Center-free arc bending radius measuring ruler and bend pipe bending radius measuring method

A technology of bending radius and measurement method, which is applied to measurement devices, mechanical measurement devices, instruments, etc., can solve problems such as difficulty for inspectors and equipment supervisors to grasp and use, poor repeatability of pipeline bending radius, and large randomness. Observation and supervision, easy to grasp, the effect of simple tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

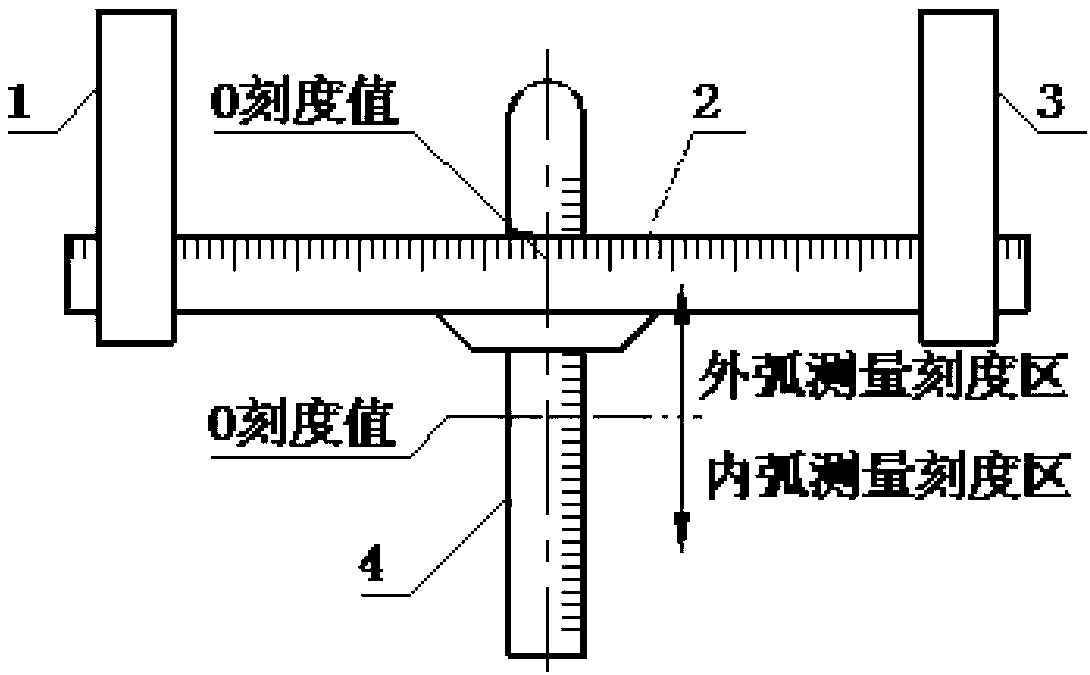

[0032] Such as figure 1 Shown, a kind of centerless circular arc bending radius measuring ruler of the present invention, it comprises beam 2, left supporting leg 1, right supporting leg 3 and telescopic ruler 4. The crossbeam 2 is arranged horizontally, and the two ends of the crossbeam 2 are respectively symmetrically connected with a left outrigger 1 and a right outrigger 3 , and a telescopic ruler 4 is connected at the center of the crossbeam 2 .

[0033] The left supporting leg 1, the right supporting leg 3 and the telescopic ruler 4 are all perpendicular to the beam 2.

[0034] The left supporting leg 1 and the right supporting leg 3 are equal in length, and the distance W from the left supporting leg 1 and the right supporting leg 3 to the center of the beam 2 is equal;

[0035] Between the left supporting leg 1, the right supporting leg 3 and the crossbeam 2, it can be an adjustable sliding type, or a fixed type.

[0036] There are scale marks on the beam 2 and the t...

Embodiment 2

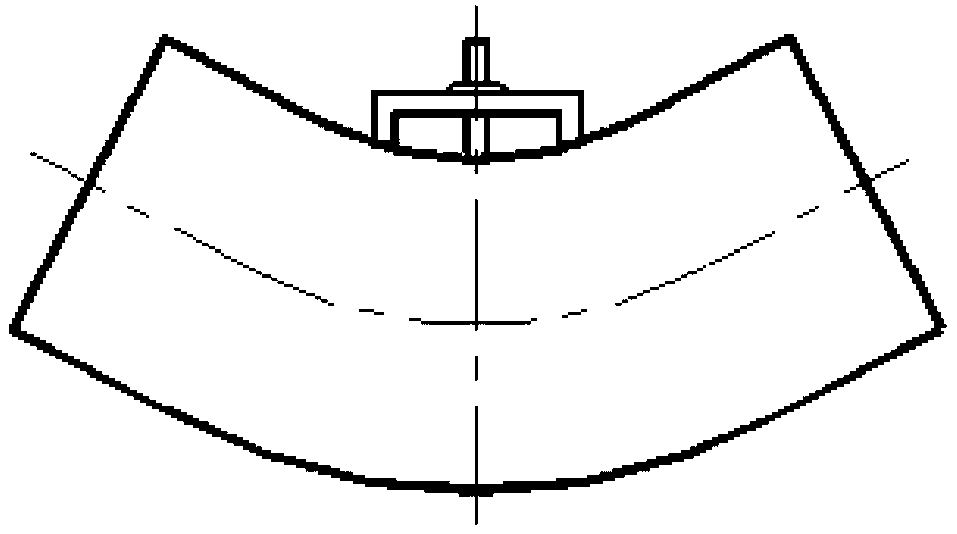

[0039] A method for measuring the bending radius of an elbow using the centerless circular arc bending radius measuring ruler described in Embodiment 1, see figure 2 with image 3 , when measuring the bending radius of the outer arc of the elbow, see Figure 4 with Figure 5 ;

