Large two-stroke diesel engine with an exhaust gas purification system

A two-stroke internal combustion engine, large-scale technology, used in engine components, engine control, combustion engines, etc., can solve problems such as the inability to convert exhaust gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In the following detailed description, a crosshead type large turbocharged two-stroke diesel engine and a method for operating a crosshead type large turbocharged two-stroke diesel engine according to the present invention will be described through exemplary embodiments.

[0035] The structure and operation of large turbocharged two-stroke diesel engines of the crosshead type are well known and therefore require no further explanation herein. A detailed description regarding the operation of the exhaust gas purification system is provided below.

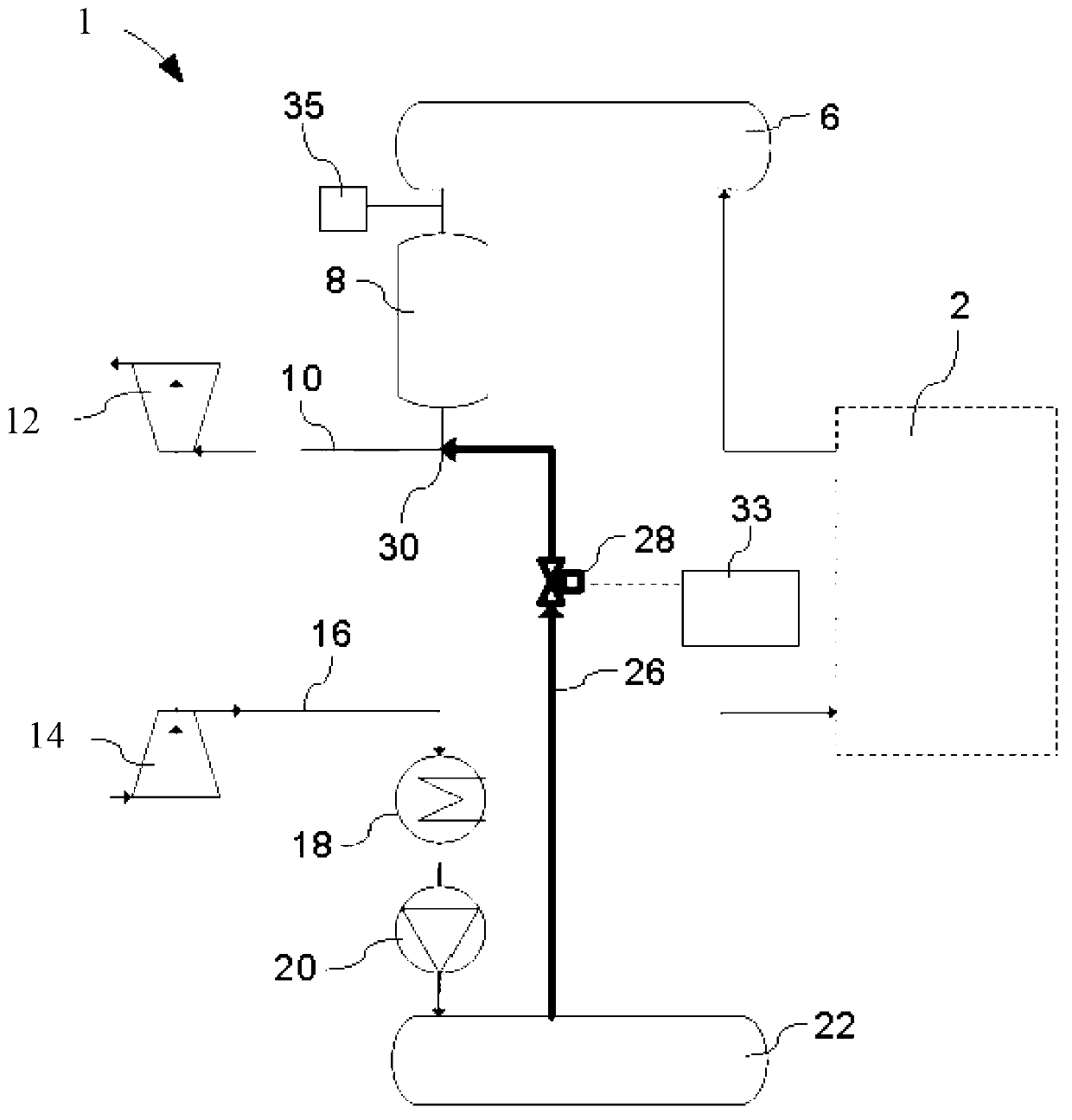

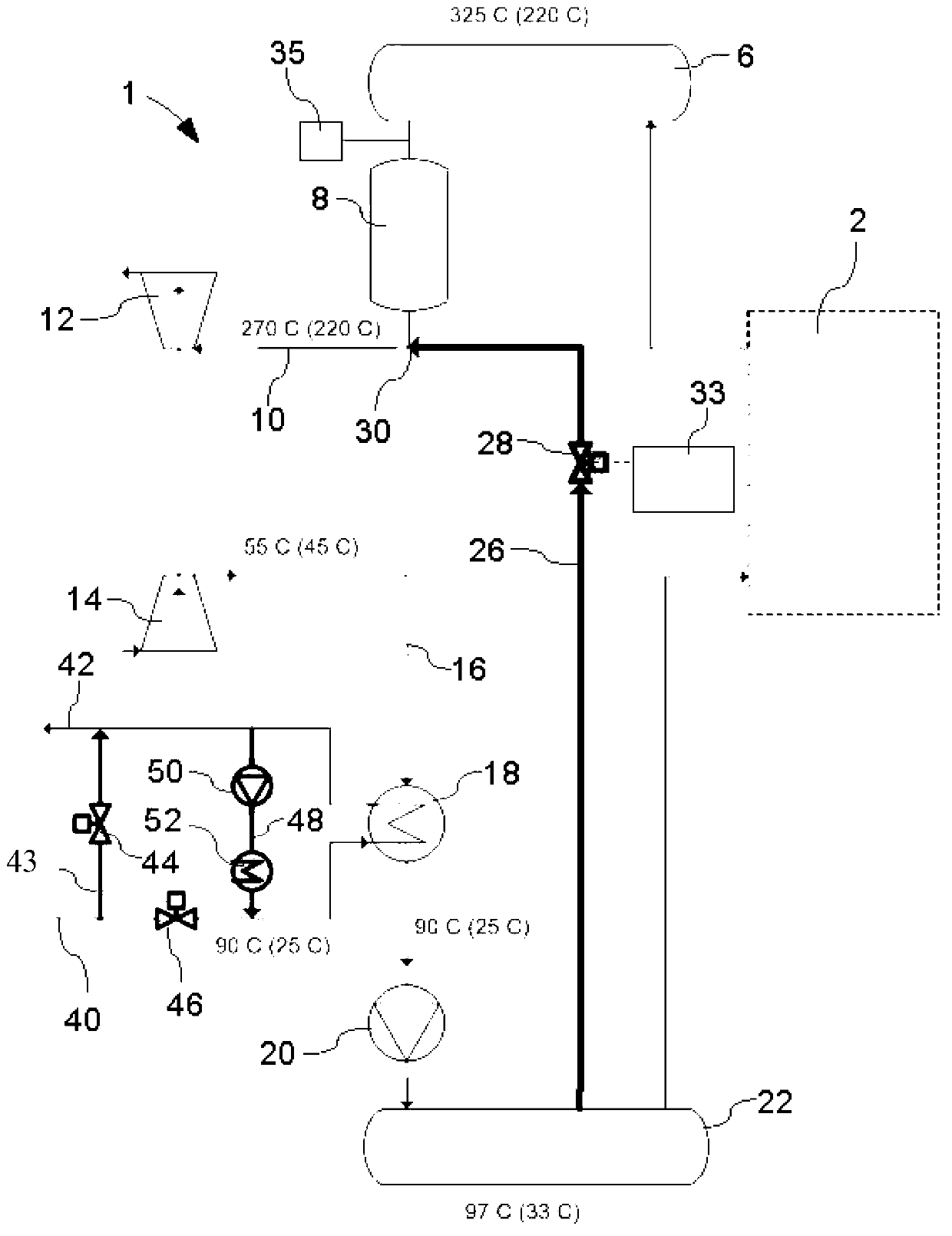

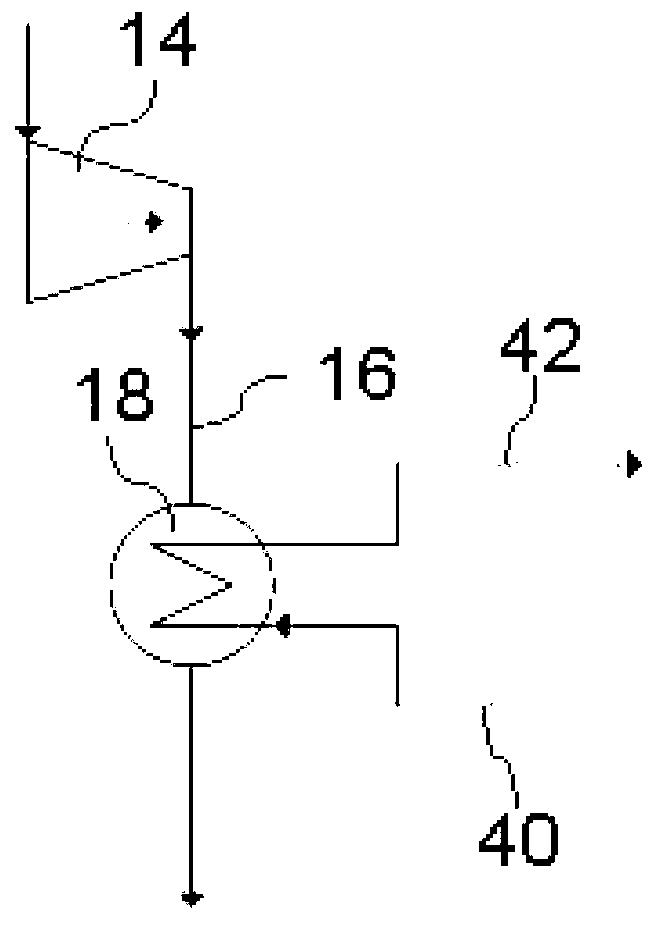

[0036] figure 1 A first exemplary embodiment of a large two-stroke diesel engine 1 according to the invention is shown. The engine 1 can be used, for example, as the main engine in an ocean-going vessel or as a stationary engine running a generator in a power station. The total output of the engine may for example be in the range of 5000 to 110000 kW.

[0037] The engine 1 is provided with a plurality of cylinders arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com