Multi-station turntable type special drilling machine

A multi-station, turntable technology, used in boring/drilling, drilling/drilling equipment, metal processing machinery parts, etc., can solve the problems of processing technology, difficult to guarantee accuracy, low processing efficiency, etc. The effect of high precision, improved processing efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

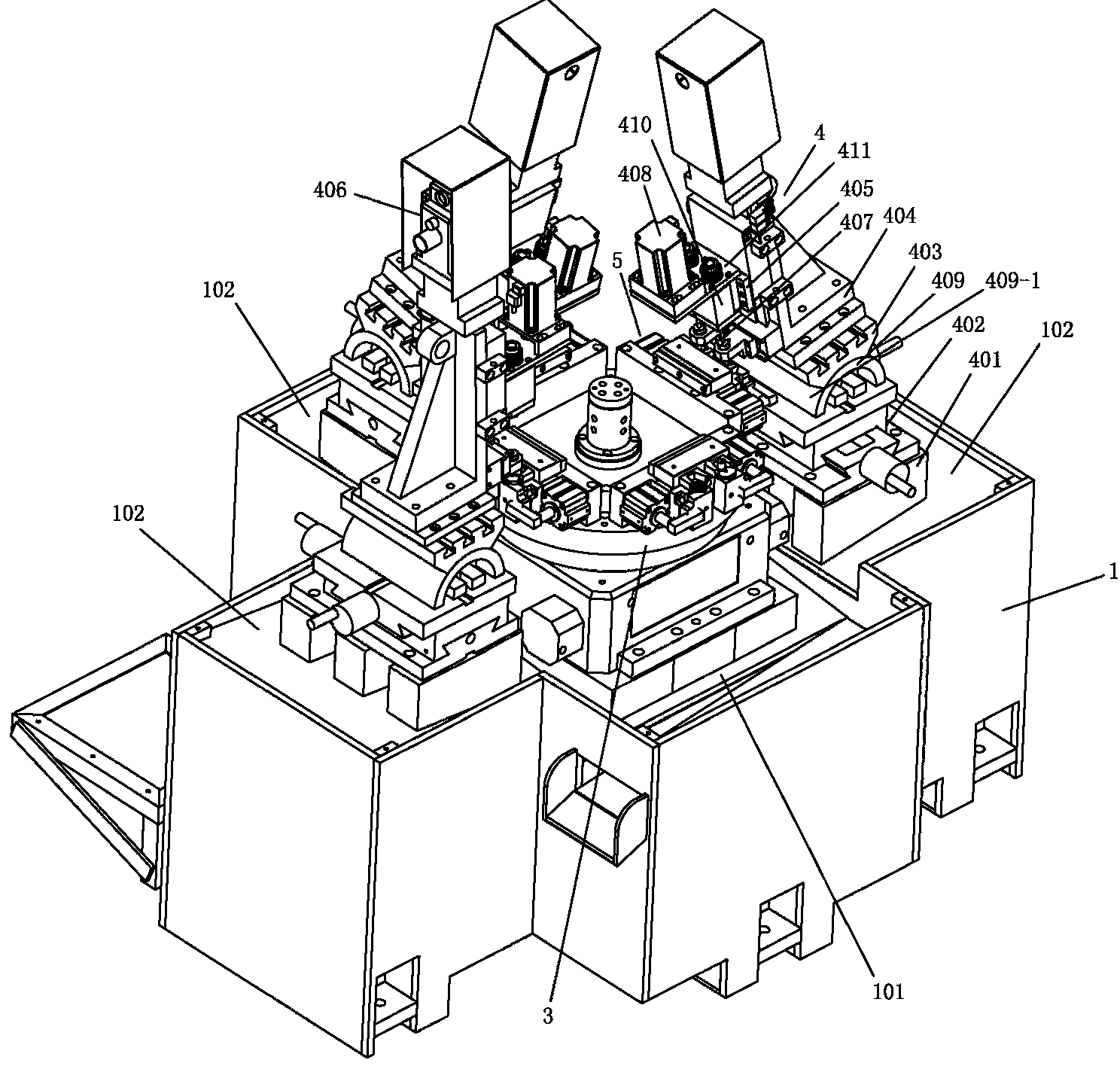

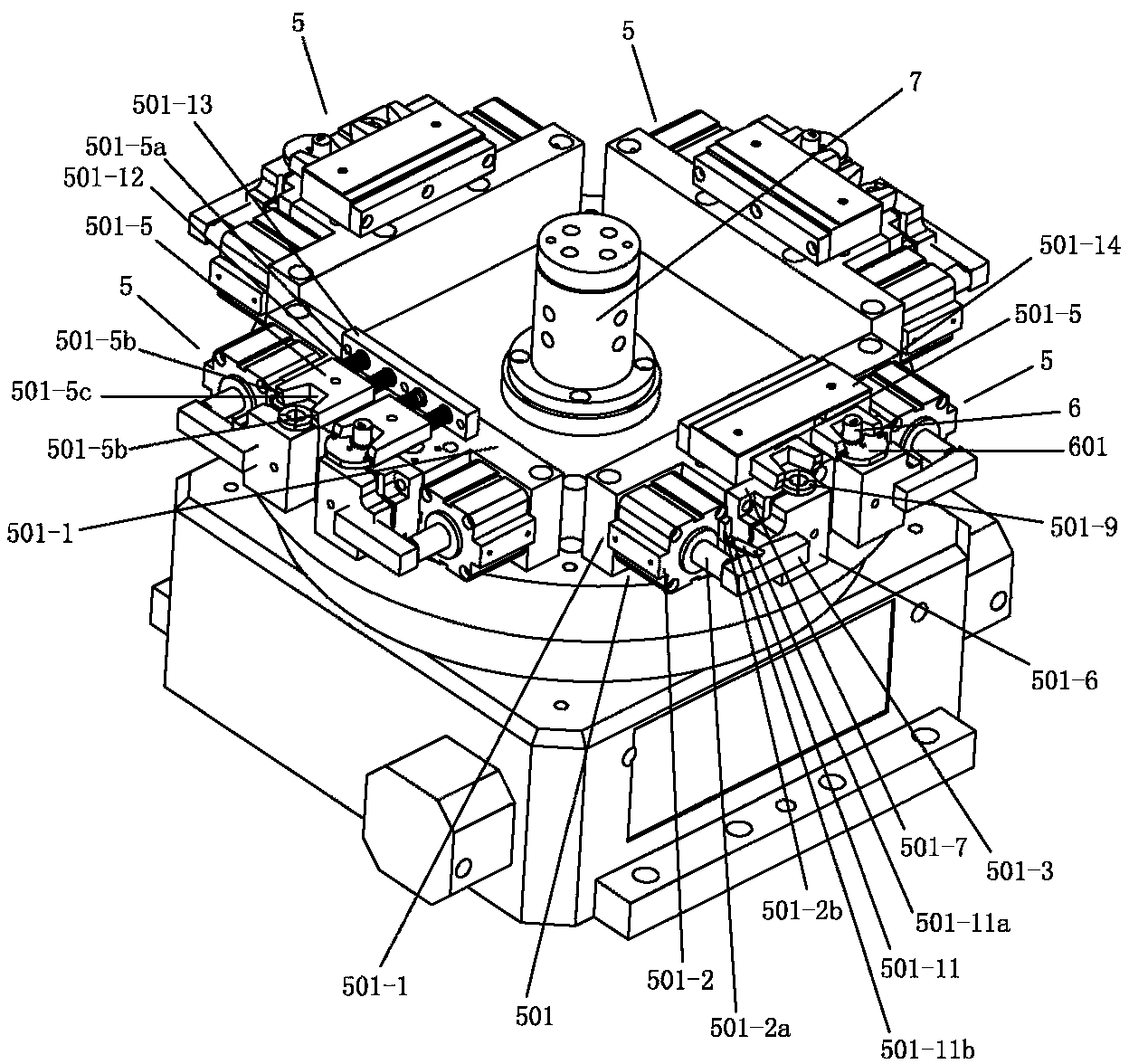

[0024] Such as Figures 1 to 3 As shown, a multi-station turntable vertical drilling machine, including a fuselage 1, is characterized in that, the center of the fuselage 1 is fixed with an angle dividing table 2, and a plurality of clamps are arranged along the circumferential direction of the angle dividing table 2 The device 5 is provided with a plurality of processing stations 102 and a clamping station 101 corresponding to the fuselage of the plurality of fixture devices 5, and an independent drill shaft feeding device 4 is provided on each processing station 102;

