Method for preparing durable super-hydrophobic material

A super-hydrophobic and durable technology, applied in separation methods, chemical instruments and methods, metal material coating processes, etc., can solve the problems of loss of hydrophobic performance, high production cost, easy detachment of super-hydrophobic surface layer, etc., to achieve a wide range of applications , good durability, good performance in a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

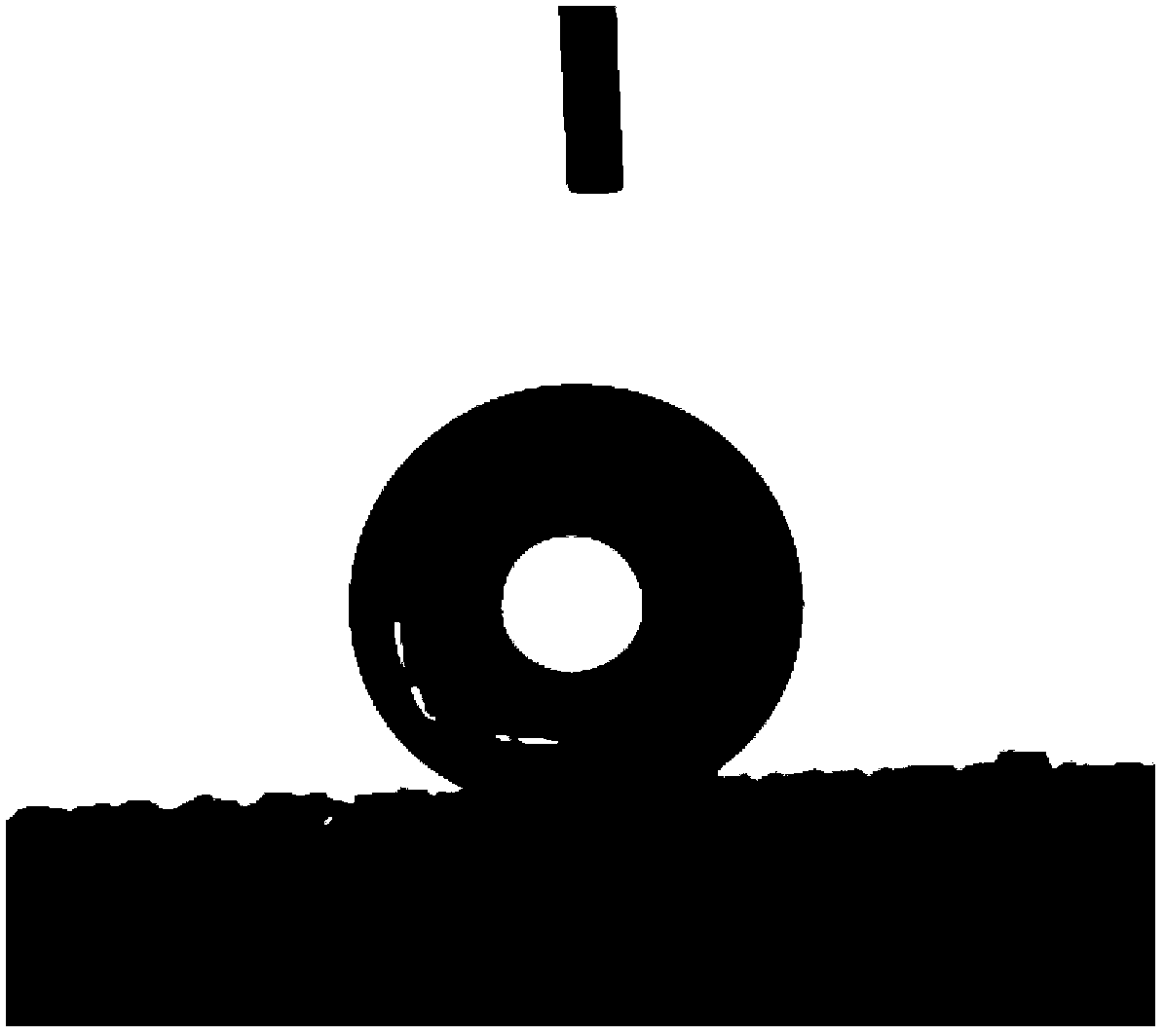

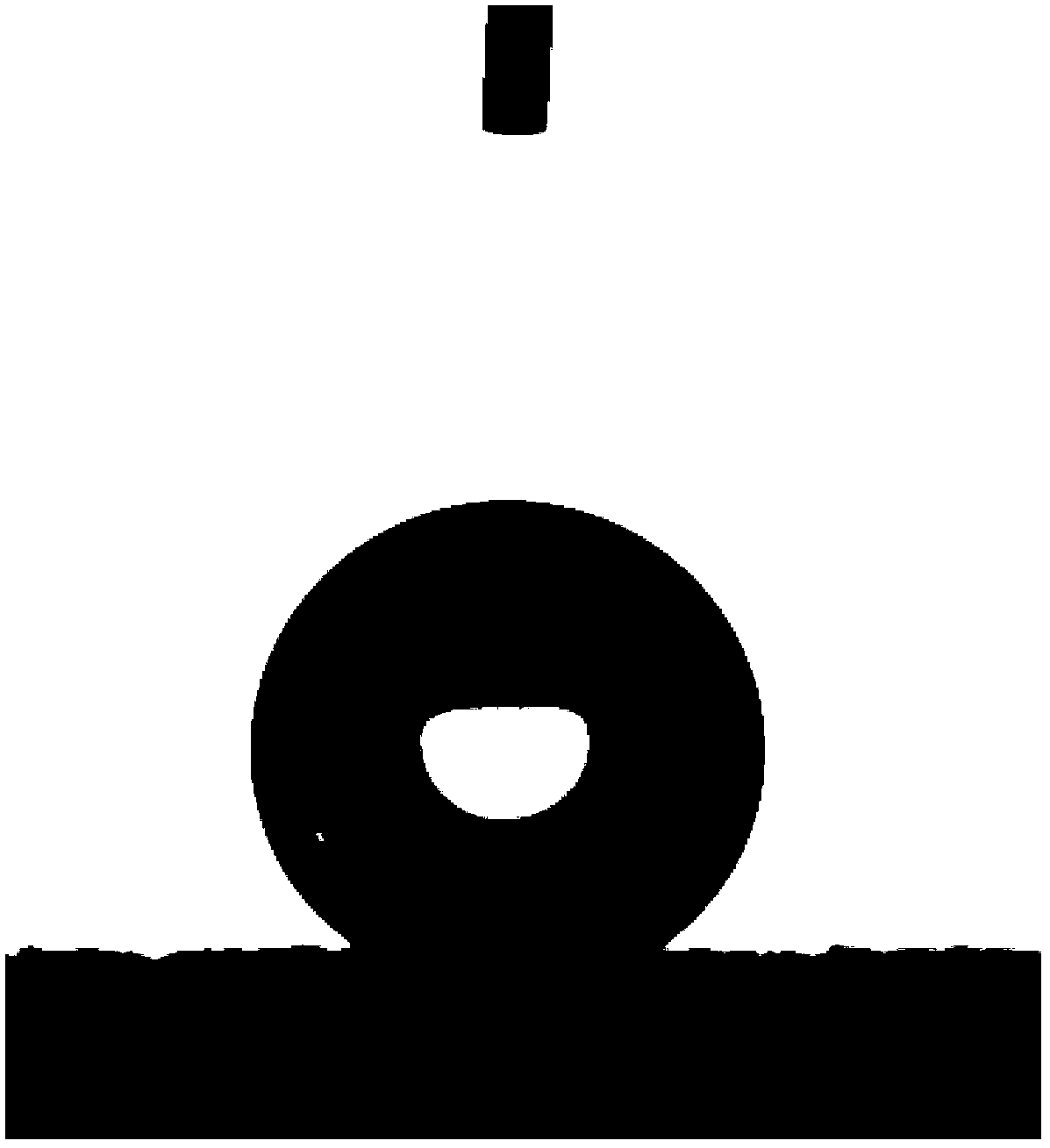

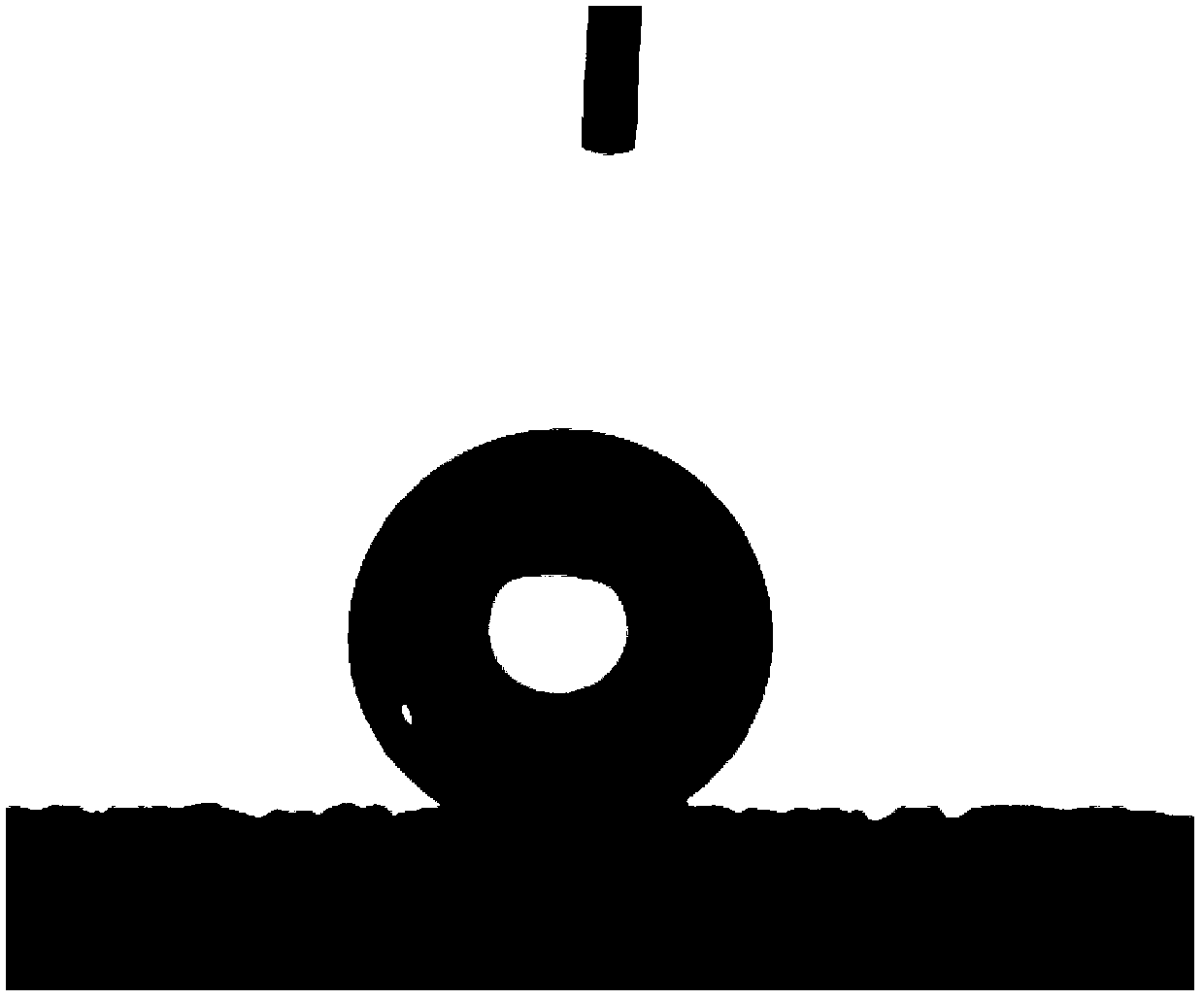

Image

Examples

specific Embodiment approach 1

[0010] Specific embodiment one: a kind of preparation method of durable superhydrophobic material of this embodiment is carried out according to the following steps:

