Head for cutting machine and cutting machine

A cutting machine and machine head technology, which is applied in the direction of cutting tools for shearing machine devices, metal processing machinery parts, feeding devices, etc. Knife repositioning and other issues to achieve the effect of improving service life and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

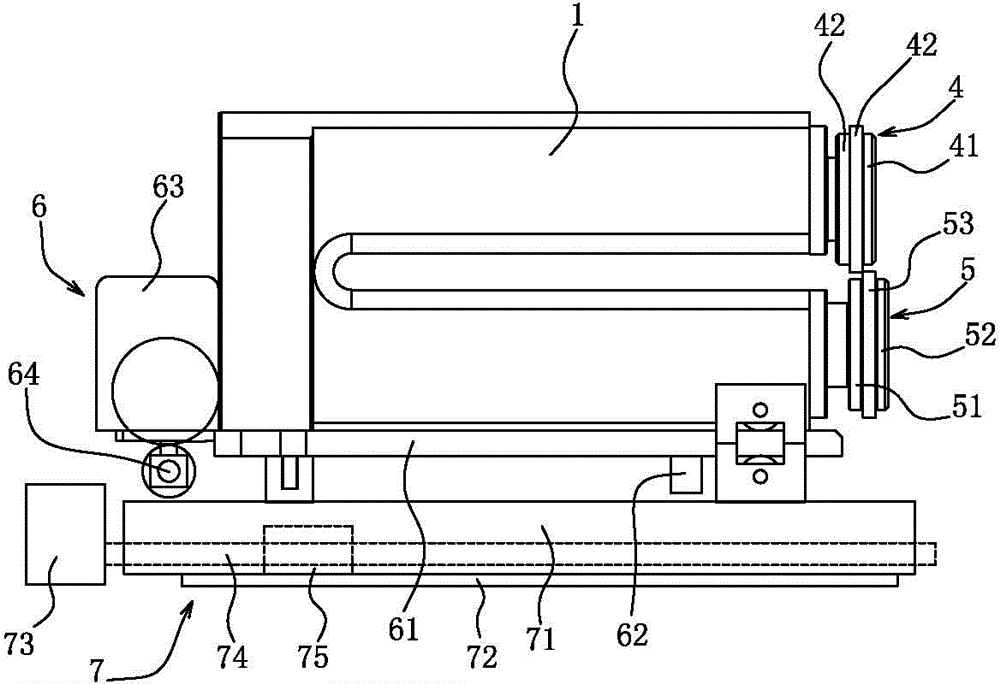

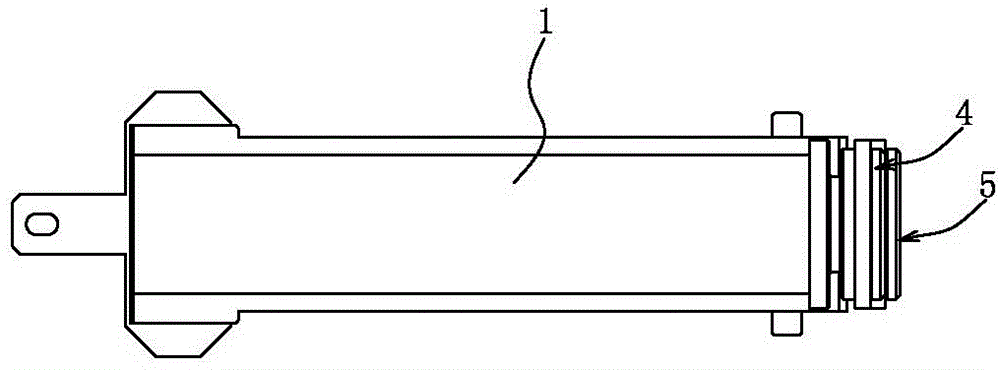

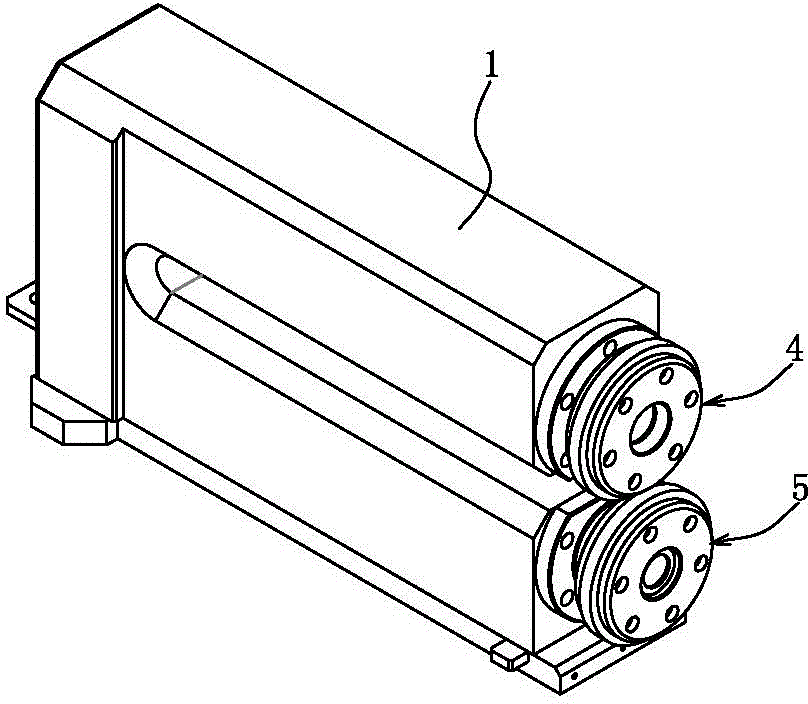

[0024] see Figure 1 to Figure 6 , a kind of embodiment that is used for the machine head of cutting machine that the present invention provides, comprises a tool head frame 1, the first main shaft 2 and the second main shaft 3 that are installed on the described tool head frame 1, are arranged on the The inner cutter head 4 at the end of the first main shaft 2 and the outer cutter head 5 arranged at the end of the second main shaft 3, the inner cutter head 4 includes a reference positioning plate 41 fixed on the end surface of the first main shaft 2 , the pressing plate 42 set on the end of the first main shaft 2 and the inner blade 43 between the reference positioning plate 41 and the pressing plate 42, the outer cutter head 5 includes a The reference positioning ring 51 at the top, the pressure ring 52 sleeved on the end of the second main shaft 3 and located outside the reference positioning ring 51 , and the outer blade 53 between the reference positioning ring 51 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com