Device for preventing die core from corner collapse

A mold core, slump technology, applied in the field of injection mold processing, can solve problems such as increased cost, waste, appearance and size defects of plastic products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

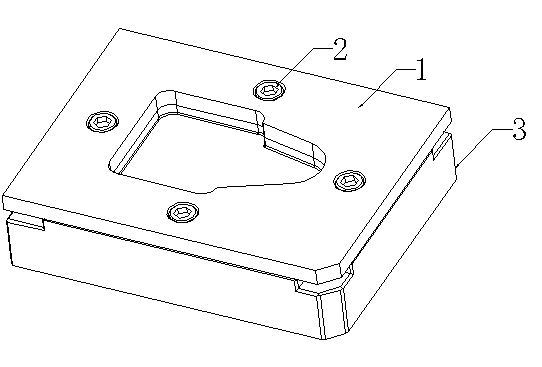

[0014] As shown in the figure, the device for preventing the mold core from collapsing includes the mold core 3, and also includes the jig plate 1 and the screw 2. The jig plate 1 is placed on the upper part of the mold core 3 for alignment, and the screw holes are distributed in the jig plate 1. , use screw 2 to fix it with mold core 3.

[0015] The dimensions of the fixture plate 1 are the same as those of the mold core 3 . The material of the fixture plate 1 is the same as that of the mold core 3 .

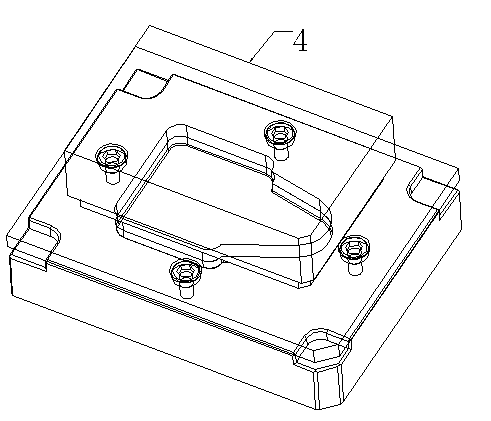

[0016] Fix the device on the workbench of the numerical control electric machining machine tool, and process it with the electrode 4 according to the normal electric machining process. on the mold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com