Preservation cabinet

A technology of fresh-keeping cabinets and capillary materials, applied in cabinets, home appliances, applications, etc., can solve the problems of poor fresh-keeping effect of non-power consumption fresh-keeping devices, and achieve the improvement of fresh-keeping effect, water evaporation efficiency, and humidity in the cabinet. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

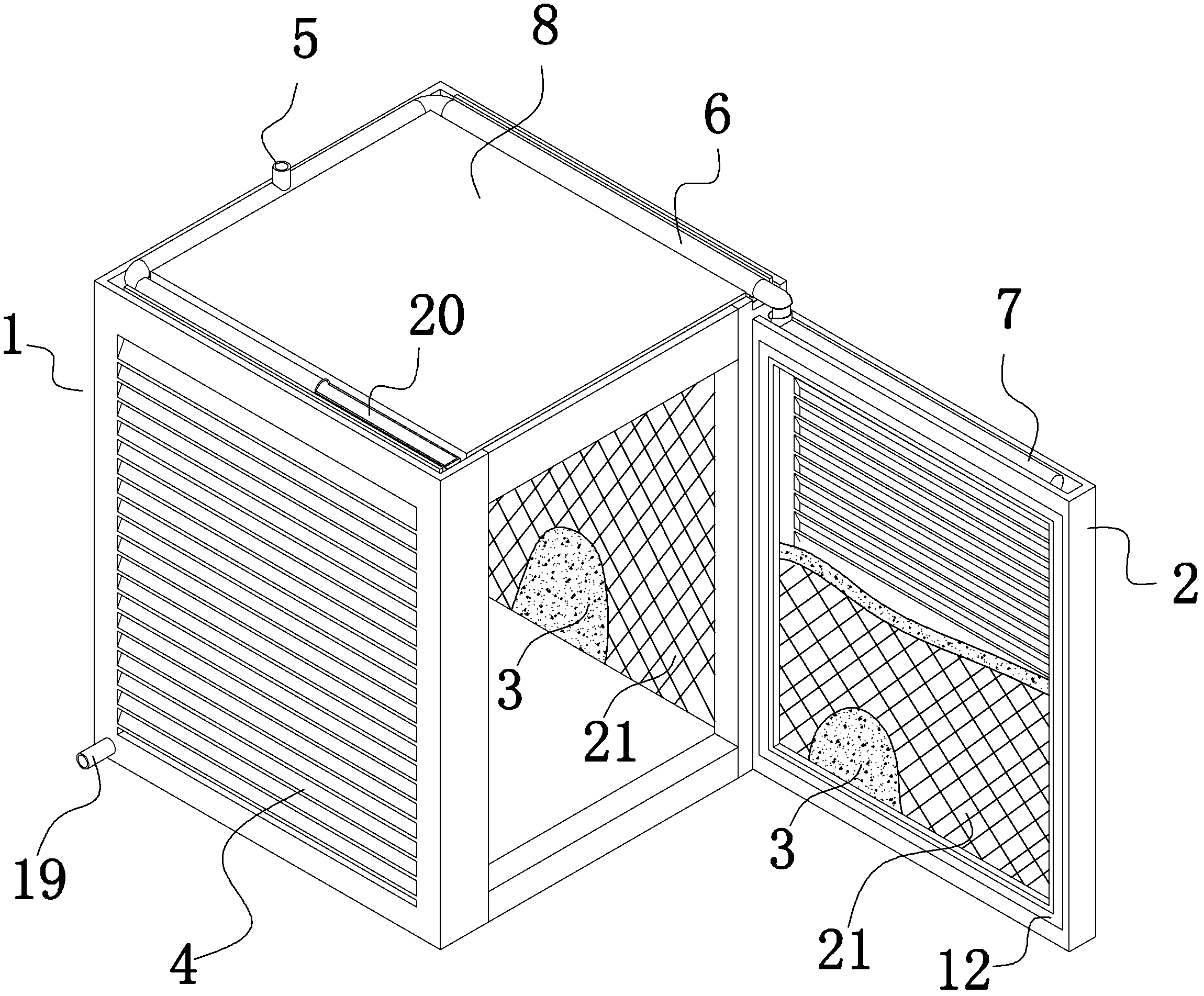

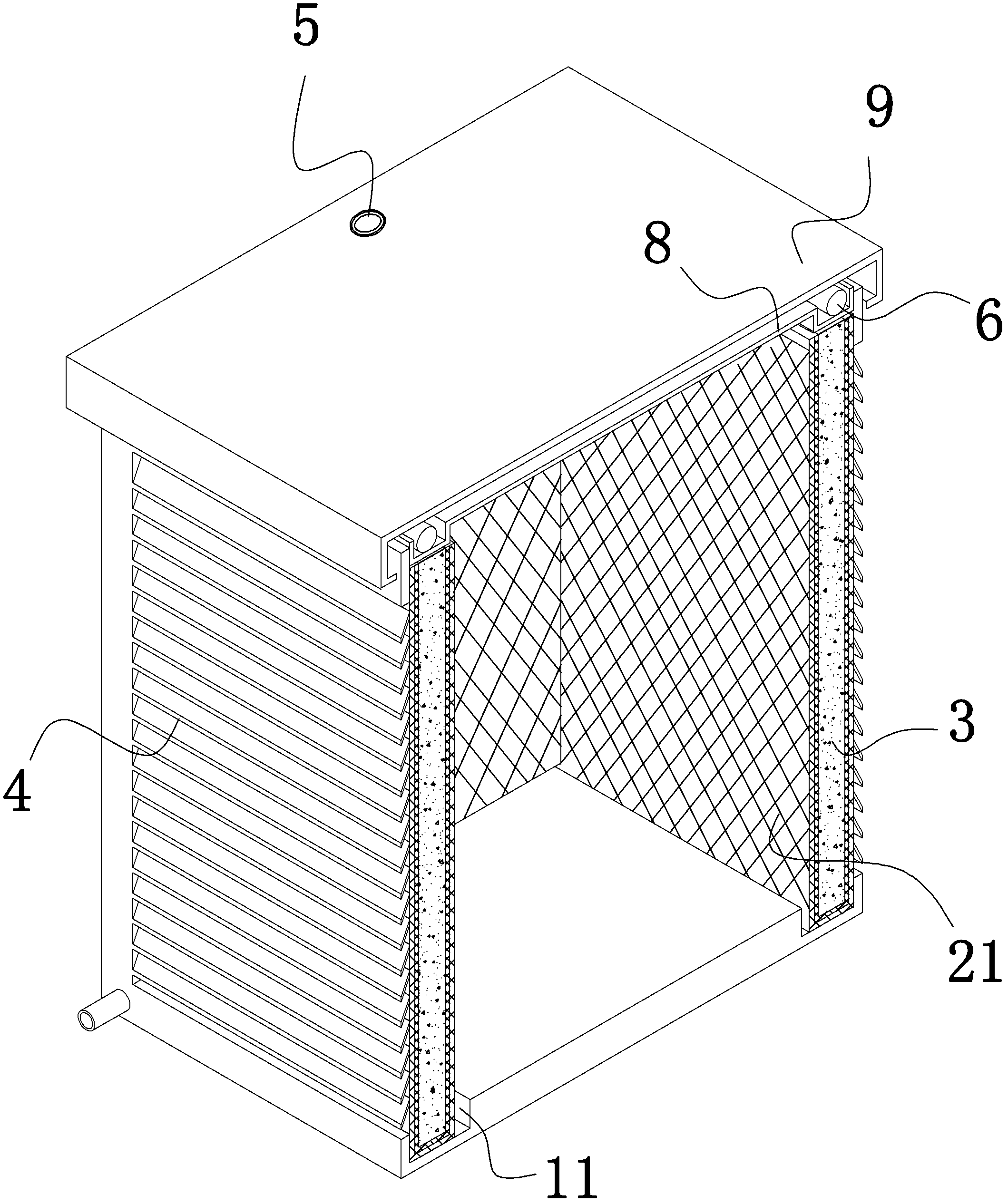

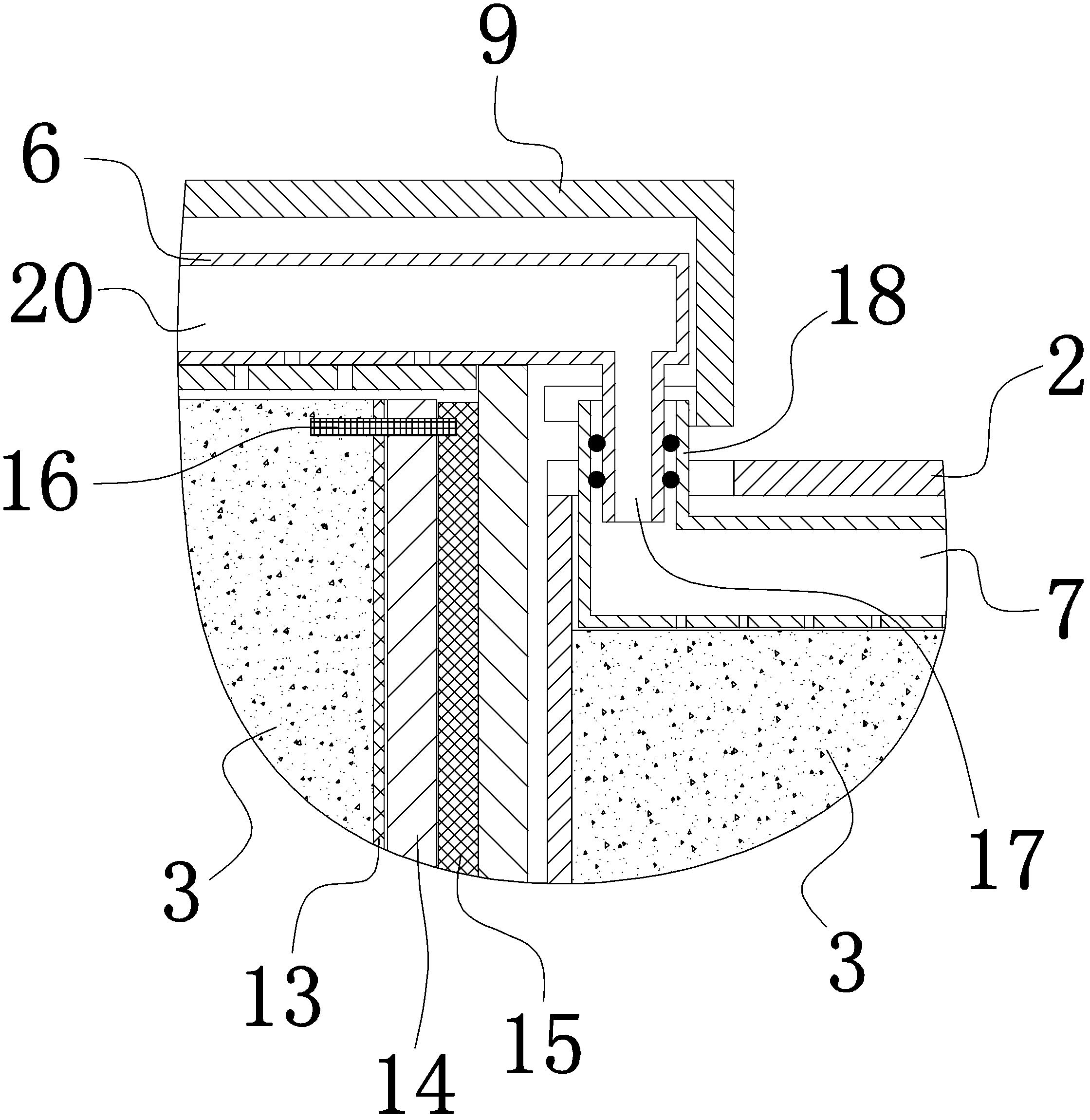

[0024] Example 1, such as figure 1 , figure 2 As shown, a fresh-keeping cabinet includes a cabinet body 1 and a side door 2 hinged on the cabinet body 1 . Ventilation holes are arranged on the outer surface of the fresh-keeping cabinet, and the ventilation structure of the ventilation holes can also be replaced by a louver ventilation structure 4 . A capillary material layer 3 extends from the bottom surface of the fresh-keeping cabinet to the top surface and is arranged on the side wall of the storage space of the fresh-keeping cabinet. The capillary material layer is mainly considered from the structure, and is not limited to one material, as long as