Special wrench for removing anchor bits

A technology of anchor drill bits and wrenches, which is applied in the field of special wrenches, can solve the problems that the lower anchor drill bits cannot be unloaded, and achieve the effects of reducing production costs and resource consumption, convenient operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

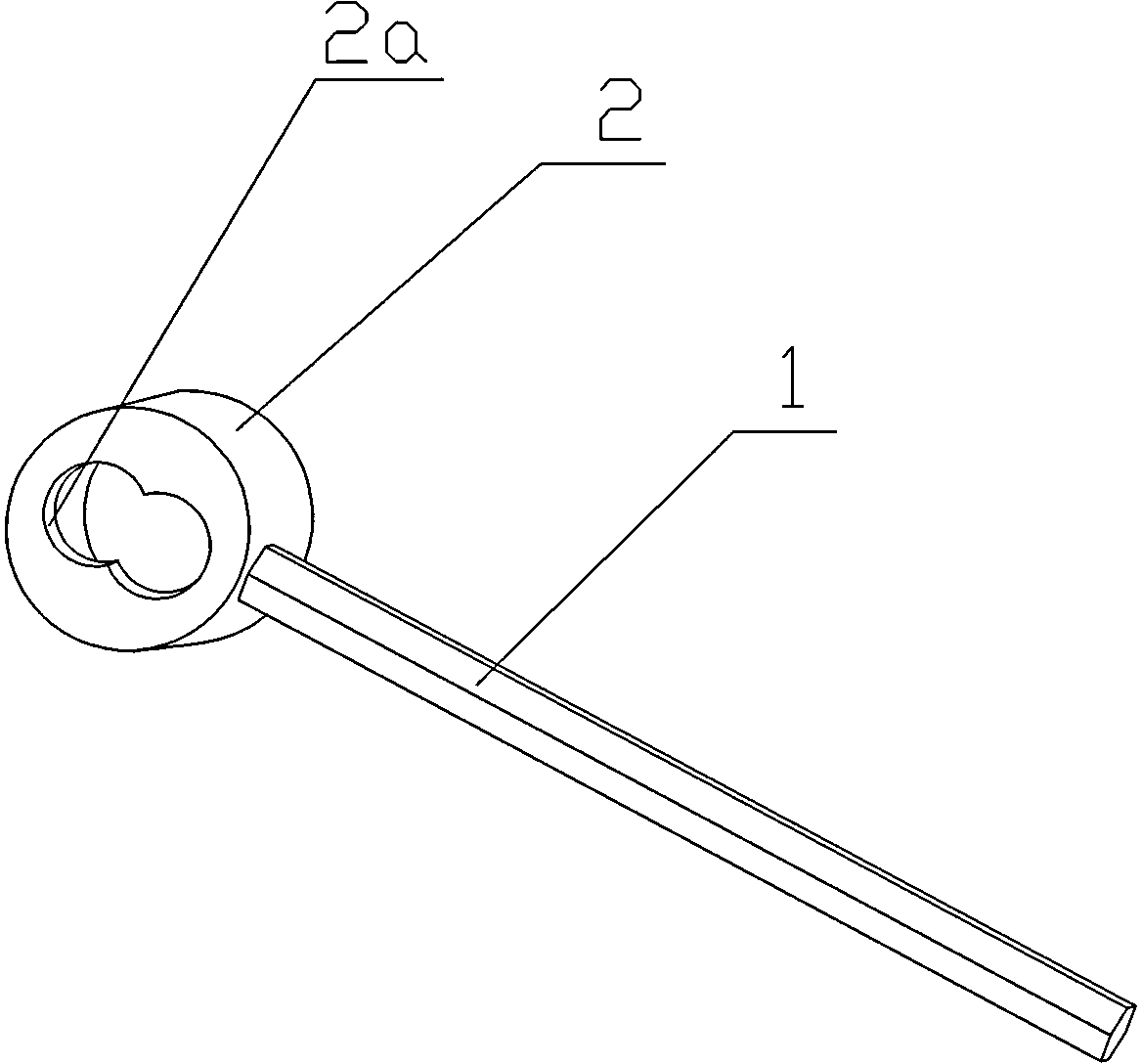

[0014] Such as figure 1 As shown, the present invention provides a special wrench for dismounting the anchor drill bit, comprising a hexagonal handle 1, one end of the hexagonal handle is connected with a sleeve 2, the sleeve 2 is welded to the handle, and one end of the sleeve is provided with a The suitable "8" shaped hole 2a of the anchor drill bit is clamped and fitted with the left wing seat and the right wing seat of the anchor drill bit by the "8" shaped hole 2a.