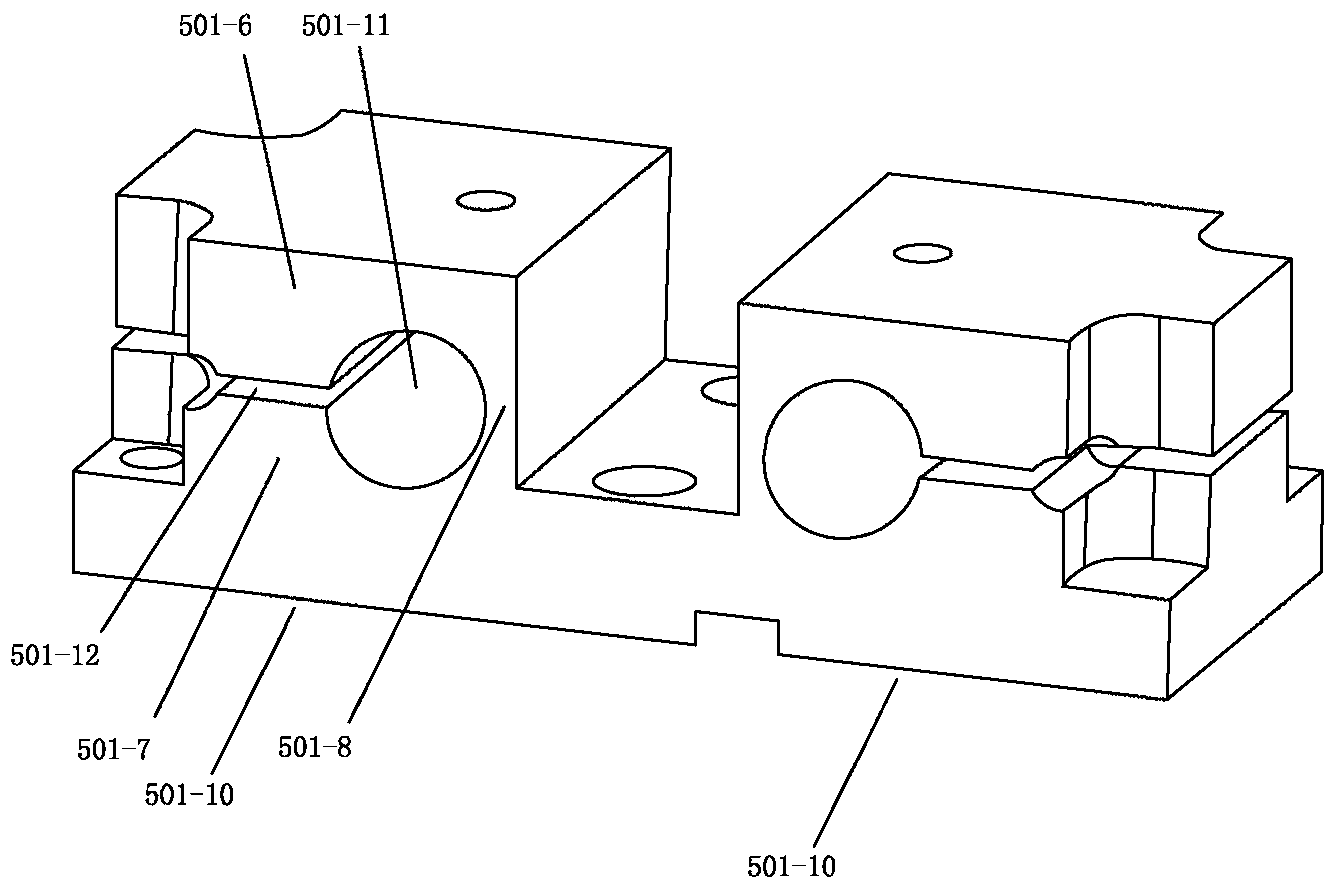

[0025] The clamp device 5 is provided with at least one clamp 501, and each clamp 501 is composed of a clamp fixing plate 501-1, a clamp cylinder 501-2, a cylinder pressure plate 501-3, an adjustable clamping seat and an elastic positioning slider 501-5. Composition, the clamp fixing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com