Method for preparing green tea

A technology for green tea and tea leaves, applied in the field of green tea preparation, can solve the problems of tea type, color, taste and nutrient damage, tea color, aroma influence and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

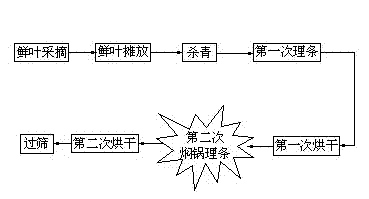

[0015] The preparation method of the green tea of the present invention comprises successively picking fresh leaves, spreading fresh leaves, finishing, first stripping, drying for the first time, stewing pot strips for the second time, drying for the second time, sieving, etc. process, in which the second stewing pot strip is the re-steaming pot strip after the initial drying, so that the dry tea will form an orchid shape after brewing, so as to achieve a high viewing effect. The whole process of making tea leaves does not need to be kneaded or pressed. , resulting in damage to the shape of the tea leaves.

[0016] It specifically includes the following steps:

[0017] First of all, pick the tea leaves. The raw materials are required to be small-leaf tea tree varieties that are more than 40 years old. The picking time is: spring tea is from the beginning of April to the end of May, and it can also be picked in late March. Picking standards: one bud and one leaf and a small a...

Embodiment 2

[0028] The method is the same as in Example 1, the only difference is that the inlet temperature of the green fixing machine reaches 155°C, the outlet temperature reaches 120°C, and the first drying temperature is 100°C, and then the leaves are properly thrown, and each barrel is thrown when the stewing pot is straightened. The amount of leaves is 2.5 kg. Shake first and then take, first fast and then slow. At the beginning, shake about 50 times per minute, and gradually reduce the speed to about 40 times per minute; high-grade fresh leaves are divided into three stages, and intermediate fresh leaves are divided into two stages. Can. When drying for the second time, the amount of leaves cast is 2.5 kg, and the temperature is at 120°C, and the leaves are turned over while drying until fully dry.

Embodiment 3

[0030] The method is the same as in Example 1, the only difference is that the inlet temperature of the fixing machine reaches 160°C, the outlet temperature reaches 120°C, the first drying temperature is 105°C and then the leaves are properly thrown, and each cylinder is thrown in when the stewing pot is straightened. The amount of leaves is 3 kg. Shake first and then take, first fast and then slow. At the beginning, shake about 60 times per minute, and gradually reduce the speed to 45 times per minute; high-grade fresh leaves are divided into three stages, and intermediate fresh leaves are divided into two stages. When drying for the second time, the amount of leaves cast is 3 kg, the temperature is at 125°C, and the leaves are turned over while drying until fully dry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com