Tower rotary dobby automatic stacking machine

A fully automatic stacking machine and tower rotary technology, which is applied in the stacking of objects, unstacking of objects, transportation and packaging, etc., which can solve the problem of long linear movement distance of brick transfer, uncompact structure of the unit, large space occupation, etc. problems, to achieve the effect of reducing the daily maintenance workload, good motion stability, and reducing the occupied area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

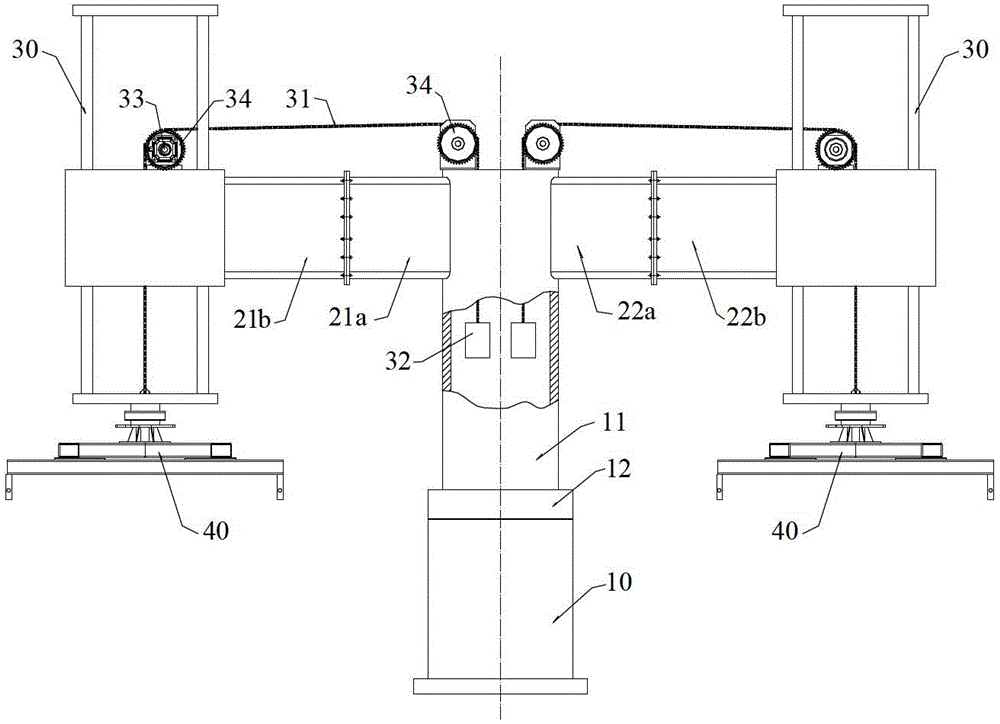

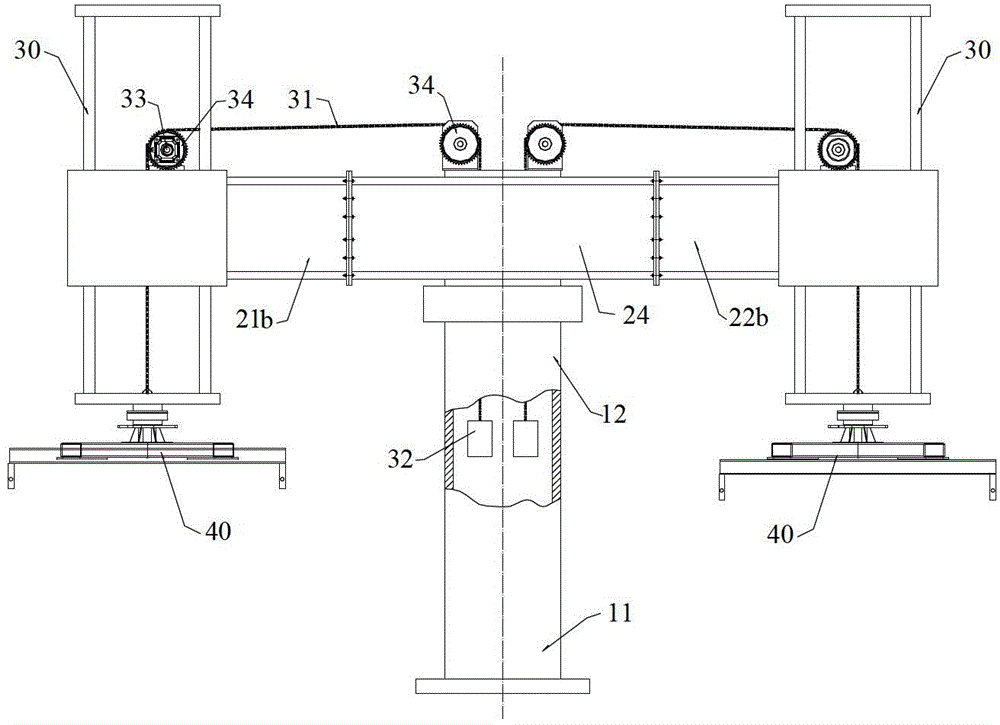

[0011] refer to figure 1 and figure 2 , the tower-rotary multi-arm fully automatic blanking machine of the present invention is characterized in that: it includes a rotatable column device, at least one swing arm device and a corresponding lifting device, and a chuck system 40; each swing arm device is fixedly connected to a The top of the rotating column device is arranged symmetrically along the circumferential direction; lifting devices are provided at both ends of each swing arm device, and a chuck system 40 is fixedly installed on each lifting device.

[0012] The present invention realizes the rapid transfer of the chuck system between the positions of the marshalling machine and the kiln car through the rotation of the swivel arm device, and at the two ends of the swivel arm device, the action of clamping the billet from the marshalling machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com