Eddy Current Flaw Detector Pneumatic Automatic Ball Unloading System

An eddy current flaw detection, pneumatic technology, used in conveyor control devices, conveyor objects, conveyors, etc., can solve the problems of oil spots, falling on the ground, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

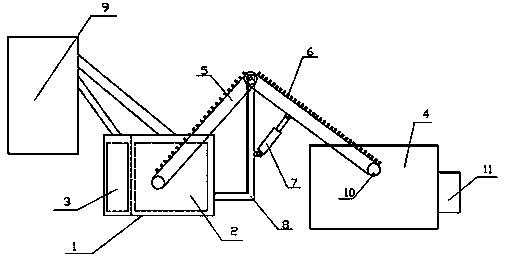

[0015] Such as figure 1 As shown, the pneumatic automatic ball unloading system of the eddy current flaw detector of the present invention includes an anti-rust oil tank 1, a plastic basket for qualified products 2, a plastic basket for unqualified products 3, a two-stage conveyor belt, a turnover box 4, a sensor 10 and a control box 11. The qualified product plastic basket 2 and the unqualified product plastic basket 3 are arranged in the anti-rust oil tank 1, and are respectively connected with the qualified product ball outlet and the unqualified product ball outlet of the flaw detector 9.

[0016] The two-stage conveyor belt consists of a fixed conveyor belt 5, an adjustable conveyor belt 6, a cylinder 7 and a bracket 8. Fixed conveyer belt 5 and adjustable conveyer belt 6 all are the oil-proof plastic type hoist conveyor device of band baffle. One end of the fixed conveyor belt 5 is set in the qualified product plastic basket 2, and the other end is fixed on the bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com