanoparticles (same as Example 1)

[0036] 2), using the improved Stäber method to prepare Fe 3 o 4 SiO 2 nanocomposite particles

[0037] Fe treated with hydrochloric acid solution 3 o 4 Nanoparticles were dispersed in 100 mL of a mixed solution of absolute ethanol and water at a ratio of 4:1, the pH of the solution was adjusted to 10, and 2 mL of ethyl orthosilicate was added dropwise under mechanical stirring at room temperature. ester (TEOS), stirred for 8 h, after the reaction, washed with distilled water and dried in vacuum to obtain hollow Fe with core-shell structure 3 o 4 / SiO 2 nanocomposites;

[0038] 3) Preparation of Fe / Fe by high temperature reduction method 3 o 4 SiO 2 Nano composite material (same as embodiment 1)

Embodiment 3

[0040] 1), hollow Fe 3 o 4 Preparation and pretreatment of nanoparticles (same as Example 1)

[0041] 2), using the improved Stäber method to prepare Fe 3 o 4 SiO 2 nanocomposite particles

[0042] Fe treated with hydrochloric acid solution 3 o 4 Nanoparticles were dispersed in 100 mL of a 4:1 mixed solution of absolute ethanol and water, and the pH of the solution was adjusted to 10. At room temperature, 4 mL of ethyl orthosilicate was added dropwise under mechanical stirring. ester (TEOS), stirred for 12 h, after the reaction, washed with distilled water and dried in vacuum to obtain hollow Fe with core-shell structure 3 o 4 / SiO 2 nanocomposites;

[0043] 3) Preparation of Fe / Fe by high temperature reduction method 3 o 4 SiO 2 Nano composite material (same as embodiment 1)

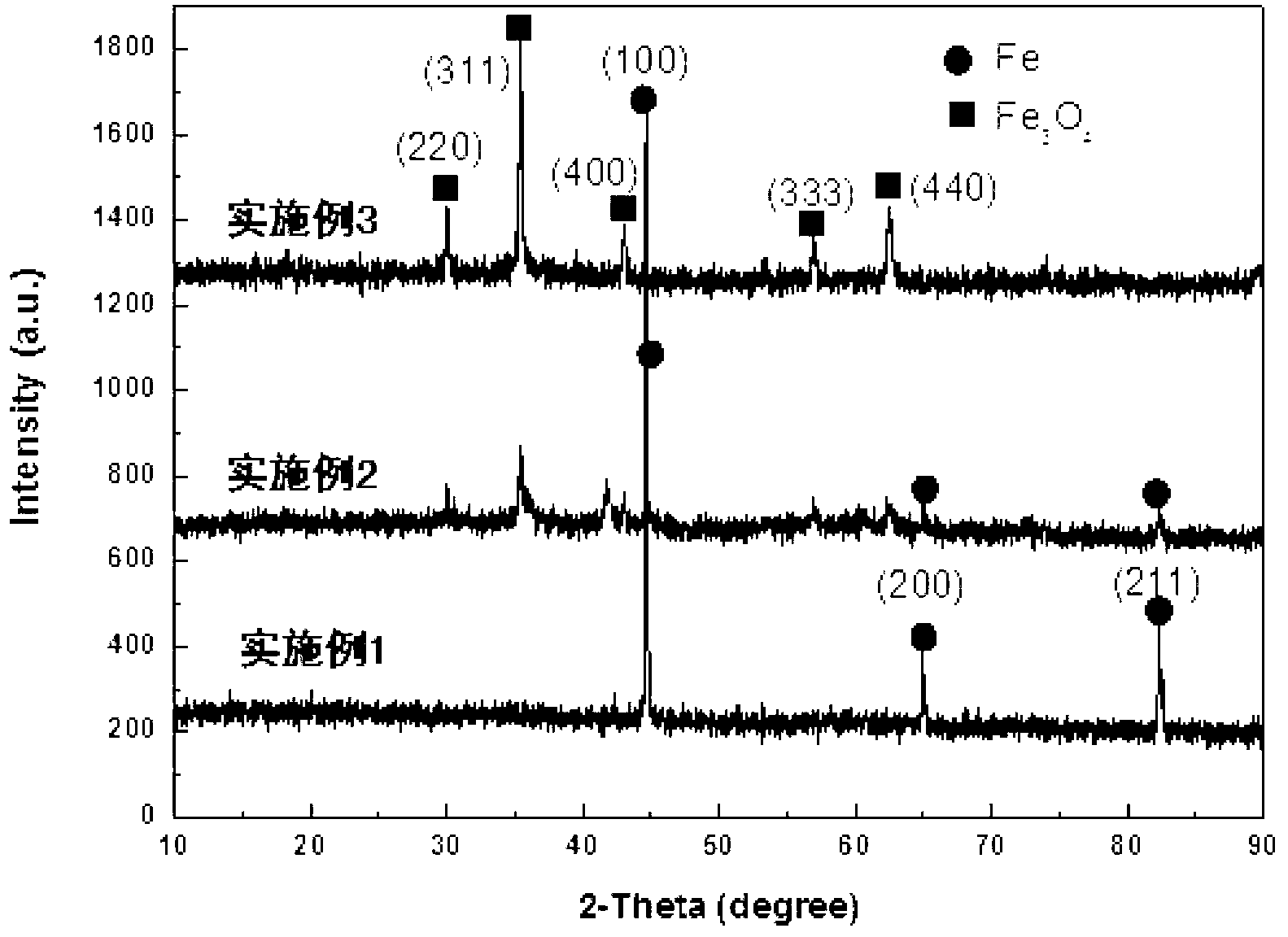

[0044] Hollow Fe / Fe of the present invention 3 o 4 SiO 2 Reflection loss of nanostructured tunable material at low and high frequencies, SiO 2 The thickness of the shell can be control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Return loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com