Floating sanding machine

A technology of sanding machine and floating wheel, which is applied in the direction of abrasive belt grinder, grinding machine, metal processing equipment, etc. It can solve the problems that cannot meet the needs of sanding and polishing of products, and achieve the effect of ensuring quality and overcoming poor floating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

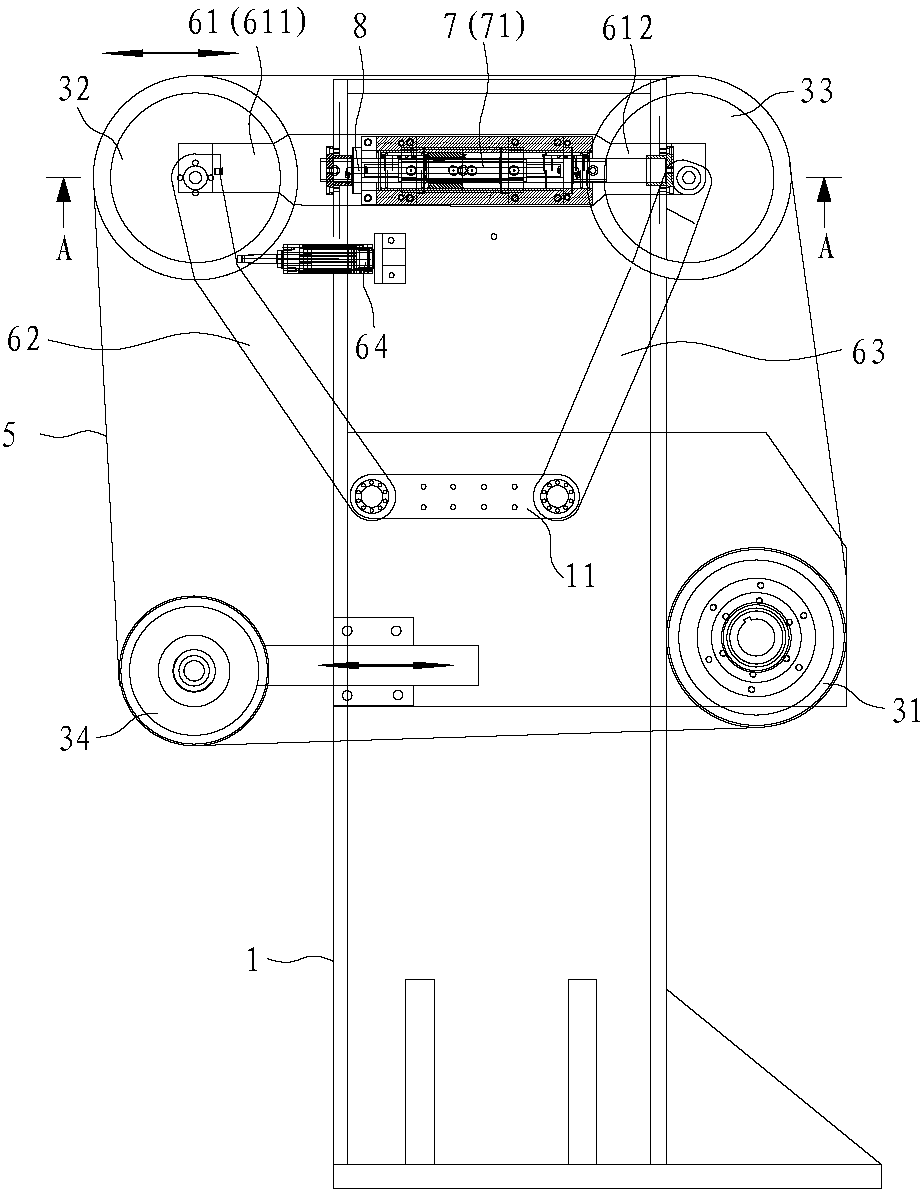

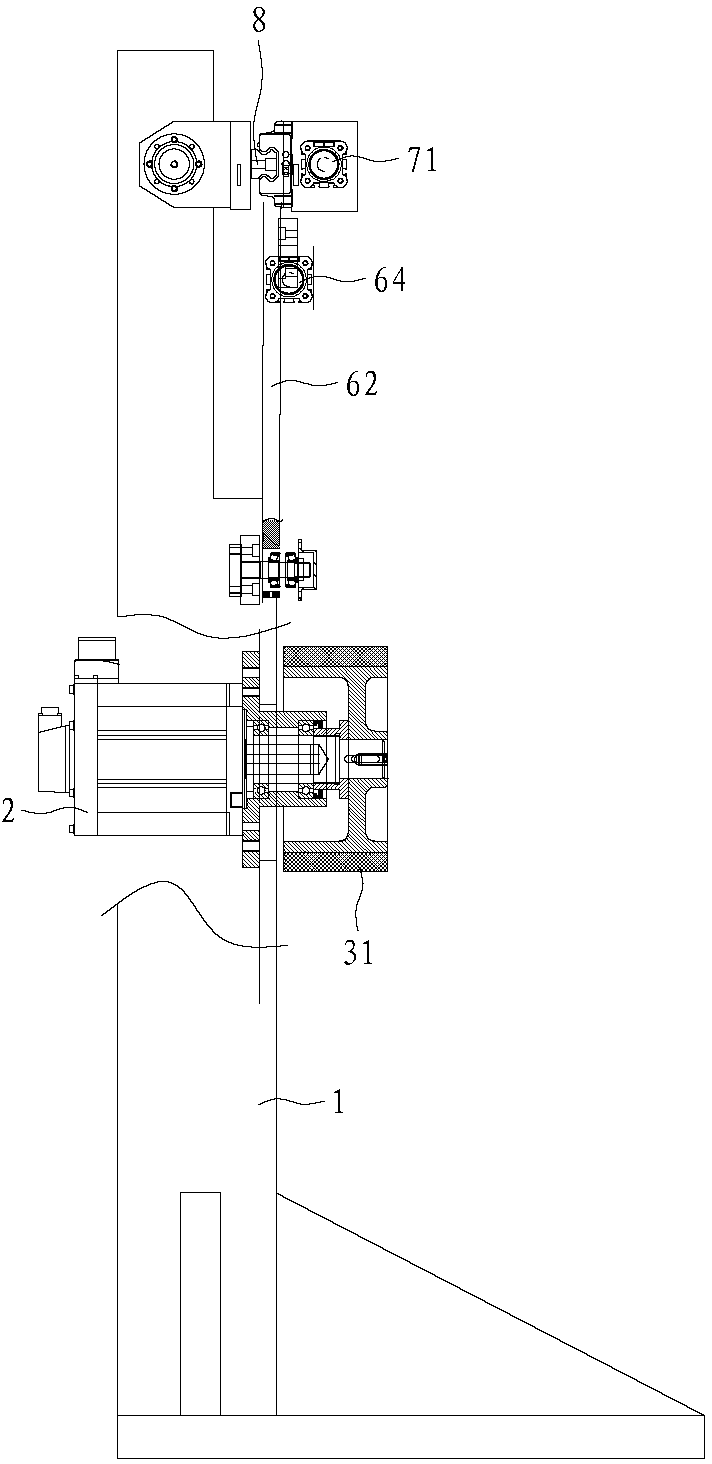

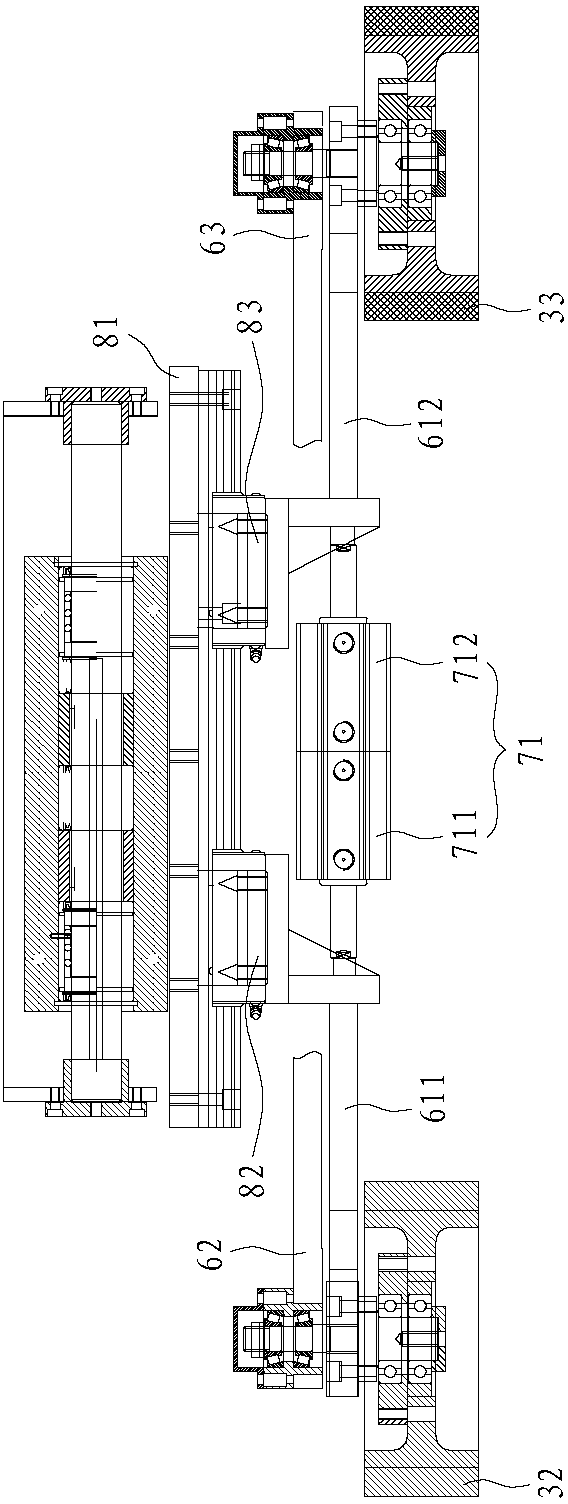

[0043] Such as Figure 1 to Figure 3 As shown, it is the first embodiment of a floating sander according to the present invention, including a frame 1, a polishing motor 2, a main drive wheel 31, a main floating grinding wheel 32, a slave floating wheel 33, and at least one abrasive belt drive Wheel 34, abrasive belt 5, connecting mechanism 61, front floating arm 62, rear floating arm 63, floating cylinder 64 and tension mechanism 7 for controlling the tension of abrasive belt 5.

[0044] The polishing motor 2 is connected to the main transmission wheel 31 in transmission, and the abrasive belt 5 is annular and is sleeved on the periphery of the main transmission wheel 31, the main floating grinding wheel 32, the floating wheel 33 and at least one abrasive belt driving wheel 34. In this embodiment, only one ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com