Full automatic counting stacker and stacking method thereof

A fully automatic, stacking machine technology, applied in packaging automatic control, packaging, packaging protection and other directions, can solve the problems of difficult to automate point packaging, packaging errors, wrong delivery to customers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

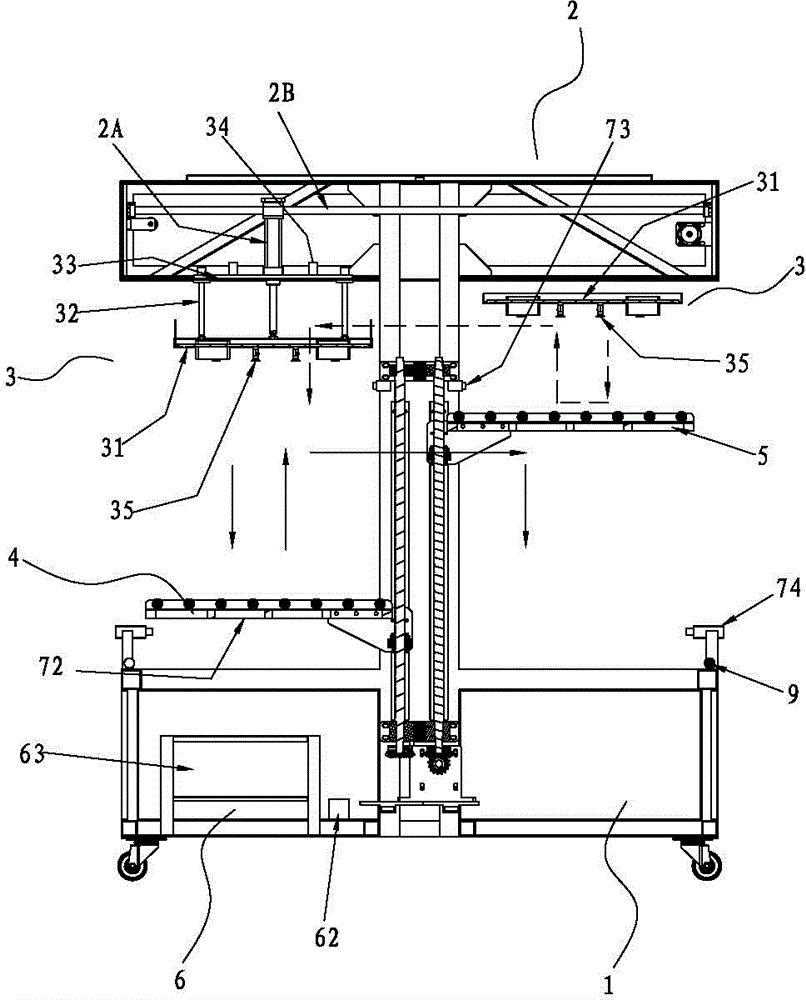

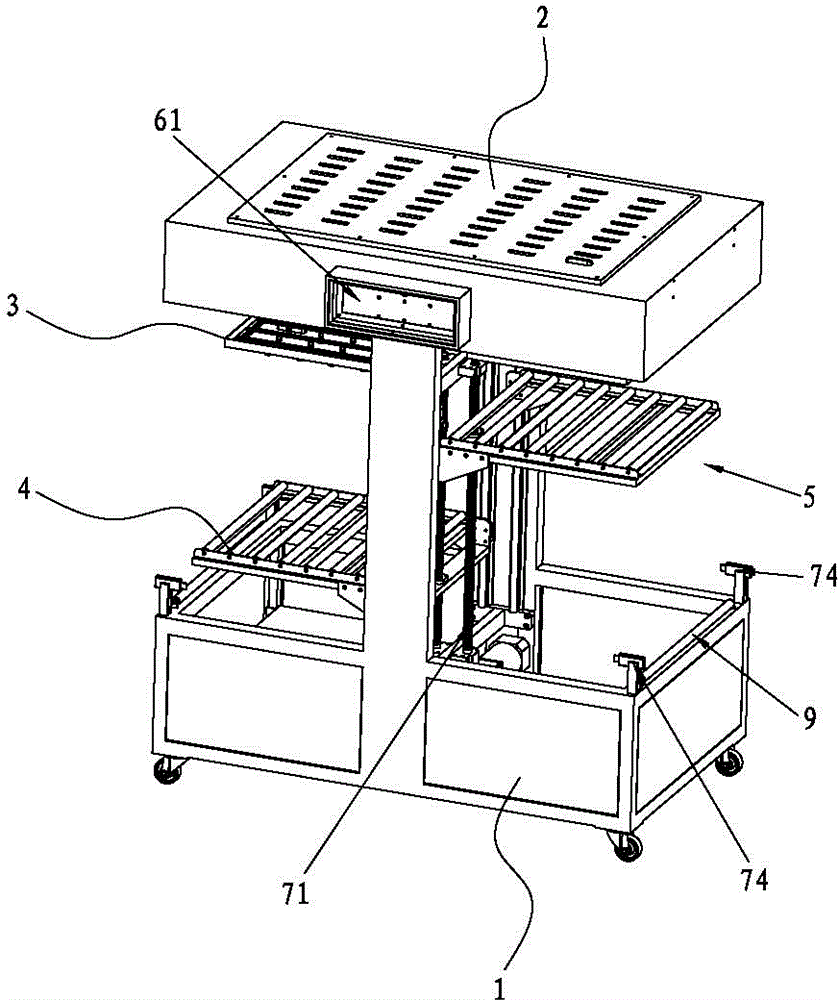

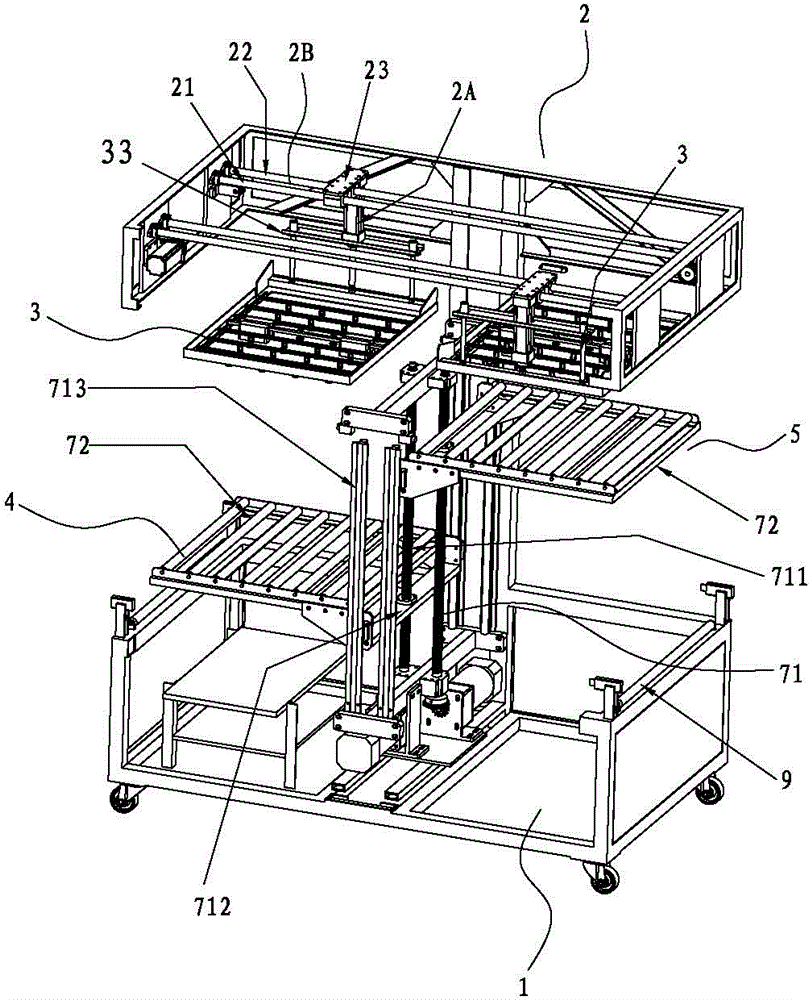

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

[0036] Such as figure 1 , figure 2 , image 3 As shown, a fully automatic counting and stacking machine, which includes a base 1;

[0037] At least one feeding module 2, the feeding module 2 is arranged on the top of the base 1, and the feeding module 2 is provided with a retrieving and stacking unit 3; a feeding module 2 includes two moving mechanisms with opposite moving directions of synchronous motion, each A reclaiming and stacking unit 3 is set on the first moving mechanism; in the initial state, one of the two moving mechanisms is located on the left side and the other is located on the right side;

[0038] At least one feeding module 4, the feeding module 4 is arranged on one side of the base 1, and cooperates with the feeding module 2;

[0039] At least one discharging module 5, the discharging module 5 is arranged on the other side of the base 1, and coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com