Current limiting element and light emitting diode device

A technology of light-emitting diodes and current-limiting components is applied in lighting devices, emergency protection circuit devices for limiting overcurrent/overvoltage, electrical components, etc. Achieve the effect of avoiding LED high heat, avoiding LED burning, and prolonging the service life of LED.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

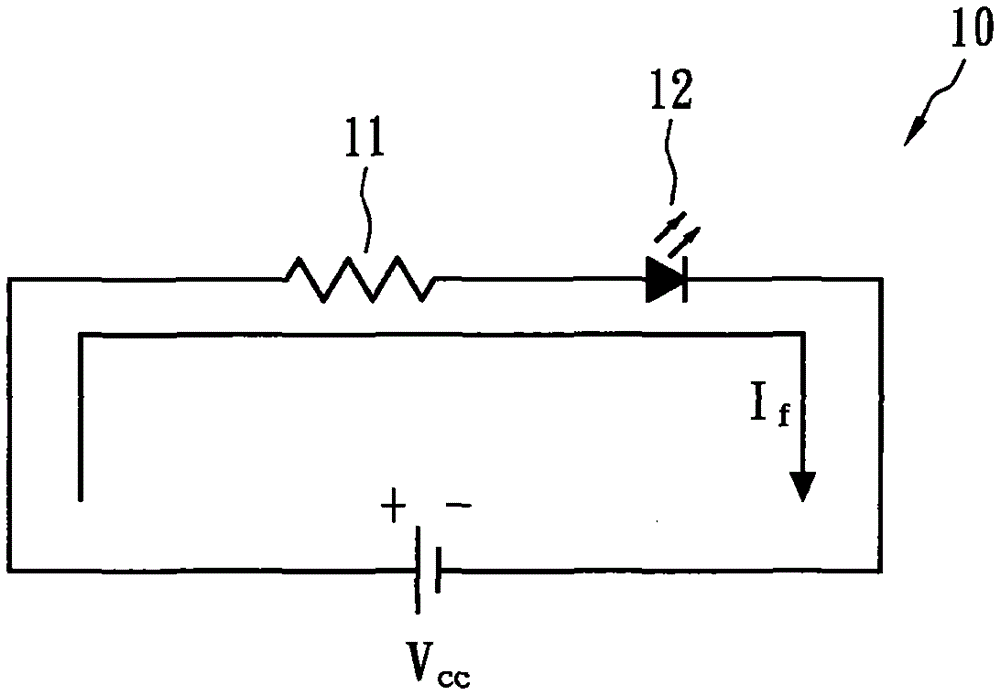

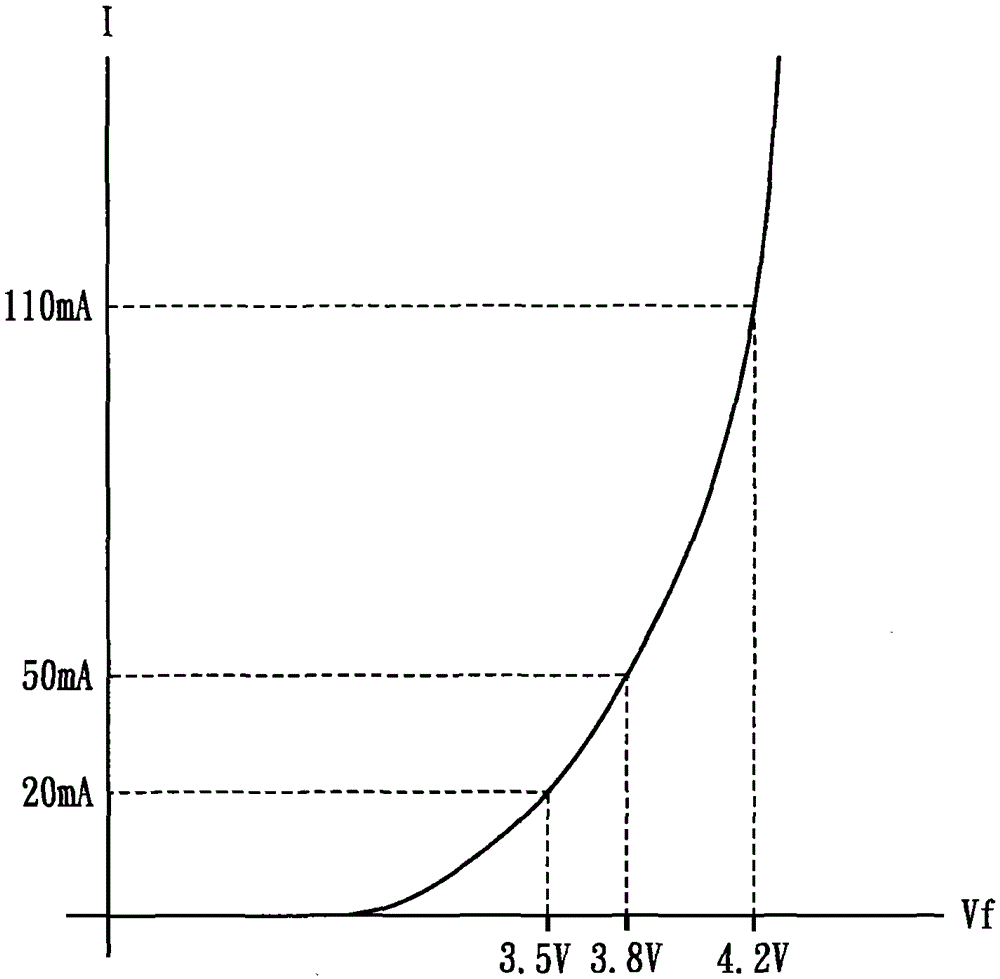

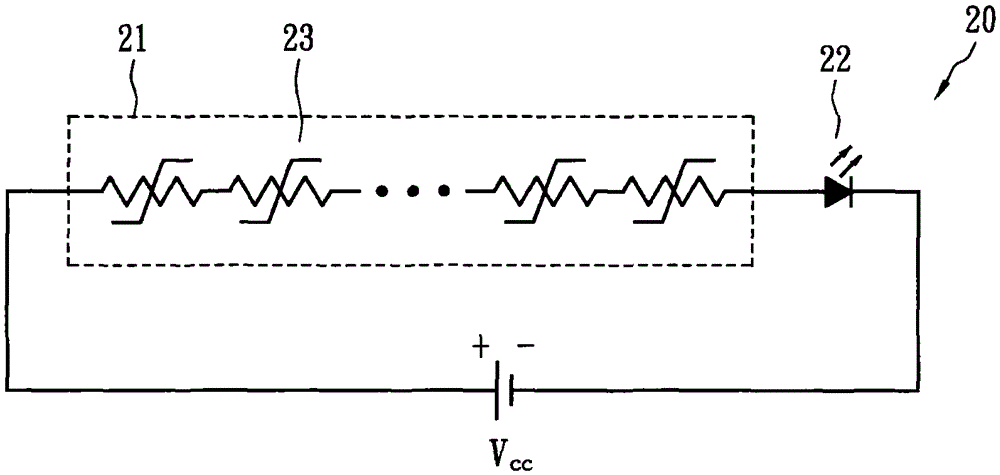

[0024] In order to make the above-mentioned and other technical content, features and advantages of the present invention more obvious and understandable, the following specifically cites relevant embodiments, together with the attached drawings, for detailed description as follows:

[0025] Since the resistance of conductive composite materials with positive temperature coefficient (PositiveTemperatureCoefficient; PTC) characteristics responds sensitively to temperature changes, it can be used as a material for current sensing elements and has been widely used in overcurrent protection elements or circuit elements. When an over-current or over-temperature phenomenon occurs in a circuit or battery, its resistance value will instantly increase to a high resistance state (at least 102Ω), and the excess current will be reduced. The temperature corresponding to the instantaneous rise of the resistance is called the trigger critical temperature. Before the trigger critical temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com