Upward ejection core rod with characteristic of easy replacement

A technology of ejector rod and rod body, applied in the direction of core, casting molding equipment, casting mold, etc., can solve the problems of increasing the workload of core repairing, reducing the efficiency of core making, easy to leak repair, etc., so as to control the rejection rate of castings, improve the The effect of core making efficiency and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

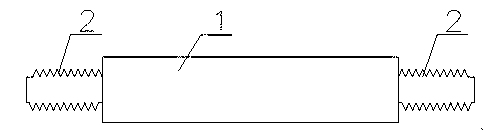

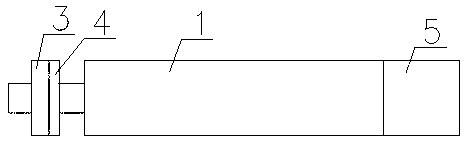

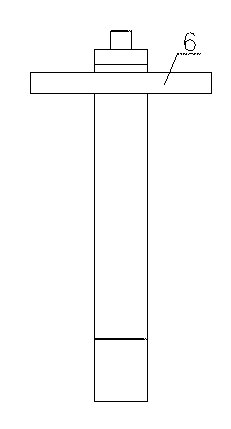

[0011] The specific embodiments of the present invention are given below according to the accompanying drawings, which are used to further describe the composition of the present invention in detail.

[0012] The upper mandrel that is easy to replace in this embodiment includes a rod body 1. External threads 2 are processed on both sides of the rod body 1. A nut 3 is threaded on the left end of the rod body 1. A spring washer 4 is arranged between the nut 3 and the rod body 1. A nylon rod 5 is threadedly connected to the right end of the rod body 1 .

[0013] Firstly, the iron upper core rod is made, and the two ends are processed with threads, which are respectively used to connect the upper core plate and the nylon rod, and the upper core rod is fastened on the upper core plate with a nut.

[0014] The upper mandrel that is easy to replace in this embodiment is that a nut and a nylon rod are added at both ends of the upper mandrel. The nylon rod is placed in a position that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com