Air treating system with in-situ recycling function

An air treatment system and in-situ technology, applied in the field of air environment purification, can solve the problems of one-time waste of filter materials, failure to recover particulate matter and gaseous substances, etc., and achieve the effect of excellent purification efficiency, high degree of automation, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

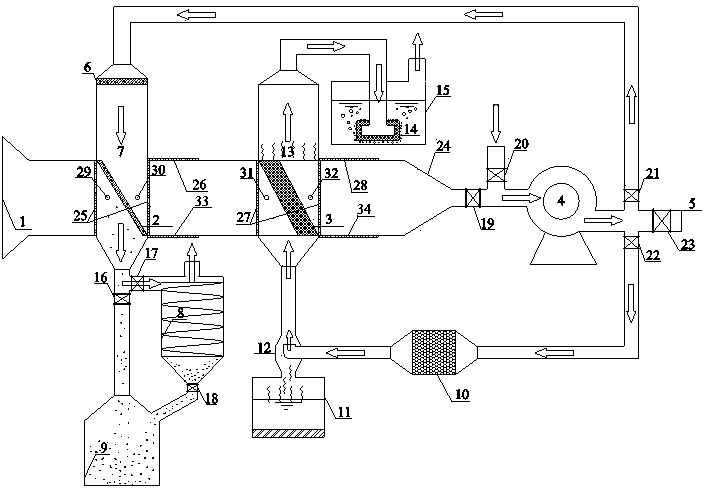

[0026] Example 1: figure 1As shown, an air treatment system with in-situ recovery function is characterized in that the system is composed of air filtration system I and in-situ recovery and regeneration system II; Filter layer 2, activated carbon adsorption layer 3, fan 4 and purified gas outlet 5; in-situ recovery and regeneration system II consists of dust filter layer recovery and regeneration system II-1 and activated carbon adsorption layer recovery and regeneration system II-2. The dust filter layer recovery and regeneration system II-1 includes a high-efficiency filter layer 6, a first gate system 7, a cyclone dust collector 8 and a dust storage bin 9, and the first gate system 7 includes two first vertical gates 25, a first horizontal Gate 26 and a third horizontal gate 33; activated carbon adsorption recovery regeneration system II-2 includes filter adsorption layer 10, desorbent heating system 11, air flow mixer 12, second gate system 13, gas diffuser 14 and vapor a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com