Cable bush

A cable wire and cable technology, which is applied in the direction of electrical components, electrical equipment structural parts, electrical equipment shells/cabinets/drawers, etc., can solve the problems of bushings and cables falling off, and achieve the prevention of cables falling off, simple assembly, and lightening The effect of operational burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

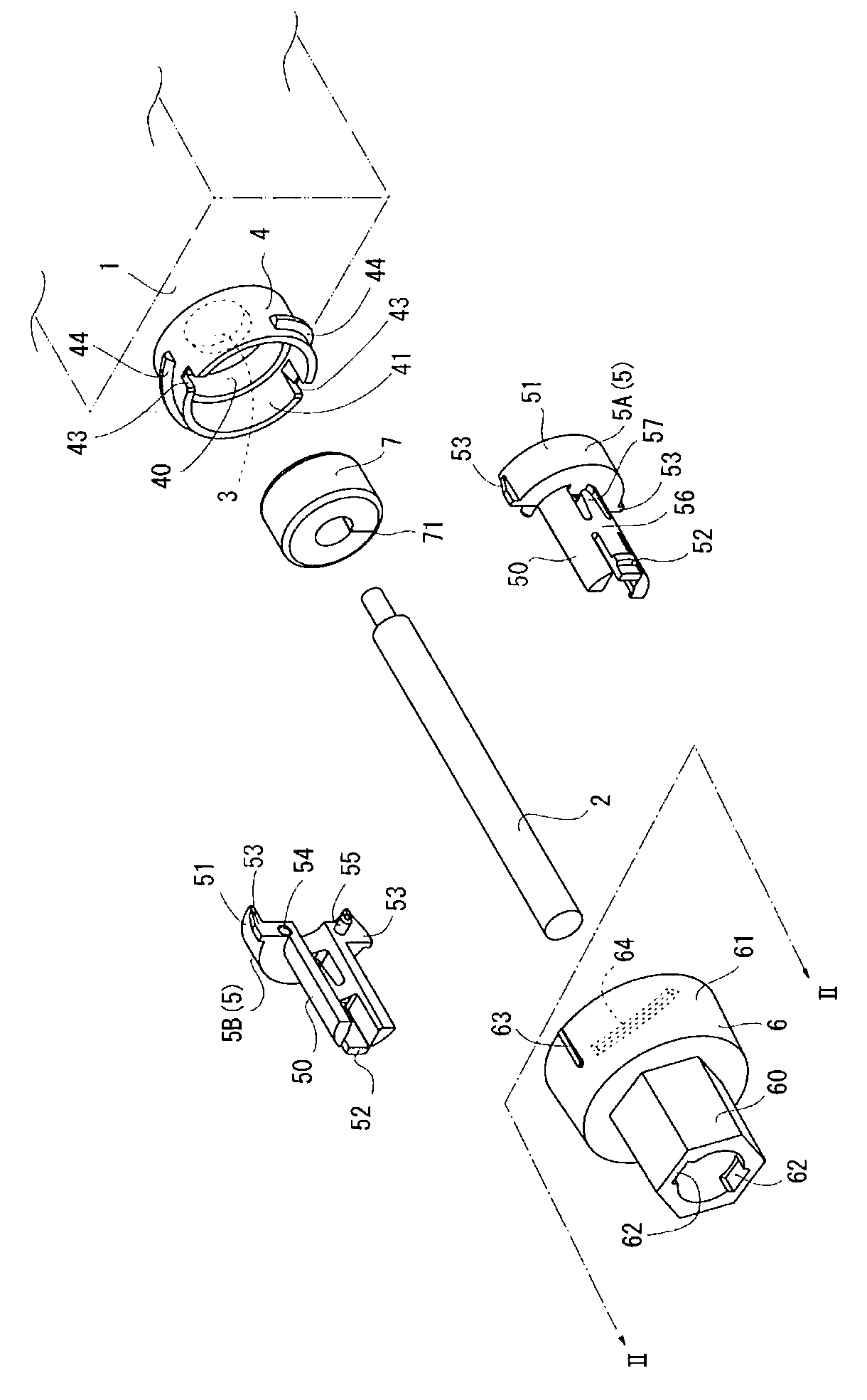

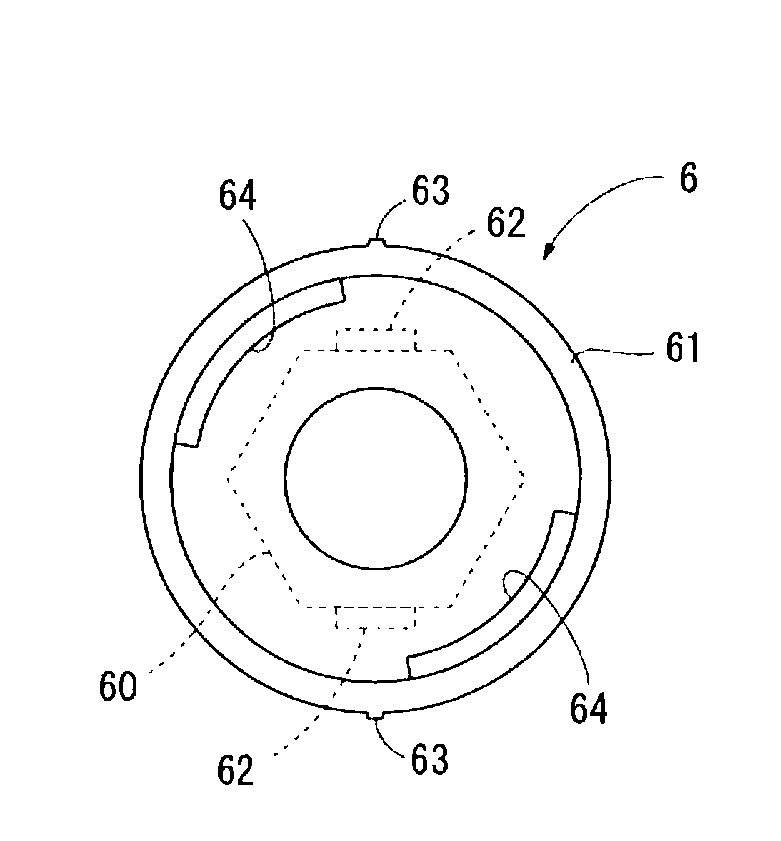

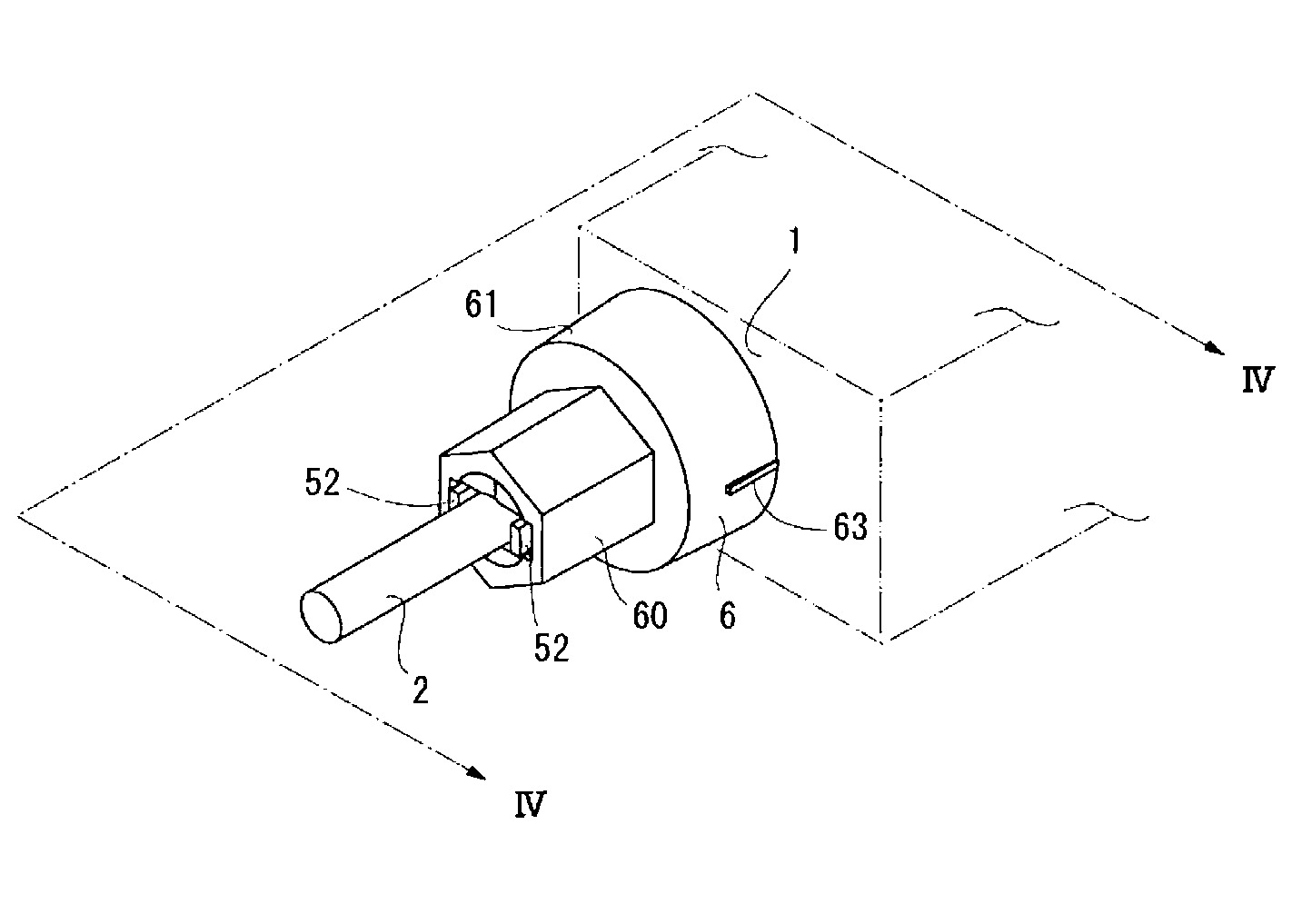

[0050] Such as figure 1 As shown, the cable tie in this embodiment is a bushing for the cable 2 to pass through the housing 1 . This cable tie includes: a through hole 3 ; a base member 4 ; a cable holding member 5 ; a cover member 6 and a sealing member 7 .

[0051] The case 1 is an outer case made of synthetic resin. Inside, for example, electronic components and an electronic substrate on which the electronic components are mounted are accommodated.

[0052] The cable 2 is electrically connected to the electronic components and the electronic substrate in the casing 1, and connected to external devices through the cable tie.

[0053] The through hole 3 is a hole provided on the wall of the housing 1 for the cable 2 to pass through. The outer diameter of the through hole 3 is larger than that of the cable 2 , so that the cable 2 can pass through without abutting against the through hole 3 .

[0054] The base member 4 is formed as a cylindrical body concentric with the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com