Oil separator

A grease separation and grease technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as unsatisfactory water quality, low treatment efficiency, and large floor area. To achieve the effect of easy maintenance and cleaning, cleanliness and sanitation, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The embodiments of the present invention will be further described below in conjunction with the drawings and embodiments.

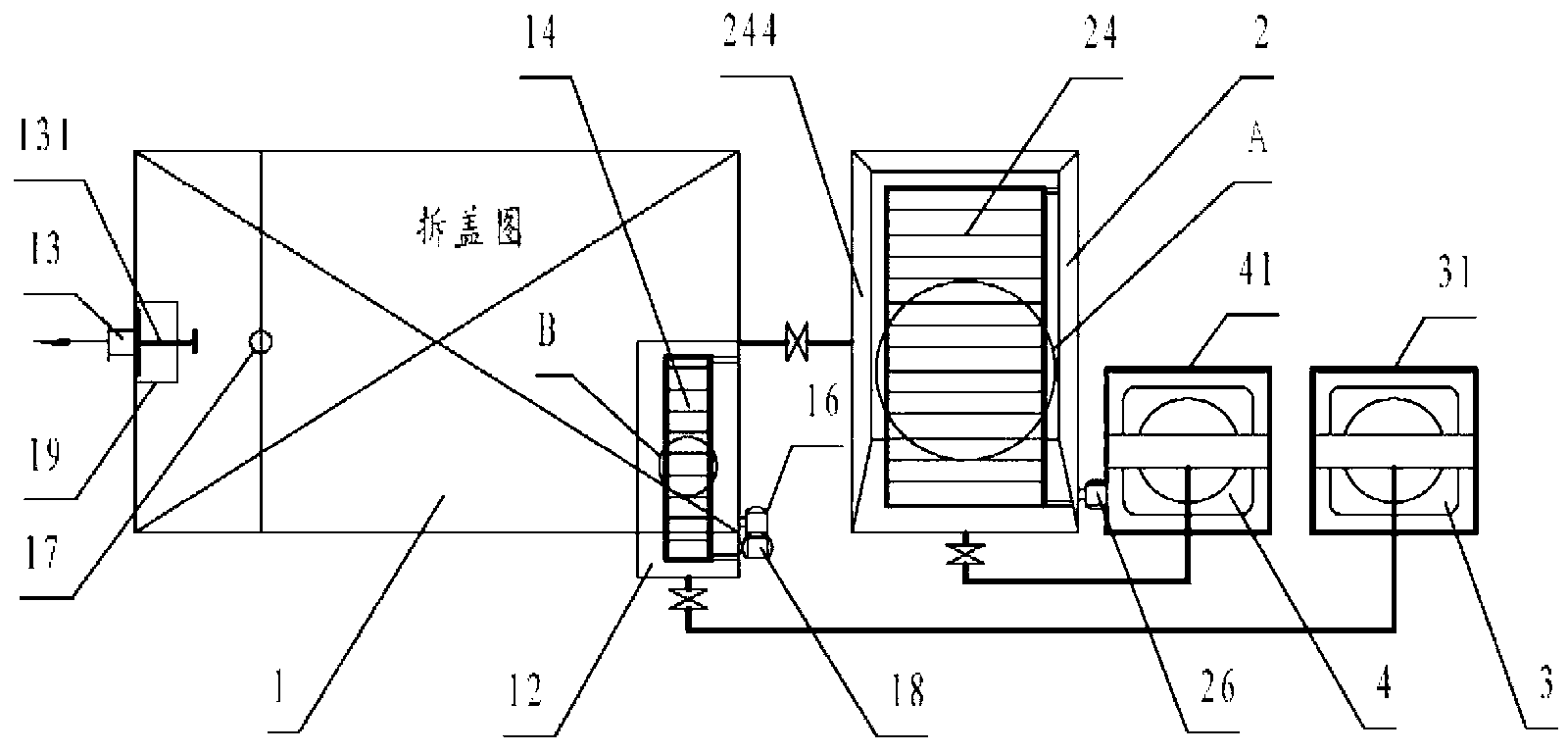

[0065] figure 1 is the main sectional view of the grease separator. figure 2 yes figure 1 Top view of the grease separator shown.

[0066] see figure 1 with figure 2 According to one embodiment of the present invention, the grease separator of the present invention includes a degreasing tank 1 and a deslagging tank 2 which is separately provided from the degreasing tank 1 .

[0067] The slag removal box 2 includes: a water inlet 21, which is arranged on the top of the slag removal box 2, or a water inlet pipe with a corresponding size, shape and orientation can be provided according to the different needs of users, and kitchen sewage is introduced into the slag removal box 2 through the water inlet 21. The liquid level S1 is formed in the slag removal box 2 and in the oil removal box 1 and the slag removal box 2; the slag discharge area 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com