Power switch cabinet

A technology of switchgear and electric power, applied in the field of electric switchgear, which can solve the problems of high humidity in the operating environment of equipment in the cabinet, moisture exchange and evaporation, threats to safe operation of equipment, etc., and achieve low cost, good dehumidification, maintenance and repair low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

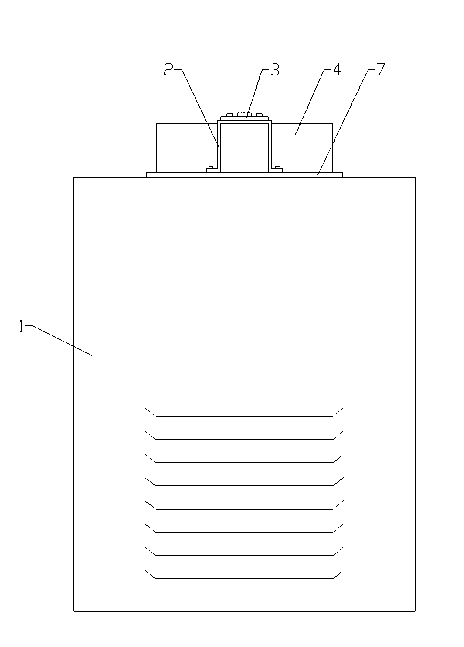

[0038] Example: as attached figure 1 And attached figure 2 As shown, the switch cabinet for electric power includes a cabinet body 1, and the cabinet body 1 is provided with an air inlet 8 and an air outlet hole 5, and an air exhaust device 4 is arranged at the air outlet hole 5.

[0039] The air inlet 8 is located at the rear of the cabinet body 1 .

[0040] Choice of air inlet 8 positions:

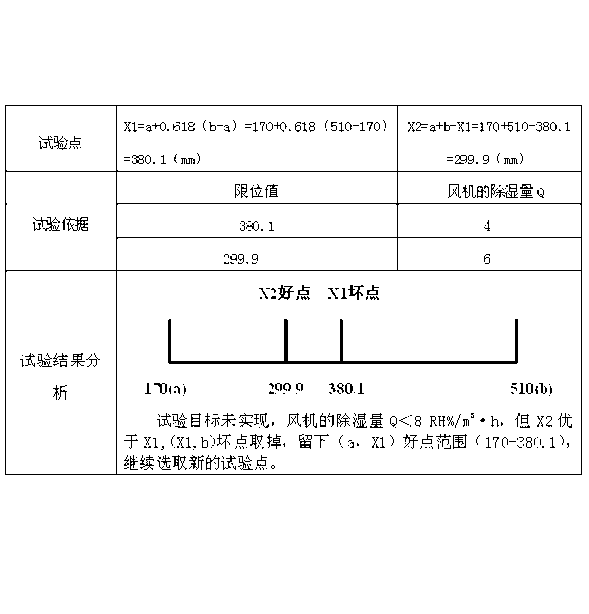

[0041]

[0042]

[0043] It can be seen from the above table that the air inlet 8 is located at the rear of the cabinet body 1, which has the best dehumidification effect and the largest safety distance.

[0044] The air inlet 8 is set at the rear of the cabinet 1, and the dehumidification effect is better than that of the air inlet 8. It is set at the top and front of the cabinet 1, which will not pose a safety threat to the operator, and the distance from the equipment in the cabinet 1 is also safe Require.

[0045] Air inlet 8 is the windproof louver air inlet.

[0046] C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com