Cooling water recycling system for air compressor of air tower power generating station

A technology of cooling water circulation and air compressors, which is applied in the direction of machines/engines, mechanical equipment, liquid variable capacity machinery, etc., to achieve the effects of saving resources and energy, improving stability, and reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

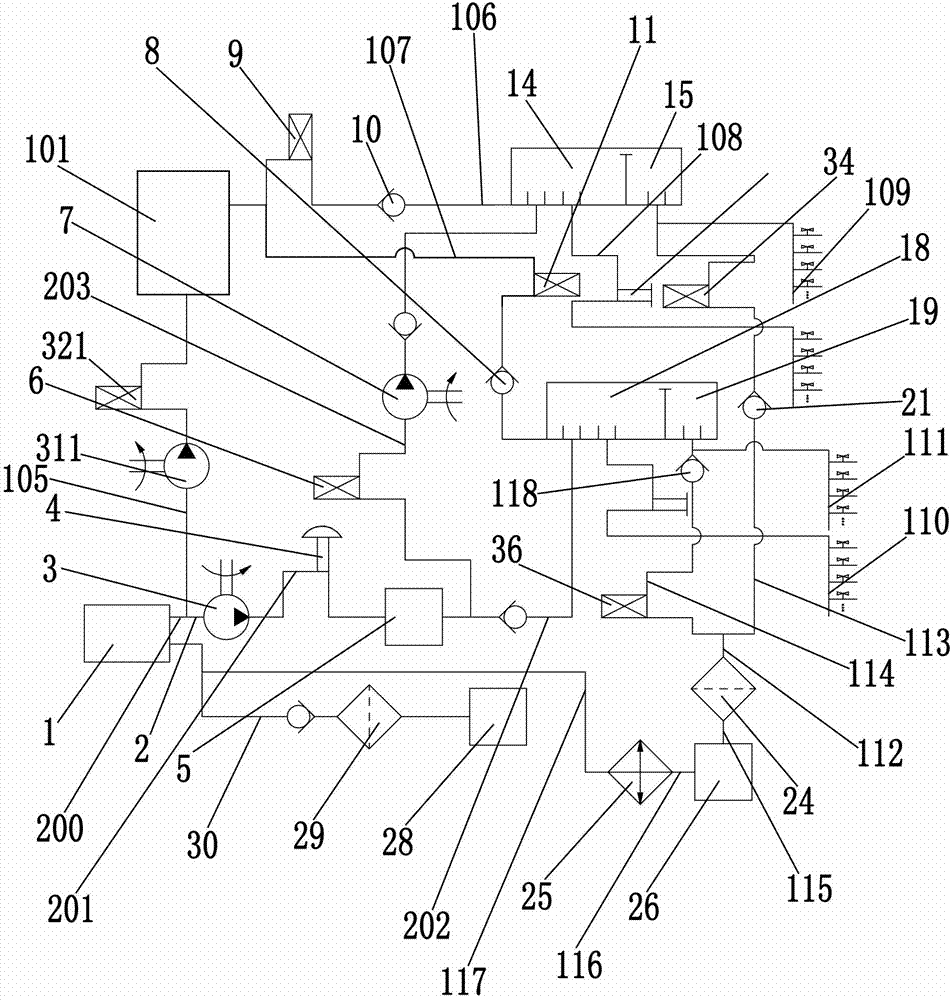

[0026] The specific embodiments of the present invention will be described in detail below with reference to the drawings.

[0027] Please see figure 1 , figure 1 It is a schematic diagram of a preferred embodiment of the air compressor cooling water recycling system for wind tower power stations according to the present invention. Such as figure 1 As shown, the air compressor cooling water recycling system of the wind tower power station includes an air compressor 1, an air compressor cold water input pipe 30, an air compressor hot water output pipe 2, a solar hot water system 101, a heat exchanger 5, and a high-rise building. Water tank, low-level water tank, high-level residential hot water pipe 108, high-level residential hot water pipe 109, low-level residential hot water pipe 110, low-level residential warm water pipe 111, recovery water pipe 112, filter 24, air duct well water circulation device 26 And cooler 25.

[0028] Such as figure 1 As shown, the high-level water tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com