The Method of Designing Multiple Overflow Trays by Equal Residence Time Method

A residence time and multiple overflow technology, applied in the direction of fractionation, etc., can solve the problems of short liquid residence time, affecting vapor-liquid distribution, affecting mass transfer efficiency, etc., to alleviate the amplification effect, improve back-mixing disturbance, and evenly distribute gas-liquid Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

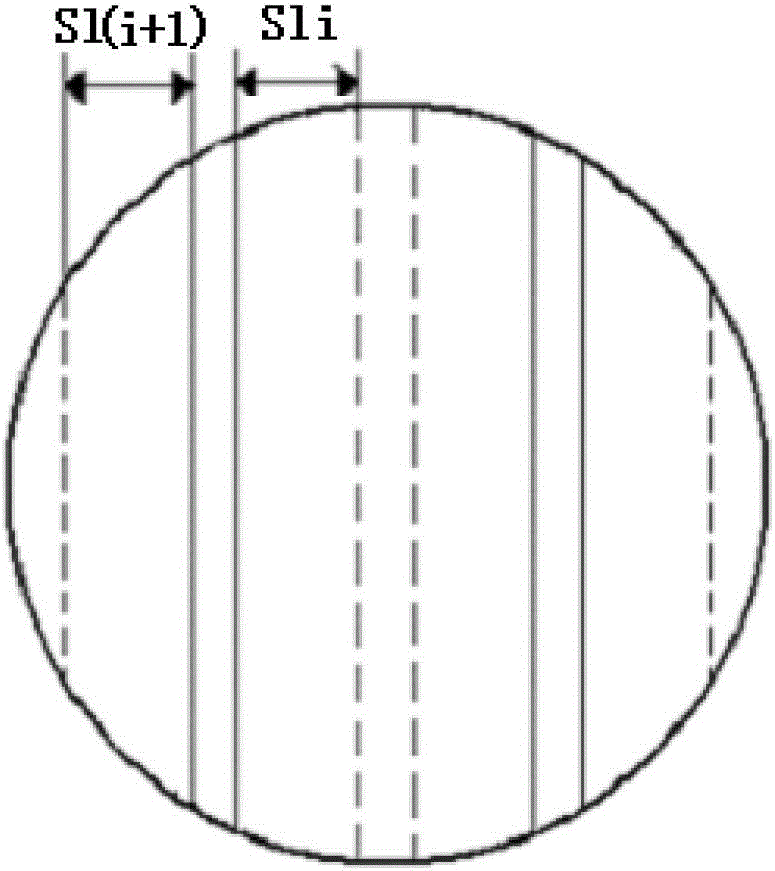

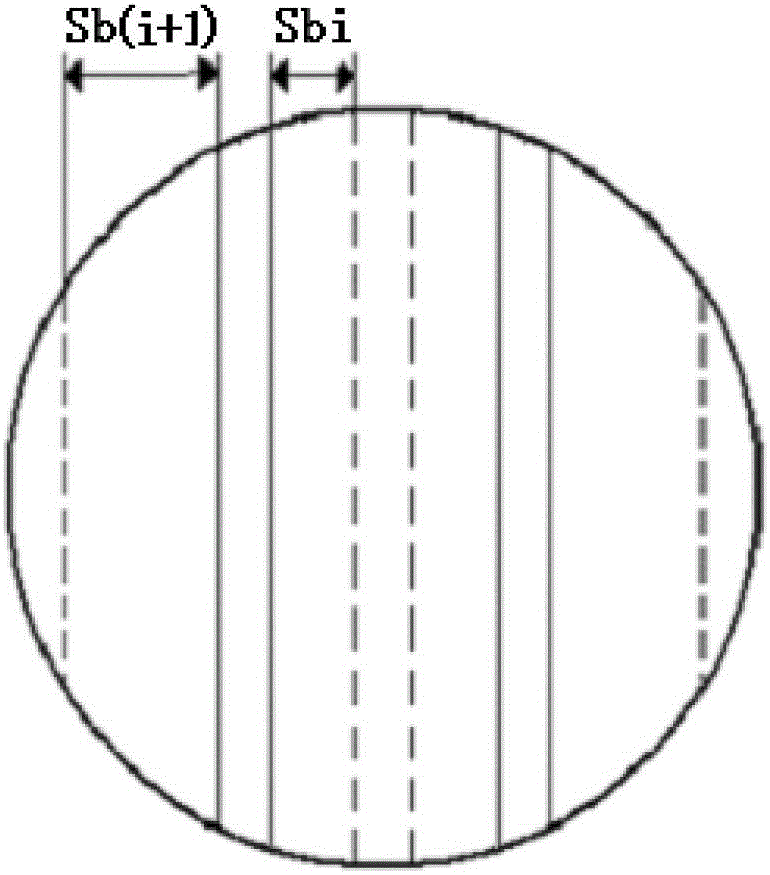

[0068] refer to Figures 1 to 1 5 further illustrate the embodiments of the present invention:

[0069] 1. The present invention is a kind of many overflow trays designed according to the residence time method, promptly calculates the flow path length of liquid flow in each bubbling area 3 by following formula, and designs many overflow trays 1 accordingly.

[0070] t i = Q i L i = A i h c l L i = S i l i ‾ h c ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com