[0011] 1. Preparation of nanoparticle dispersion: Ultrasonic disperse nanoparticles with a particle size of 10nm to 1000nm in water at a frequency of 24KHz to 40KHz to prepare a dispersion with a concentration of nanoparticles of 2mg / mL to 20mg / mL 2. Prepare the composite material of the matrix and nanoparticles: adjust the pH of the dispersion liquid of the nanoparticles prepared in step 1 with a concentration of 2 mg / mL to 20 mg / mL to be 1 to 6 with hydrochloric acid to obtain a mixed solution, and then place the matrix in Completely soak in the mixed solution, and then add dopamine to the above mixed solution that completely soaks the matrix to obtain the final mixed solution, and the concentration of dopamine in the final mixed solution is 0.5mg / mL~3mg / mL, and finally the speed is 100rpm~1000rpm Stir for 6h ...

specific Embodiment approach 2

[0016] Embodiment 2: This embodiment differs from Embodiment 1 in that the nanoparticles described in Step 1 are metal oxide nanoparticles or inorganic nanoparticles. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0017] Specific embodiment three: this embodiment is different from specific embodiment two in that: the metal oxide nanoparticles are ferric oxide nanoparticles or ferric oxide nanoparticles; the inorganic nanoparticles are silicon dioxide nanoparticles. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com