Hand-operated Chinese chestnut shucking machine

A technology of peeling machine and chestnut, applied in the field of agricultural machinery, to achieve the effect of simple structure, simple operation, and convenient removal of chestnut shell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

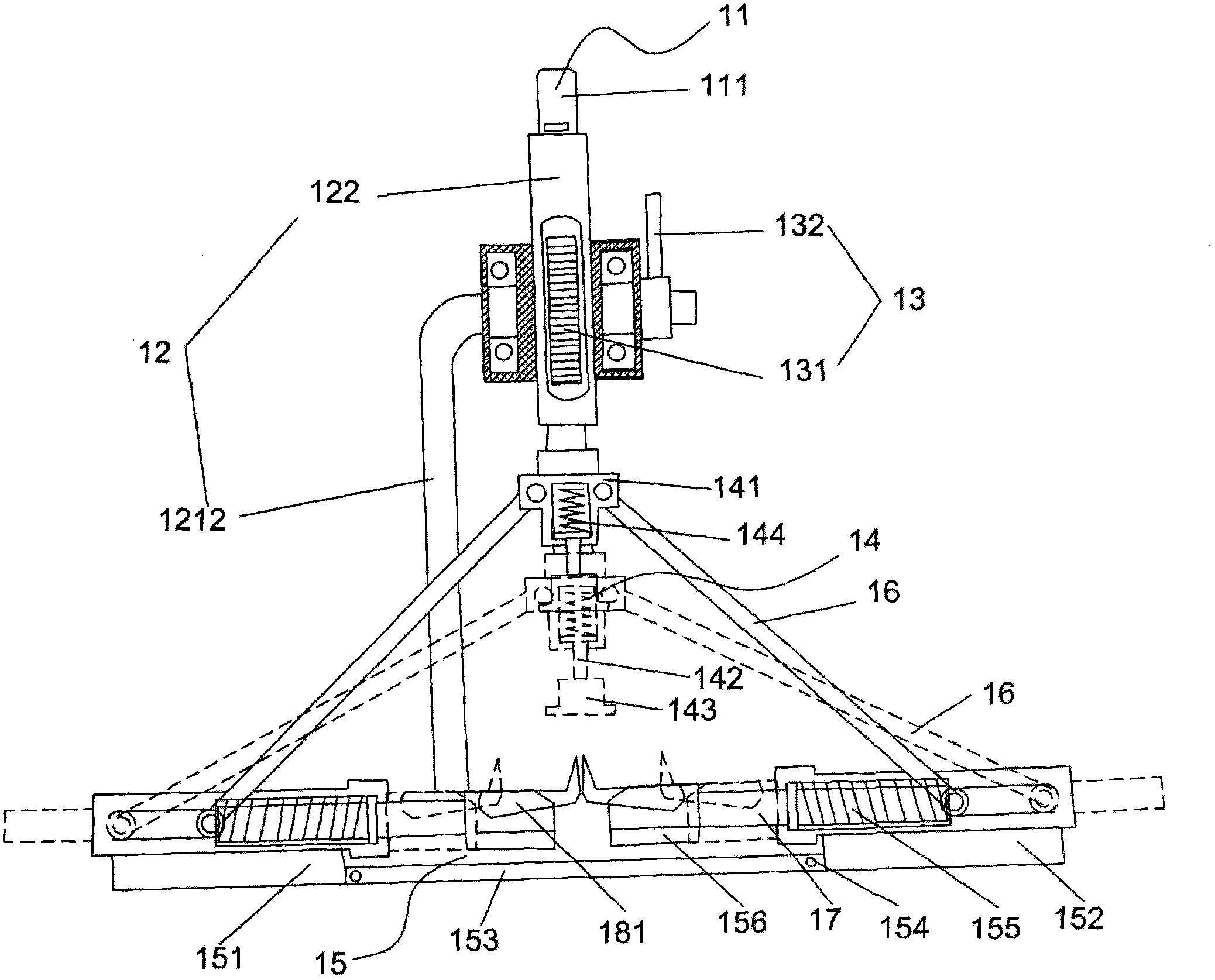

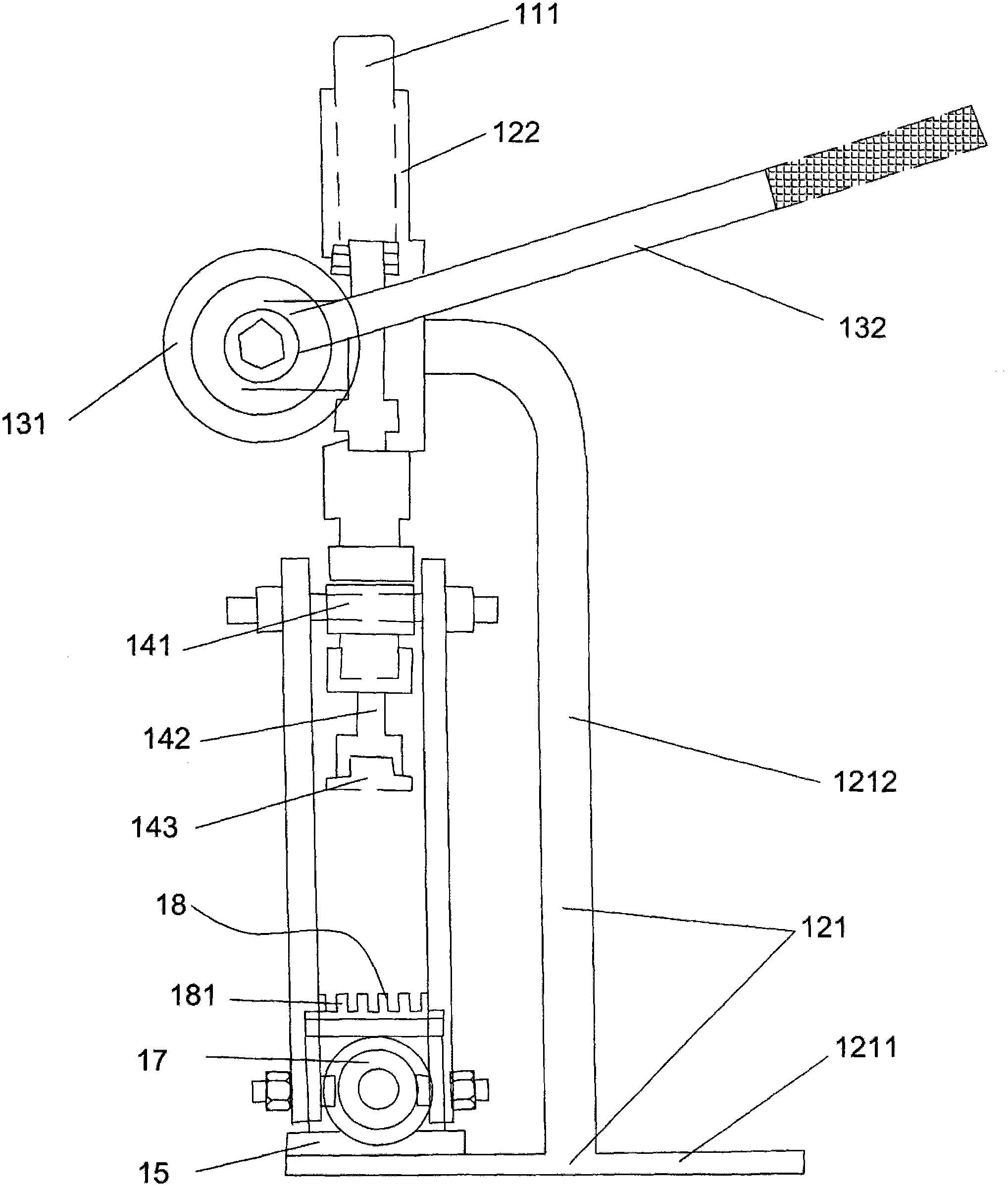

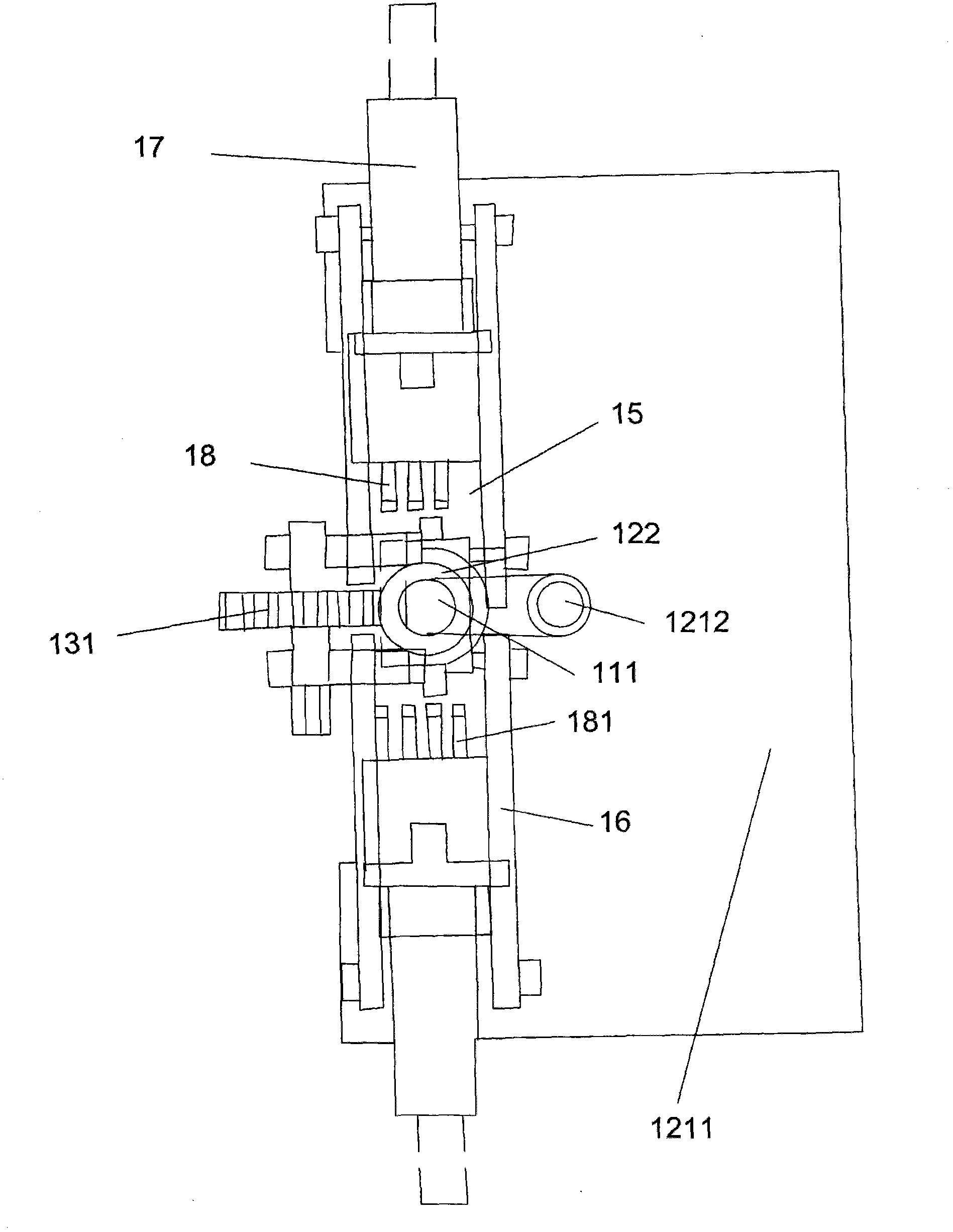

[0024] Present embodiment provides a kind of manual chestnut peeling machine, as Figure 1-3 As shown, the chestnut sheller includes a pressing bar assembly 11 that reciprocates up and down, a bracket assembly 12 for supporting the pressing bar assembly 11 to reciprocate up and down, and a transmission assembly 13 that drives the pressing bar assembly 11 to reciprocate up and down. The support assembly 12 includes a support frame 121 and a sliding sleeve 122 fixed on the support frame. The support frame 121 includes a horizontal bottom plate 1211 and a support rod 1212 fixed on the bottom plate 1211 and perpendicular to the bottom plate 1211. The shape of the support rod 1212 is similar to that of a basketball stand. The sliding sleeve 122 is fixed on the support rod 1212. The sliding sleeve 122 is straight cylindrical with openings at both ends. The sliding sleeve 122 is perpendicular to the bottom plate 1211; The pressing rod assembly 11 includes a rack 111 that slides up an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com