Embodiment 2

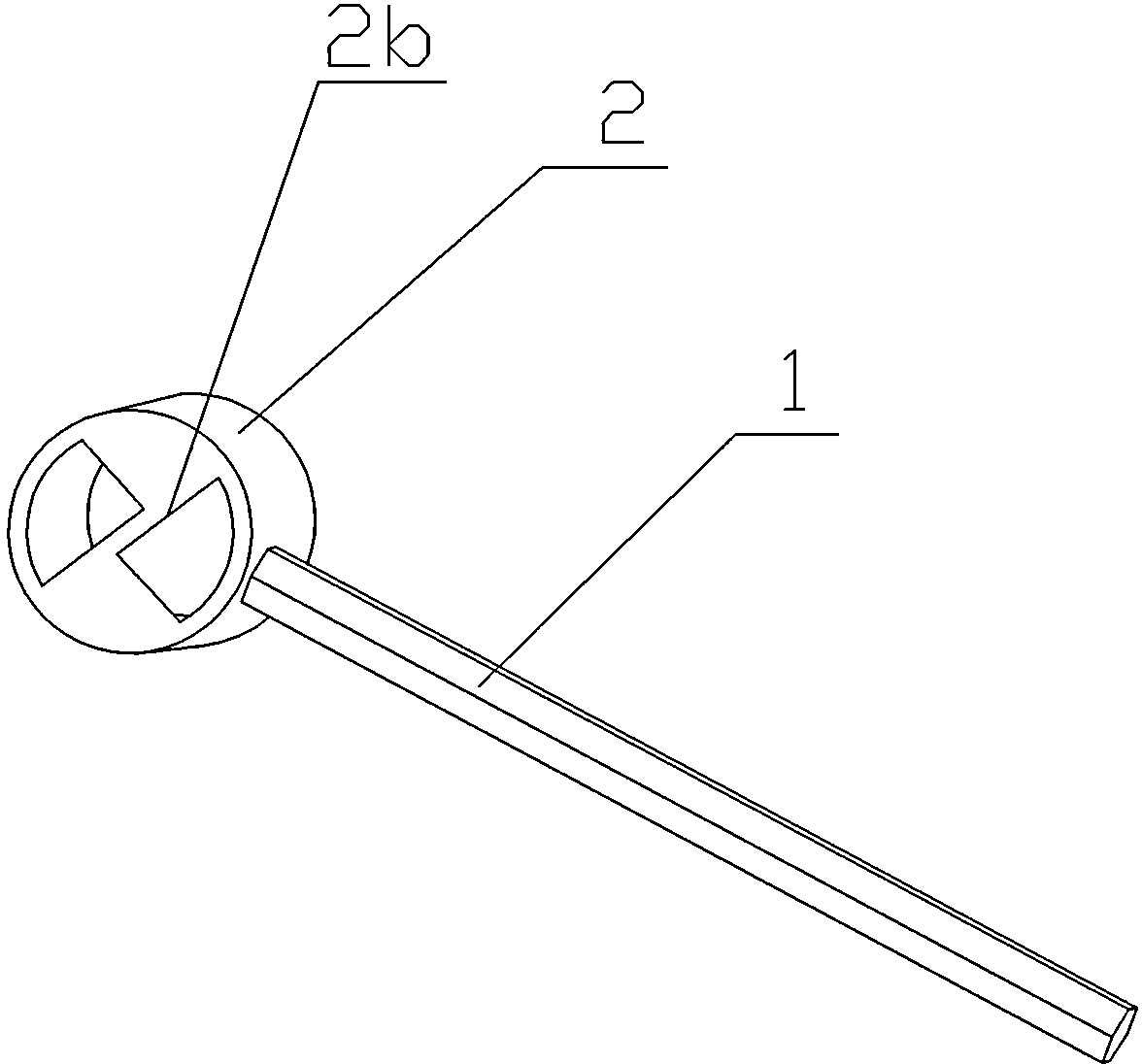

[0016] Such as figure 2 As shown, the present invention provides a special wrench for dismounting the anchor drill bit, comprising a hexagonal handle 1, one end of the hexagonal handle is connected with a sleeve 2, the sleeve 2 is welded to the handle, and one end of the sleeve is provided with a A pair of fan-shaped holes 2b with proper shape of the rock-bolt drill bit are clamped and fitted respectively with the left-wing seat and the right-wing seat of the rock-bolt drill bit through the two fan-shaped holes 2b.

