High-voltage dragging rubber-sheathed flexible cable for mine

A flexible cable, high-voltage technology, applied in power cables, power cables with shielding/conducting layers, cables, etc., can solve the problems of slow moving speed, insulation damage of insulated cores, easy to twist and break cores, etc. Tensile and tear strength, good tear and drag resistance, protection from damage

Inactive Publication Date: 2013-07-17

JIANGSU ZHONGMEI CABLE

View PDF6 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Three-core cable core insulation is co-extruded with three layers, and the braided metal shielding layer doubles as the ground wire after extruding insulation. ; This type of mobile dragging cable is directly extruded with a single-layer sheath without filling, and the cable has no reinforcement layer, and generally there is no monitoring core

[0004] Existing mine towing mobile rubber cables are generally used on coal mine electric shovels, coal shearers, dredgers, bucket machines, conveyor belts and mobile power distribution devices. In a normal working environment, the moving speed is relatively slow, and the cable is collected and placed on the reel with a large bending radius. The cable does not need to bear the rolling and pulling force of the equipment, but only needs to bear part of its own weight.

[0005] With the continuous emergence of high-voltage and high-power heavy equipment in mines, the existing mobile cables can no longer meet the needs of the equipment

Such high-voltage, high-power equipment is often used in electric shovels, dredgers, buckets and other equipment used in open-pit coal mines. However, the existing cable sheath material is common chlorinated polyethylene or materials with equivalent properties. This sheath material is likely to cause wear and corrosion of the sheath layer in this environment for a long time, thereby affecting the safe service life of the cable; at the same time, Due to the limitation of large-scale construction machinery and equipment, such cables need to be dragged on the construction ground for a long time, and even need to withstand the rolling of equipment. The existing high-voltage mobile rubber cable core is easy to twist and break the core, and the single-layer sheath layer is easy to bulge , the service life is generally only half a year, which increases the user's use cost; secondly, the existing mine towed mobile cable does not have a grounding detection core. Insulation damage is prone to occur in the middle of the cable. If there is no grounding detection core and no reinforcement layer structure, when the main core of the cable is damaged, it cannot be fed back to the monitoring equipment in time, which will easily cause damage to the equipment and may even cause personal injury.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

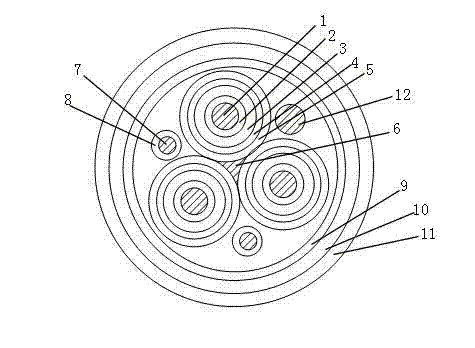

[0022] like figure 2 shown, with figure 1 In contrast, its cable core is formed by twisting three power cores, two monitoring cores and one ground conductor 12 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

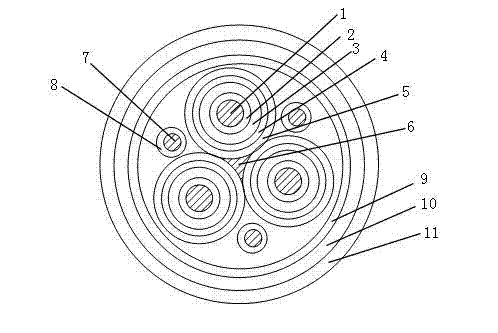

The invention discloses a high-voltage dragging rubber-sheathed flexible cable for mine. The high-voltage dragging rubber jacketed flexible cable comprises a cable conductor which is formed by a plurality of power wire cores and a plurality of pilot wire cores through twisting, an inner sheath is extruded outside the cable conductor, an outer sheath is extruded at the outermost layer of the cable, and a reinforcement layer is woven between the inner sheath and the outer sheath. Each of the three power wire cores is composed of a power conductor and a semi-conductive inner shielding layer, a power wire core insulating layer, a semi-conductive outer shielding layer and a metal shielding layer which are extruded outside the monitoring conductor. By means of the high-voltage dragging rubber-sheathed flexible cable, performances of sheathes are improved, a flexible reinforcement structure is adopted, ground pilot wire cores and the reinforcement layer are added, so that not only the resistance to abrasion and corrosion and the anti-dragging tensile strength of the cable are improved, but also the safe use performance of the cable is added, and the deflection performance of the cable is not affected simultaneously.

Description

[0001] technical field [0002] The invention relates to the field of electric wires and cables, in particular to a mine-used high-voltage trailing rubber-sheathed flexible cable. Background technique [0003] Existing mine towing moving cables generally have three-core, four-core, five-core or six-core structures. Three-core cable core insulation is co-extruded with three layers, and the braided metal shielding layer doubles as the ground wire after extruding insulation. ; This type of mobile towing cable is directly extruded with a single-layer sheath without filling when it is cabled. The cable has no reinforcement layer and generally does not have a monitoring core. [0004] Existing mine towing mobile rubber cables are generally used on coal mine electric shovels, coal shearers, dredgers, bucket machines, conveyor belts and mobile power distribution devices. In the normal working environment, the moving speed is relatively slow, and the cable is collected and placed o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01B9/00H01B9/02

Inventor 储辉施永久刘景光徐庭元

Owner JIANGSU ZHONGMEI CABLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com