Improved bag making machine

A bag making machine and control box technology, applied in container manufacturing machinery, rigid/semi-rigid container manufacturing, box making operations, etc., can solve problems such as easy opening, wrinkled deformation of packaging bags, and unguaranteed heat sealing time and temperature, etc. , to achieve the effect of not easy to open and reduce wrinkle deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

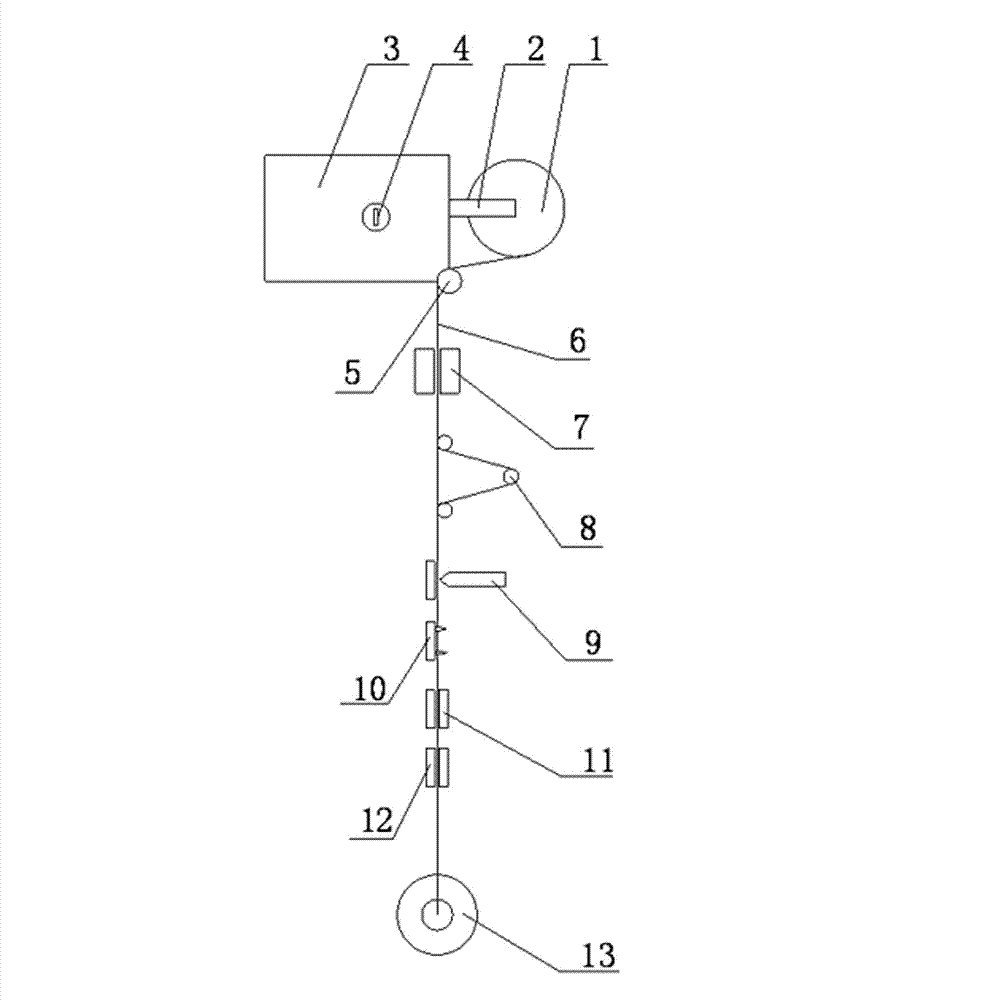

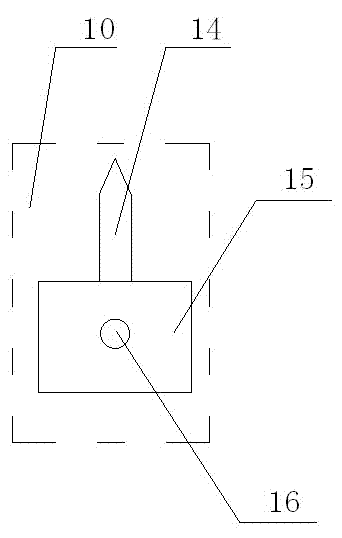

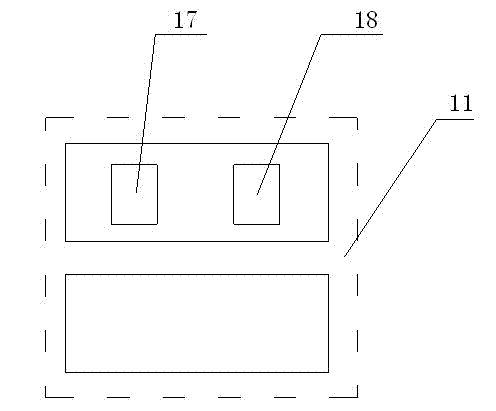

[0015] Such as figure 1 , figure 2 and image 3 As shown, an improved bag making machine includes: a raw material rack 1, the raw material rack 1 is connected with the control box 3 through a bracket 2, the control box 3 is provided with a speed control button 4, the control box 3 is provided with an axle 5, and the raw material The frame 1 is connected with the conveyor belt 6 through the axle 5, and the transmission belt 6 is provided with a color code photoelectric eye 7, a length adjustment device 8, a cutter 9, a punching device 10, a heat sealing device 11 and a cooling device 12. The rolling device 13 and the punching device 10 are divided into a perforating needle 14 and a bottom box 15, the side of the bottom box 15 is provided with an adjustment button 16, the perforating needle 14 is connected with the adjustment button 16, and the heat sealing device 11 is provided with a temperature control device 17 and pressure regulating device 18, speed control button 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com