Piezoresistive acceleration sensor with full-bridge micro-beam structure

An acceleration sensor, piezoresistive technology, applied in the field of piezoresistive acceleration sensor, can solve the problems of reducing the resonance frequency, affecting the measurement results, low sensitivity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

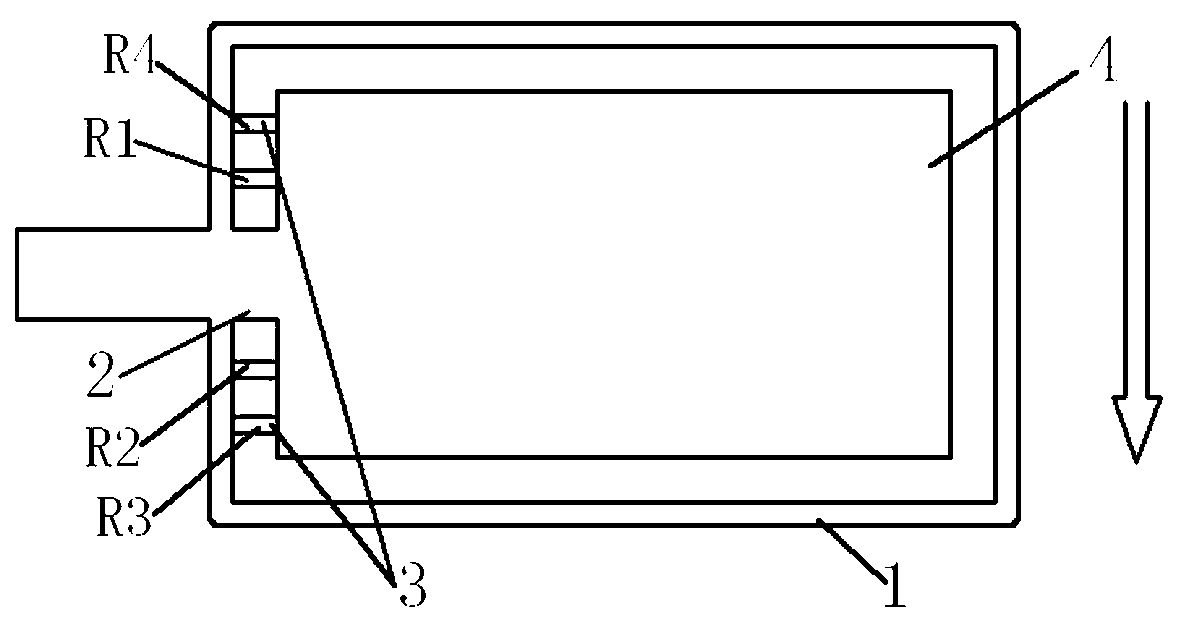

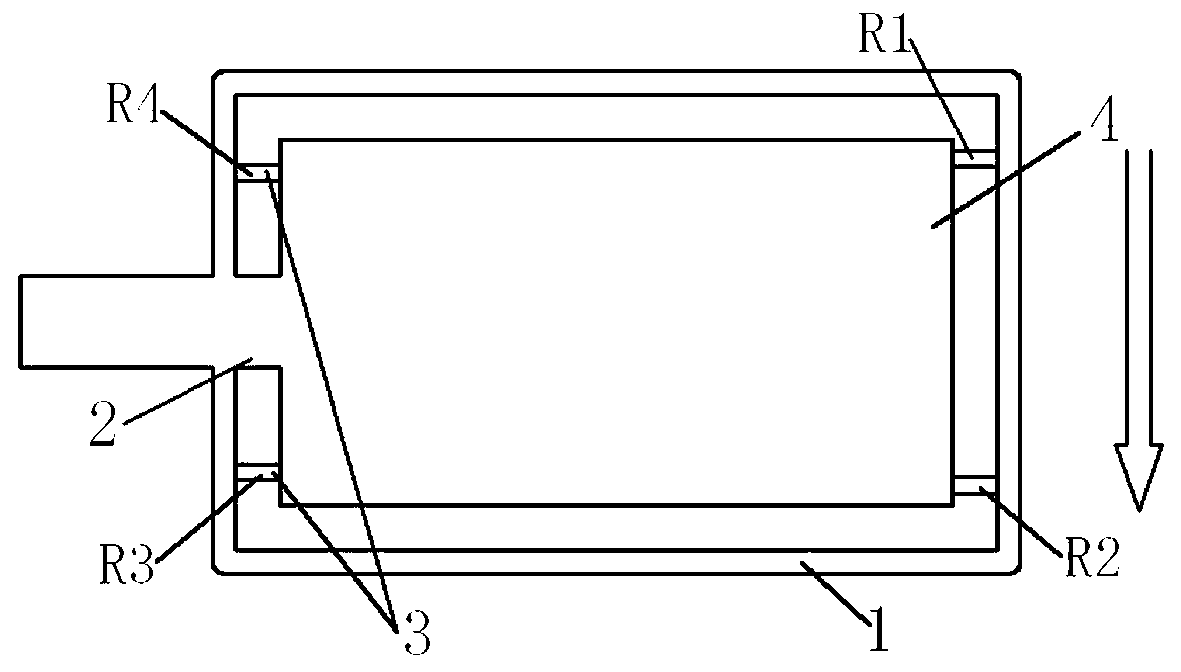

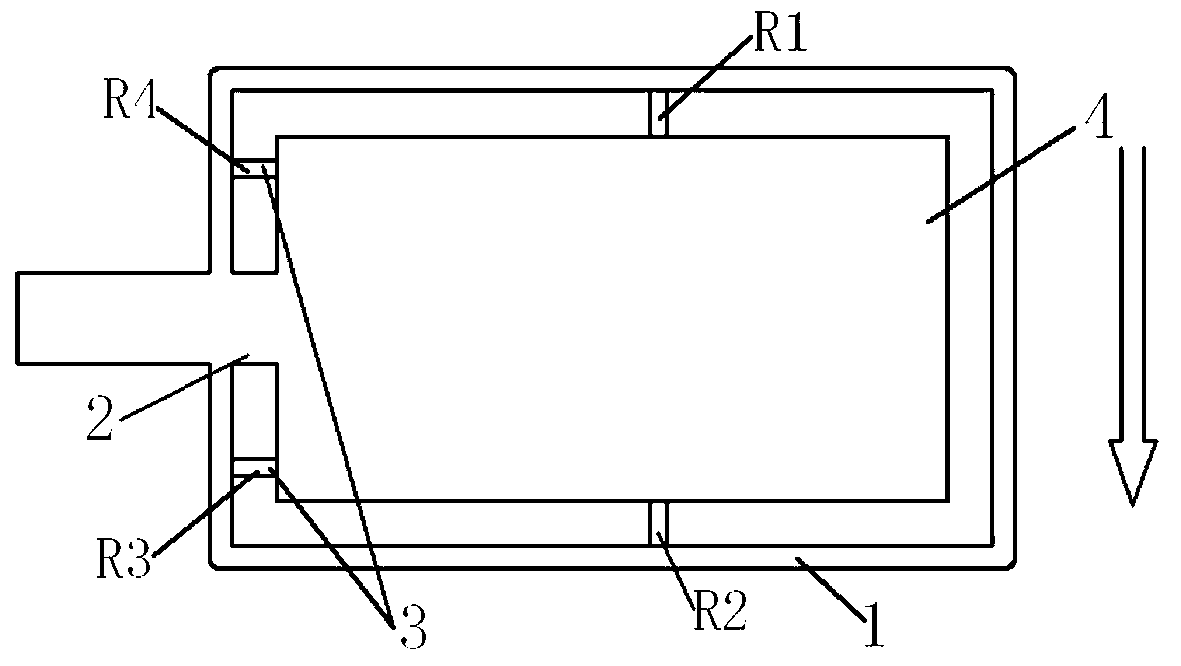

[0015] like figure 1 Shown is a specific embodiment one of the piezoresistive acceleration sensor with a full-bridge micro-beam structure of the present invention, including a frame 1, a cantilever beam 2, a micro-beam 3 and a mass block 4, and the cantilever beam 2 is on the axis of symmetry of the mass block 4, There are four micro-beams 3, which are symmetrically distributed on the edge of the mass block 4 with the axis of the cantilever beam 2 as the axis, connecting the mass block and the frame, so as to ensure that the resistance of the two resistances on one side of the cantilever beam 2 increases during the working process, while the other The resistance values of the two resistors on one side decrease, and the change values of the four resistors are equal. The four microbeams 3 in this embodiment are all symmetrically distributed on the side where the mass block 4 is connected to the cantilever beam 2 . Among them, the four microbeams 3 form piezoresistors R1, R2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com