[0017] use operation

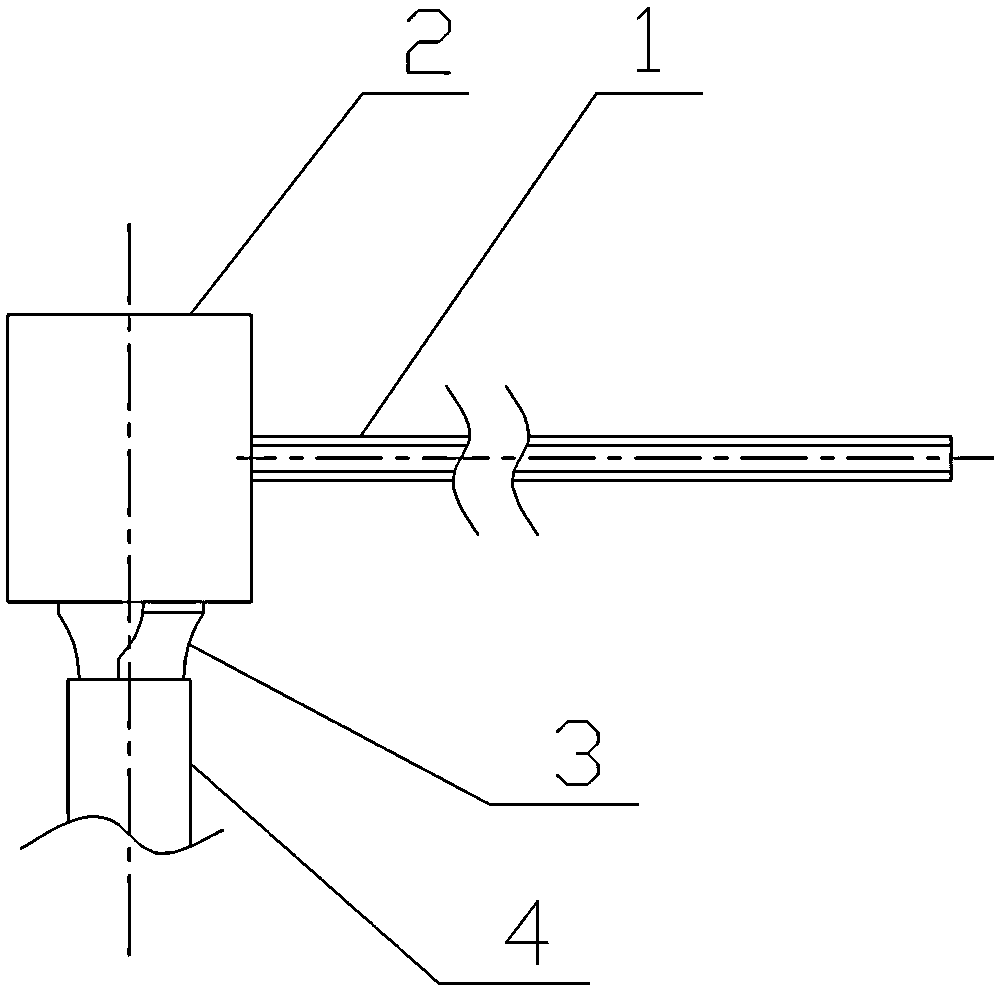

[0018] Such as image 3 As shown, after the clamp on the working platform clamps the drill bit connecting sleeve 4, the left wing seat and the right wing seat of the damaged anchor drill bit 3 connected to the drill bit connecting sleeve are clamped through the clamping hole of the sleeve, and then rotated The handle 1 drives the sleeve 2 to unload the damaged anchor drill bit 3, and leaves the reusable drill bit connecting sleeve 4, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com