Aggregate three-dimensional structure discrete element generating method

A three-dimensional shape, discrete element technology, applied in the direction of analysis of materials, instruments, etc., can solve the problem of not being able to establish contact with actual aggregates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

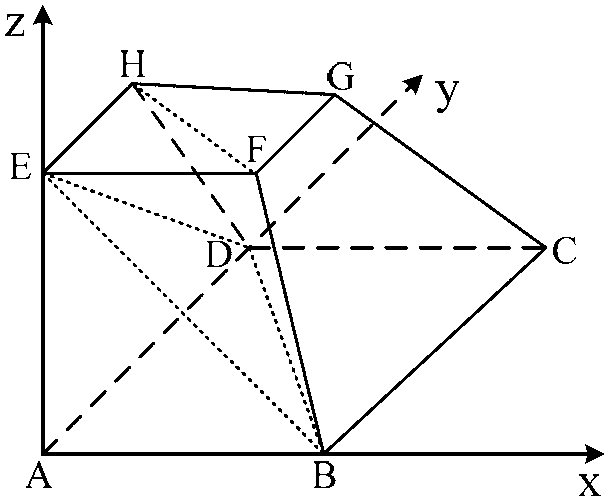

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

[0014] Aggregate three-dimensional shape discrete element generation method, the aggregate particles are set as a hexahedron, pentahedron or tetrahedron formed by arranging several layers of spheres of equal particle size regularly, and at least There are three sides perpendicular to each other, and the three sides have a common endpoint, and the three-dimensional size characteristics of the aggregate particles are characterized by the length of the three sides, so as to include three of the three perpendicular planes of the three sides Angles characterize the angular character of the aggregate particles.

[0015] Taking the hexahedron as a basic structure, the hexahedron has at least one pair of parallel faces, and the two sides of one of the pair of parallel faces are two of the three mutually perpendicular sides, so Two ends of the other of the three mutually perpe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com