Deep hole crack control blasting method for grouting reinforced surrounding rock

A technology of controlling blasting and grouting reinforcement, applied in blasting and other directions, can solve the problems of how much the grouting strength is increased, no practical application, different grouting effects, etc., and achieve the effect of reducing the number and expanding the diffusion range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

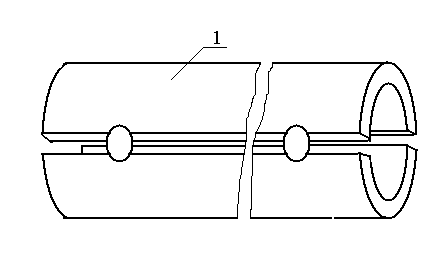

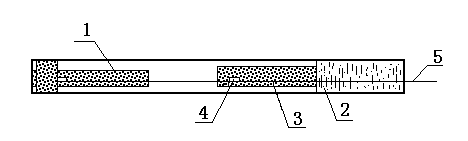

[0016] Such as figure 1 , figure 2 As shown, in a rock mass slope project, the rock mass is dominated by limestone, among which, the rock solidity coefficient f=6-7, the rock layer inclination angle is about 75 degrees, and the water content is relatively large. There is water 2 meters below the surface layer. After the excavation, the rock formation of the slope is unstable, and the slope outside the slope is reserved, and a drilling rig is used to drill holes with a diameter of 70 mm, a depth of 6 meters, and a distance of 6 meters between adjacent holes. Put the charge tube 1 in the borehole, and load the explosive coil 3 in the charge tube 1. The charge tube 1 is formed by lap welding of two arc-shaped plates, and the uncoupling coefficient of the explosive coil 3 is 1.5, the line charge density is 1.1 kgm -1 , tie the detonating cord on the loaded explosive volume 3, and after the length of the explosives installed with the detonating cord reaches the requirements of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com