Clothes hanger conveying system

A conveying system and hanger technology, applied in the field of garment machinery, can solve the problems of affecting work efficiency, error, labor and effort, etc., and achieve the effect of simple structure, convenient use and perfect automation function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

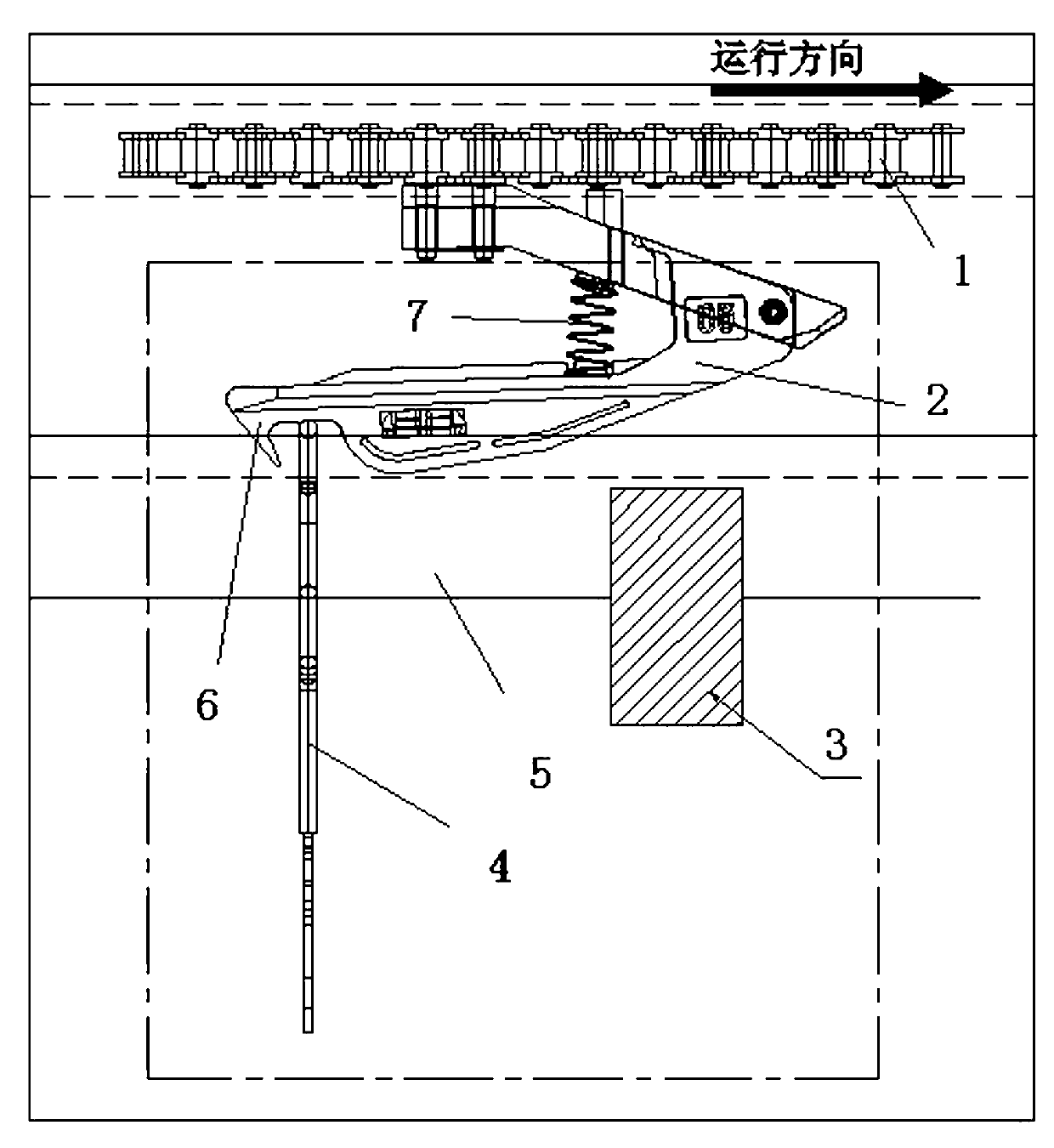

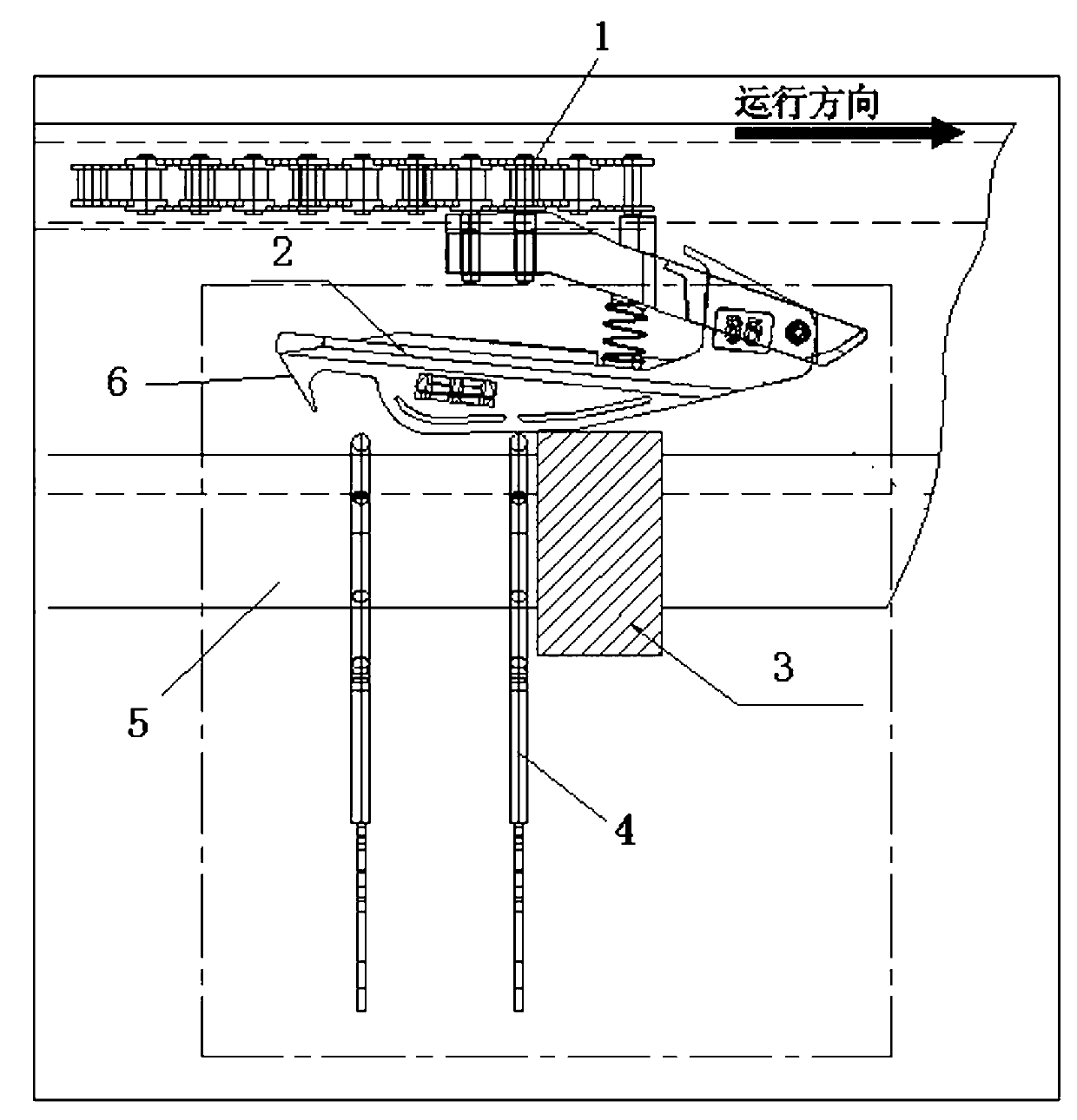

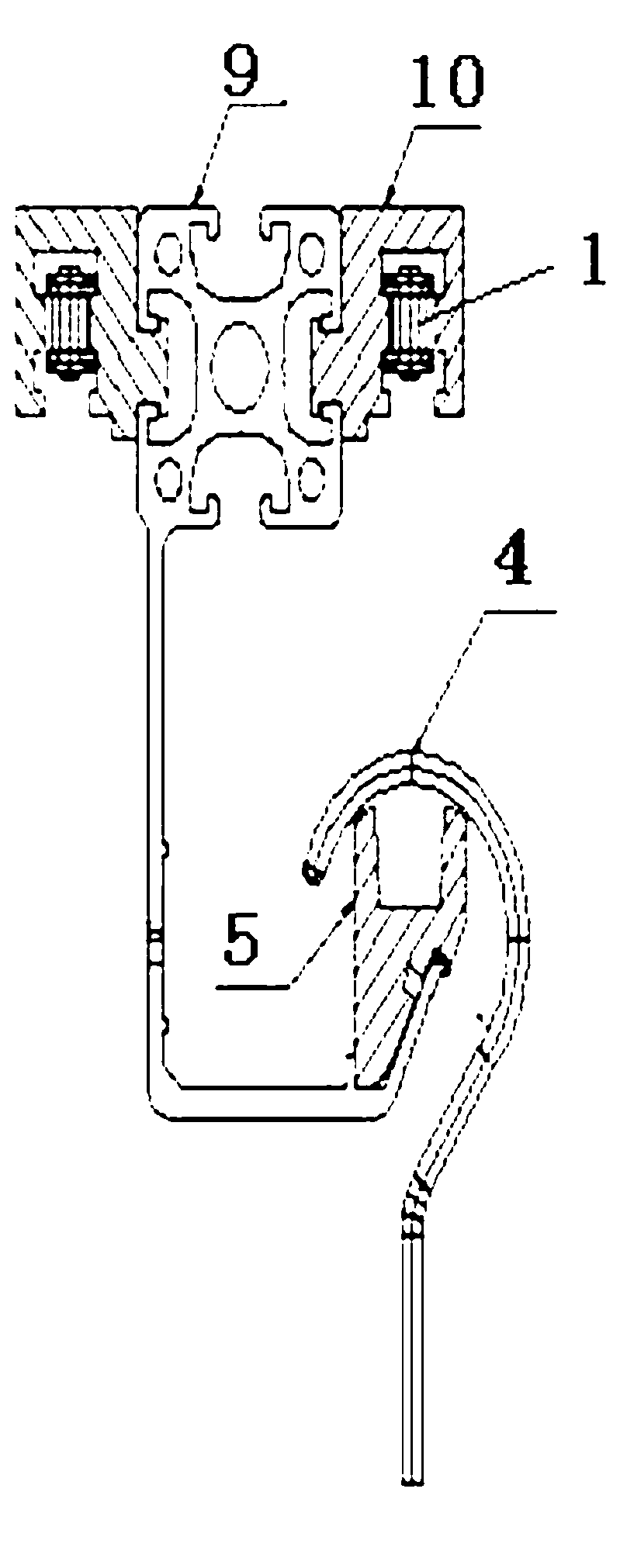

[0009] As shown in the figure, a hanger conveying system, including conveying chain 1, transport chain 1 below, is set with a hanger to transport skating 5, which is characterized by setting up a bird hook 2 on the top of the hanger transportation.The settings that are set with the settings with the bird hook 2 are set.There is a hanger to transport sliding 12 under the conveying chain 1, and the hooks of the hanger 11 are placed on the hanger transportation skating 5, such as figure 2 It is shown in the jelly rack transportation slide 12 to guide rail 9. The guide rail 9 is located within 10 guide slot 10, and the conveyor chain 1 is located within the guide slot 10 on both sides of the guide rail 9.The bird hook 2 is located directly above the groove.The bird hook 2 includes the upper component and the lower part of the component, which connects the upper component to the conveying chain 1, one end of the lower part of the lower component is rotated to the upper component, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com