[0040] Specifically include the following steps:

[0041] (1) On the center line of the inner or outer arc of the elbow, divide the arc length of the center arc from 2 to 20 within the arc length from the bending point at one end to the bending point at the other end (for example: 2, 10 or 20 equal divisions, the specific number of equal divisions can be determined according to the accuracy requirements), forming multiple equal division points; when there is no obvious starting point, the arc length of the mid-arc surface is used instead of from the starting point of one end to the other end The arc length of the mid-arc surface within the arc length of the inflection point;

[0042] (2) Use a ce...

Embodiment 3

[0048] Taking the hot section of a main pipeline of a certain project as an example below, the present invention will be further described in conjunction with the accompanying drawings.

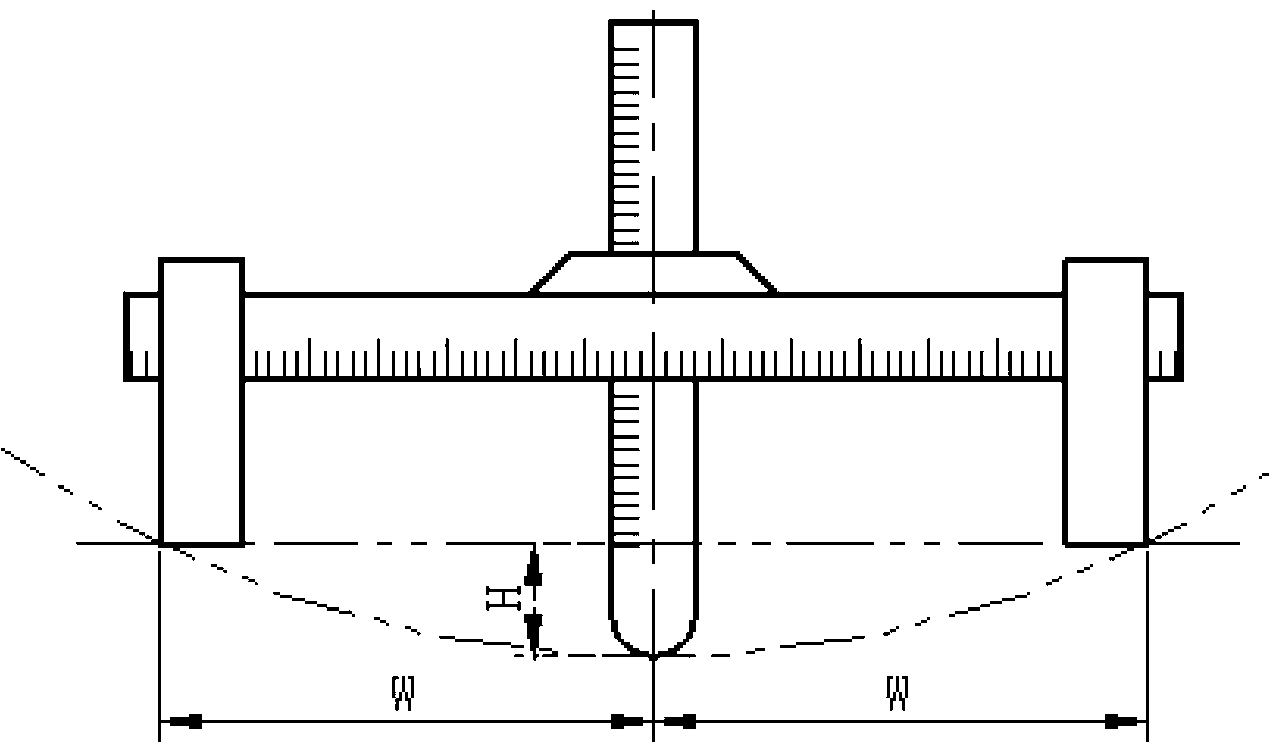

[0049] (1) Use a steel plate to make a simple measuring ruler for arc bending radius without a center, such as Image 6 Said, where W=300mm, E=120mm.

[0050] (2) According to the design drawing of the hot section of the main pipeline, the theoretical design length of the outer arc of the elbow part of the hot section of the main pipeline is calculated to be 1876mm.

[0051] (3) According to the design theoretical arc length, find out the corresponding arc length range on the outer arc of the hot section elbow of the main pipeline, and perform 10 equal divisions to obtain 11 equal division points, as shown in Figure 7 shown.

[0052] (4) Measure the distance L between the center of the beam length and the surface of the hot section A of the main pipe with the simple centerless arc bending ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com