X-ray inspector

An inspection device and X-ray technology are applied in measuring devices, material analysis using radiation, and material analysis using wave/particle radiation, etc. Check the shape of the object, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

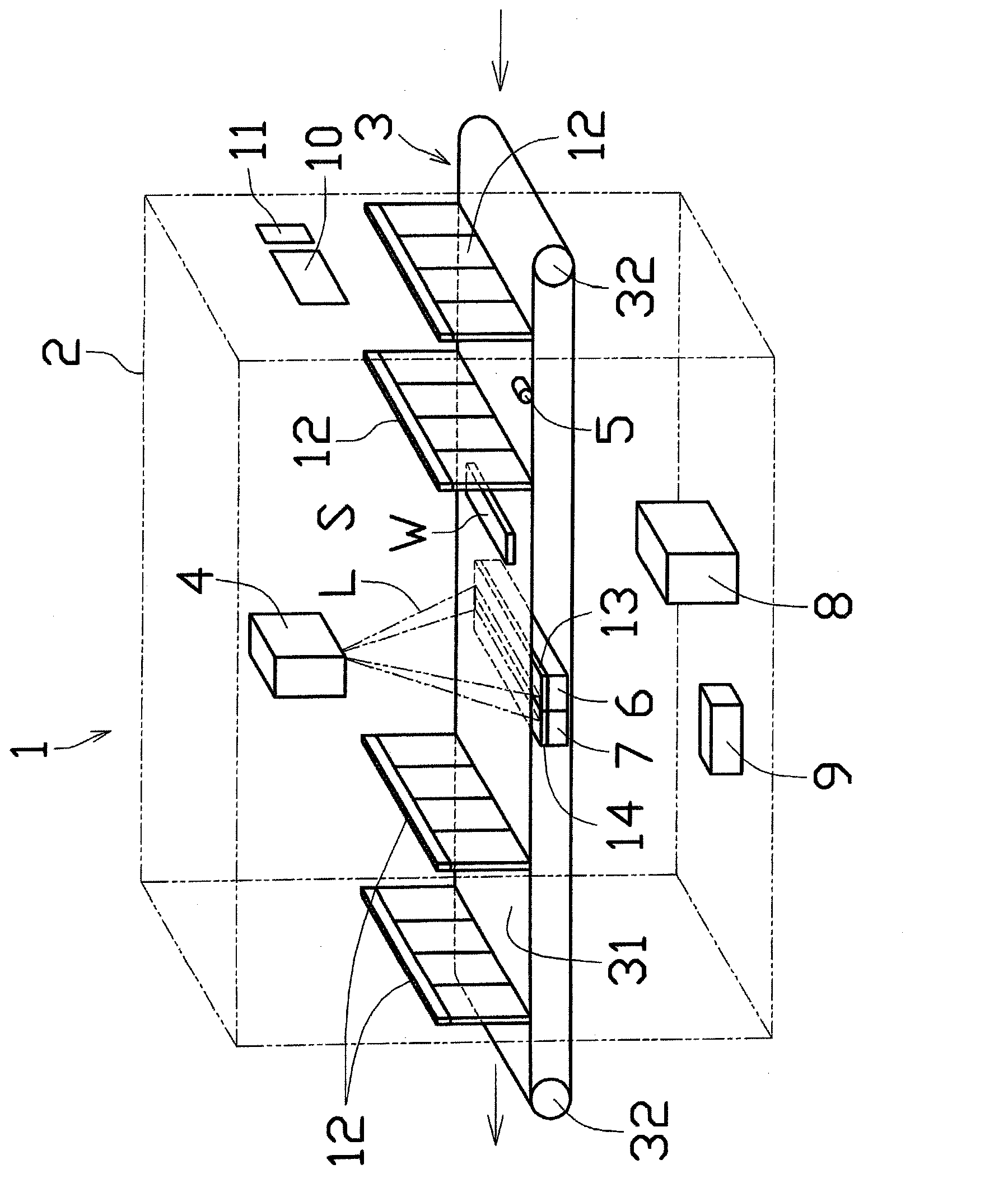

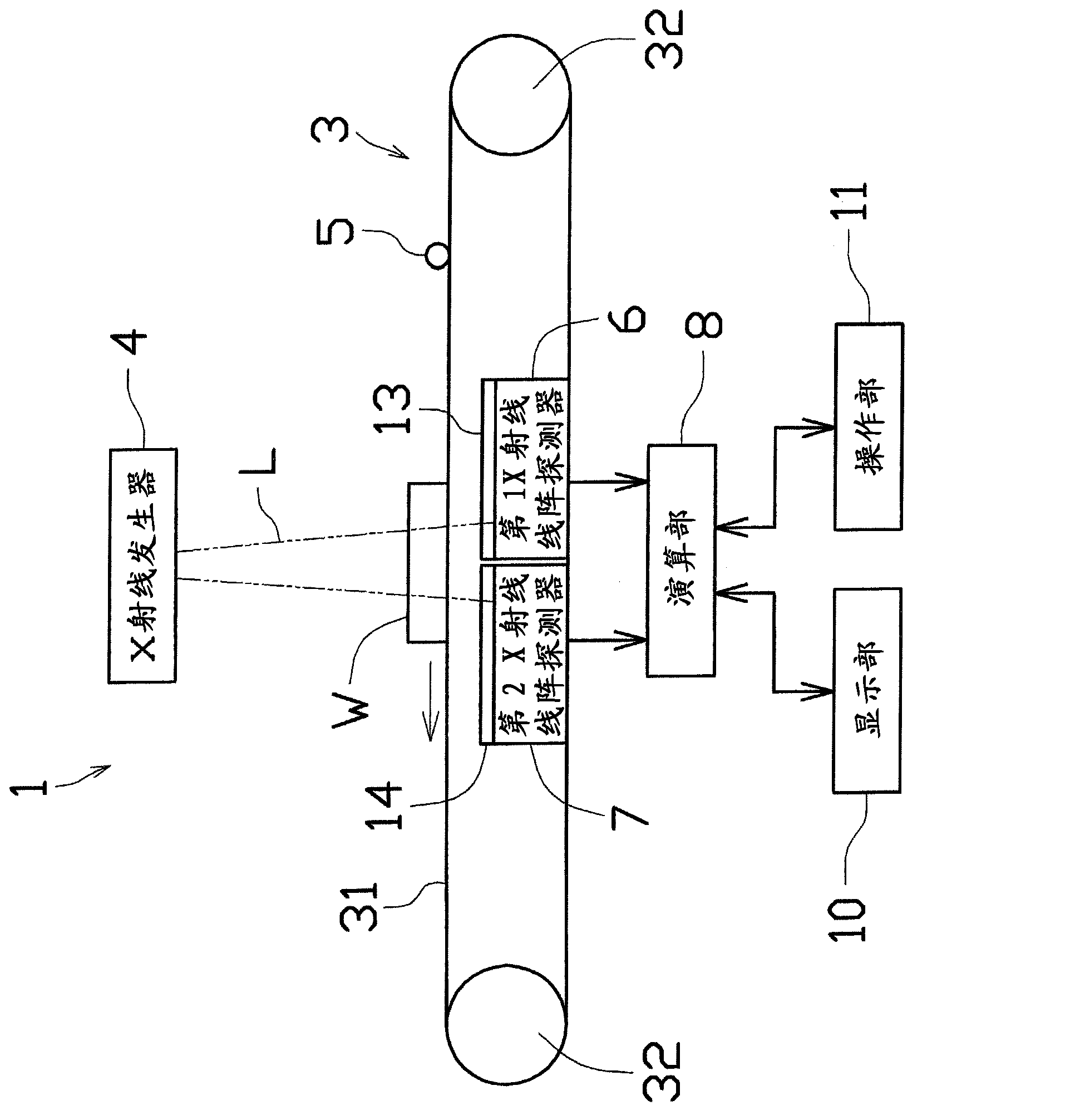

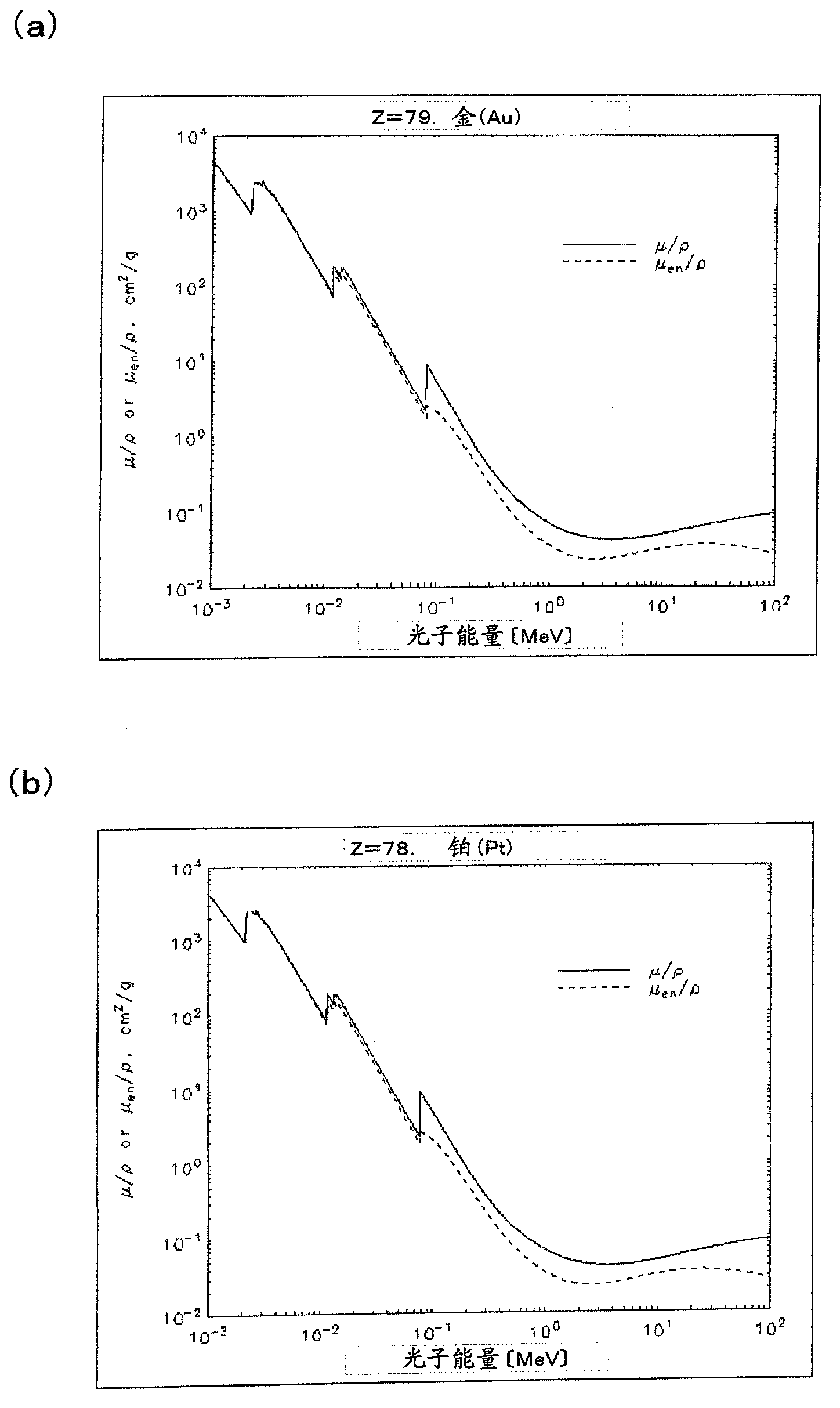

[0045] Next, an X-ray inspection apparatus 1 according to a first embodiment of the present invention will be described with reference to the drawings. The X-ray inspection device 1 of the present invention is as figure 1 As shown, it is equipped with: a transfer unit 3 for transferring the object W to be inspected in a box 2 for shielding X-rays; an X-ray generator 4 for irradiating X-rays to the object W being inspected during transfer; The inspection object W is moved to the optical height sensor 5 in the inspection space S in the box 2; the two X-ray line detectors 6 and 7 respectively detect the X-rays transmitted from the inspection object W; Calculator 8 for measuring the shape and content of gold (Au) contained in object W to be inspected based on the X-ray signals detected by X-ray line detectors 6 and 7; and power supply unit for supplying power to each part 9 etc. In addition, a display unit 10 for displaying measurement results obtained by the calculation unit 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com