Core-shell-structured nano-particles modified with 8-aminoquinoline derivative, and preparation method and application thereof

A nanoparticle, core-shell structure technology, applied in nanotechnology, nanotechnology, nanotechnology and other directions for sensing, can solve the problem of long preparation time, inability to obtain the final product of heavy metal ions, and inability to detect divalent zinc ions And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The concrete steps of preparation are:

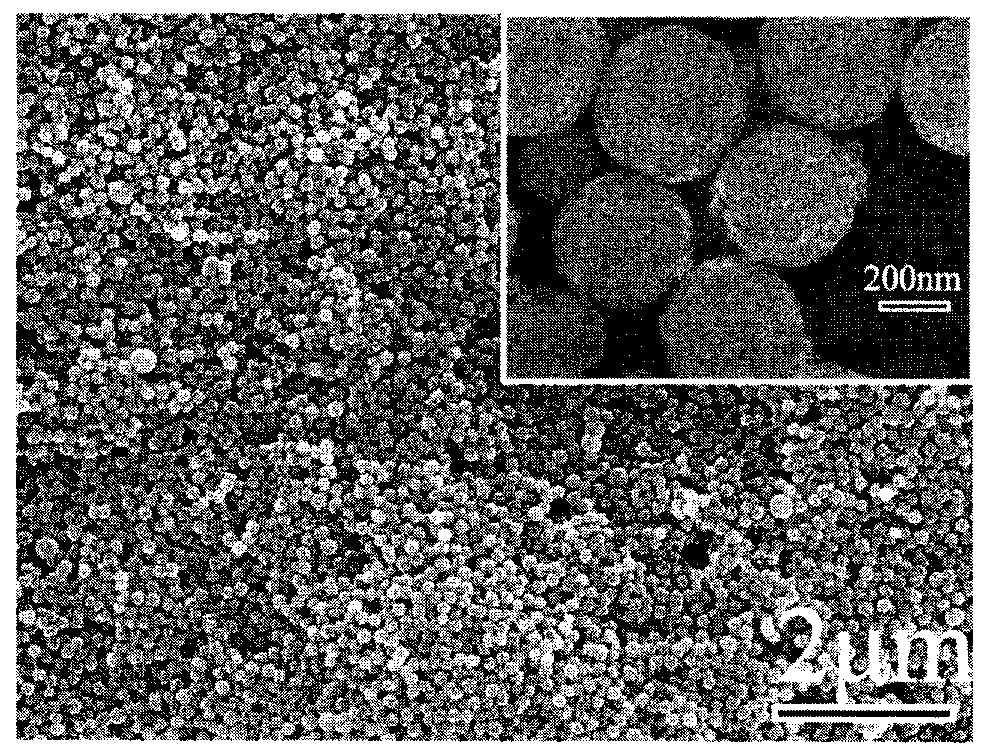

[0032] Step 1, first according to the weight ratio between ferric chloride hexahydrate, sodium acetate and ethylene glycol is 0.8:2.2:30 ratio, iron trichloride hexahydrate and sodium acetate are dissolved in ethylene glycol, and Stir at 45°C until completely dissolved to obtain a precursor solution. Then, the precursor solution was placed in a closed state, and reacted at 200° C. for 8 hours to obtain precipitated iron ferric oxide nanoparticles.