the sum of the void surface area of the capillary material layer is greater than the surface area of the capillary material layer, the porosity of the capillary material layer is between 20% and 50%; at the same time, it has good A hydrophilic capillary material is sufficient. The capillary material layer can be made of ...

Embodiment 2

[0034] Embodiment 2, the capillary material layer is made of hemp bark that is ground into granules, or reed that is ground into granules, or wheat straw that is ground into granules, or bark that is ground into granules, or ground into granules. The combination of burlap bark and reed in granular form, or the composition of bark husk, reed, bark and wheat straw crushed into granular form is produced by pressing. The porosity of the capillary material layer is 20% to 50%. Refer to Embodiment 1 for the rest of the structure in this embodiment.

[0035] The material of the capillary material layer in Example 2 is natural fiber, which has better hydrophilicity than artificial fiber. Importantly, the capillary material in this scheme is crushed into granules, the capillaries in the material fibers are cut and arranged in a disordered manner. Since the capillary in the capillary material fiber is cut off, water can be better absorbed in the capillary material layer without flowin...

Embodiment 3

[0036] Example 3, such as Figure 5 As shown, the capillary material layer 3 is composed of an inner capillary material layer 32 and an outer capillary material layer 31 . The porosity of the inner capillary material layer 32 is 20% to 30%; the porosity of the outer capillary material layer 31 is 50% to 80%. The inner capillary material layer is in contact with the storage space of the fresh-keeping cabinet, and the outer capillary material layer is in contact with the external space; the thickness of the inner capillary material layer is smaller than that of the outer capillary material layer.

[0037] The specific structure is: the fabric bag 13 provided in the nesting 21 in embodiment 1 is provided with a fabric interlayer 23 to separate the fabric bag 13 into two layers inside and outside; the capillary material is filled in the inside and outside layers of the fabric bag respectively space, and apply different pressures to the capillary materials in the inner and outer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com