Electrophoresis display particle comprising metal component and preparation method as well as functions thereof

A metal particle, electrophoretic display technology, applied in chemical instruments and methods, dyed polymer organic compound processing, optics, etc., can solve the problem of not being able to impart color to electro-optical displays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Example 1: Preparation of red electrophoretic display particles using gold nanoparticles

[0070] (1), get 1ml concentration and be 1% chloroauric acid solution, dilute with 80ml deionized water;

[0071] (2), get 4ml concentration and be 1% sodium citrate, add 80 microliters of tannic acid, then add 16ml deionized water to dilute;

[0072] (3), above-mentioned two kinds of solution water baths are heated to 60 degrees centigrade, then both are mixed, then transferred to 100 degrees centigrade oil baths and stirred for 10 minutes, made colloidal gold solution;

[0073] (4), centrifuge the solution in 3 steps, ultrasonically disperse the obtained gold nanoparticles in the ethanol solution of allyl thiol for 1-3 hours, and then mechanically stir for 2-10 hours;

[0074] (5), centrifuge to remove solvent, add ethanol to clean, centrifuge again, then add ethanol to clean and centrifuge;

[0075] (6), add toluene to wash and centrifuge twice;

[0076] (7), ultrasonicall...

Embodiment 2

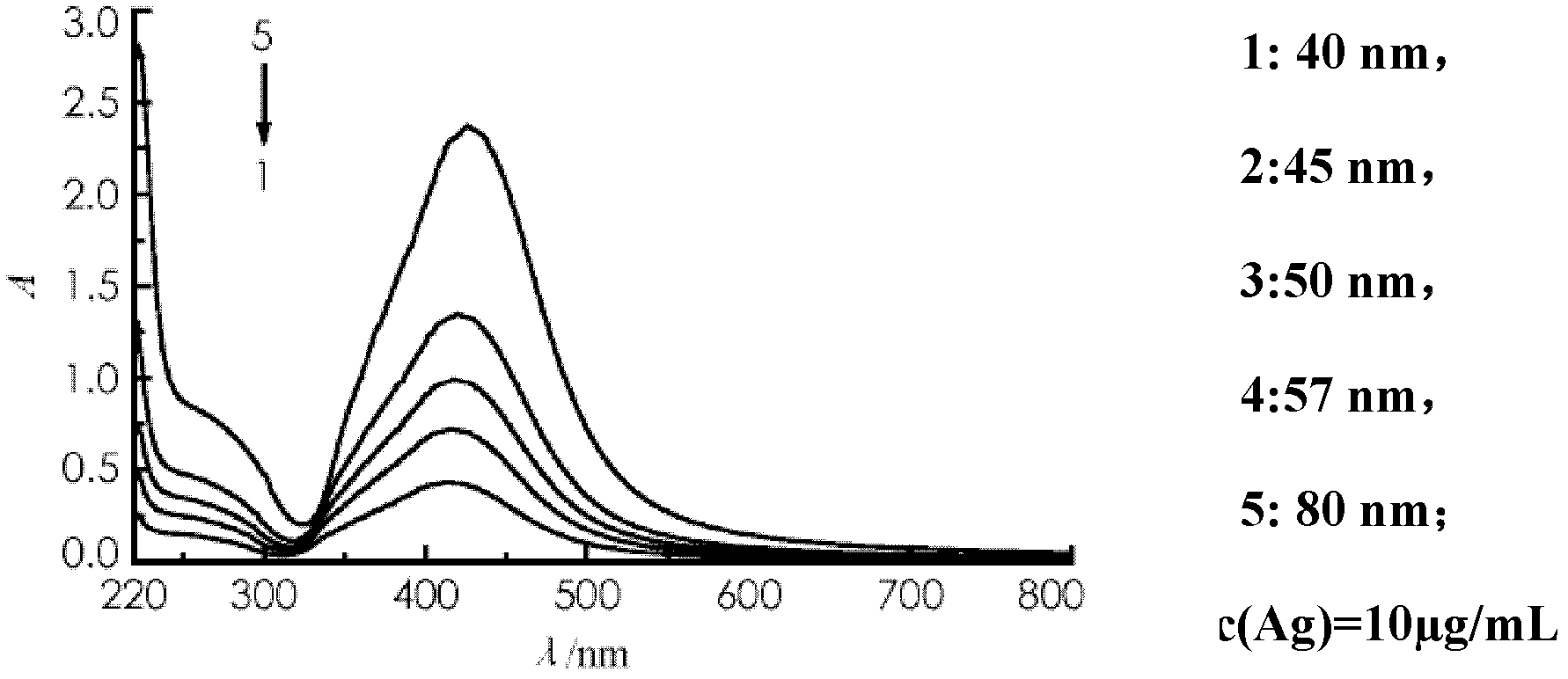

[0081] Example 2: Preparation of yellow electrophoretic display particles using SiO2 / Ag / SiO2 composite material

[0082] (1), 200 microliters of N-β (aminoethyl)-γ-aminopropyltrimethylsilane is dissolved in 20 milliliters of ethanol, then add a certain amount of commercial grade silica particles with a particle size of 100nm, stir 2 hours;

[0083] (2), centrifuge, and use methanol to clean and centrifuge twice, then disperse the solid in methanol;

[0084] (3), configuration concentration is the methanol solution of the silver nitrate of 0.0125mol / L, a certain amount of this solution is added the mixed liquor of step 2;

[0085] (4), place the mixture in a water bath at 30 degrees Celsius, add a small amount of formaldehyde dropwise, and stir for 1 hour;

[0086] (5), centrifugation, and respectively cleaning and centrifugation twice with water and methanol;

[0087] (6), the obtained solid is ultrasonically dispersed in methanol, and a certain amount of ethyl orthosilic...

Embodiment 3

[0092] Example 3: Preparation of yellow electrophoretic display particles using SiO2 / Ag / SiO2 composite material

[0093] Referring to the method of Example 2, the difference is that silicon dioxide is replaced by ferric oxide to prepare electrophoretic display particles of a composite material. The obtained particles have a particle size of about 50nm and bright color.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com