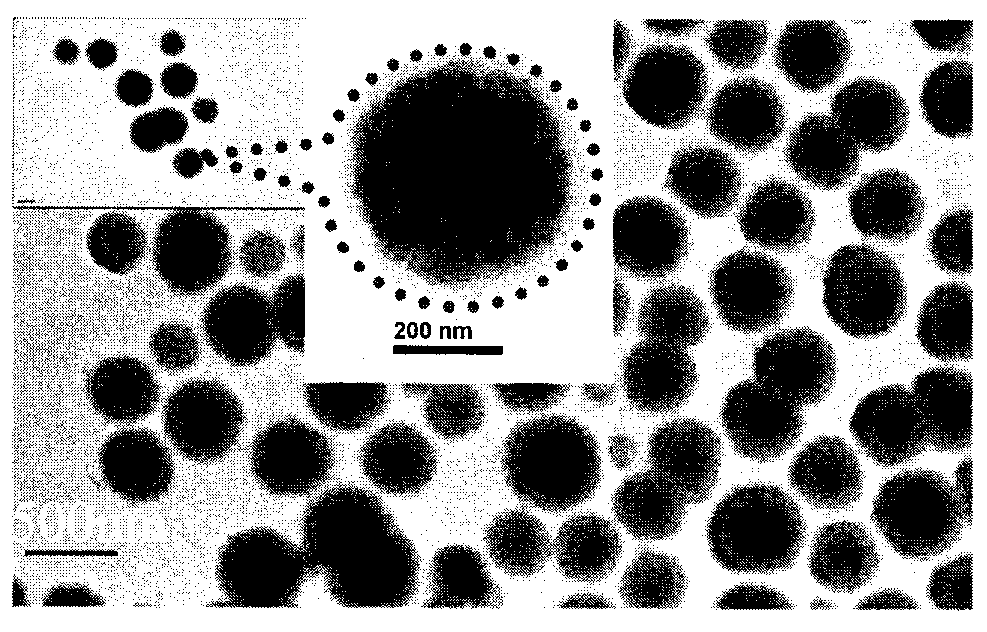

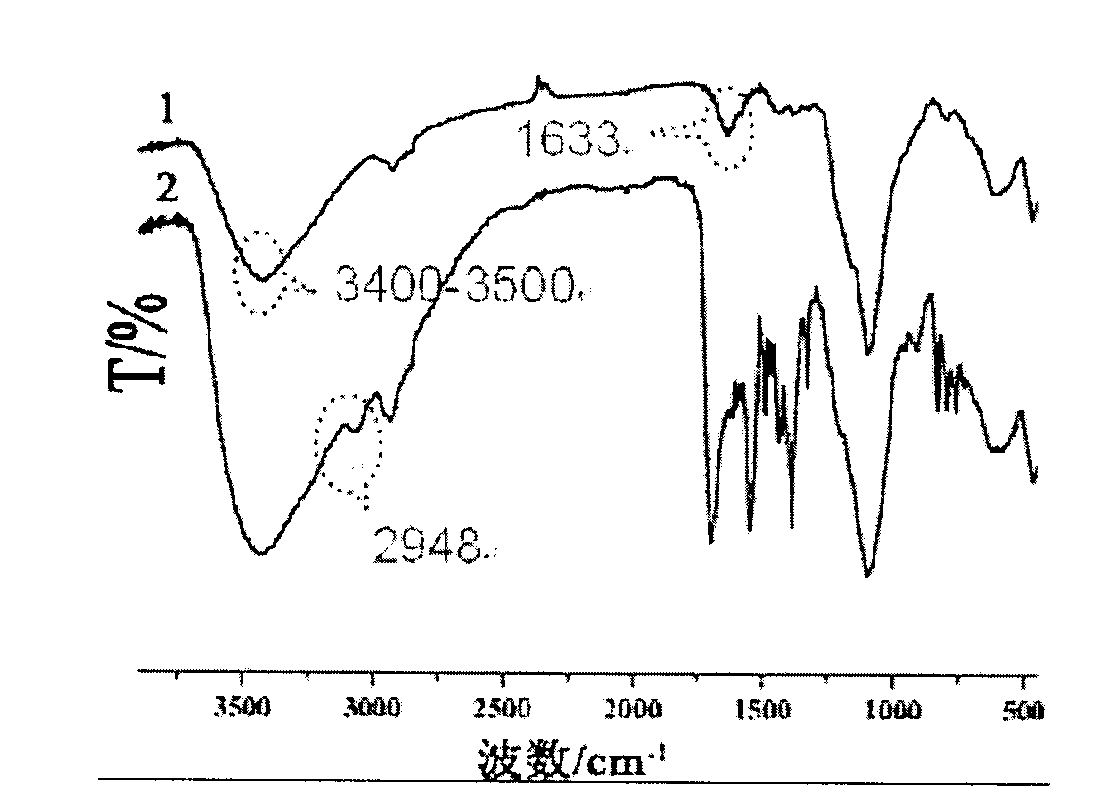

[0033] In step 2, the iron ferric oxide nanoparticles are washed twice with deionized water and ethanol in sequence, and then separated with a magnet. Subsequently, according to the weight ratio between ferric oxide and ethanol of 0.03:5, the iron ferric oxide nanoparticles are dispersed in ethanol to obtain a dispersion liquid. In the dispersion liquid, drip the ammoniacal liquor, deionized water and ethanol that concentration is 26wt% again successively, after mixing uniformly, ob...

Embodiment 2

[0036] The concrete steps of preparation are:

[0037] Step 1, first according to the weight ratio between ferric chloride hexahydrate, sodium acetate and ethylene glycol is the ratio of 0.9:2.1:30, ferric chloride hexahydrate and sodium acetate are dissolved in ethylene glycol, and Stir at 48°C until completely dissolved to obtain a precursor solution. Then, the precursor solution was placed in a closed state, and reacted at 203° C. for 7.5 hours to obtain precipitated iron ferric oxide nanoparticles.

[0038] In step 2, the iron ferric oxide nanoparticles are washed twice with deionized water and ethanol in sequence, and then separated with a magnet. Subsequently, according to the weight ratio between ferric oxide and ethanol of 0.035:5, the nanoparticles of iron ferric oxide are dispersed in ethanol to obtain a dispersion liquid. Then in the dispersion liquid, drip the ammoniacal liquor, deionized water and ethanol that concentration is 27wt% successively, obtain mixed li...

Embodiment 3

[0041] The concrete steps of preparation are:

[0042] Step 1, first according to the weight ratio between ferric chloride hexahydrate, sodium acetate and ethylene glycol is the ratio of 1: 2: 30, ferric chloride hexahydrate and sodium acetate are dissolved in ethylene glycol, and Stir at 50°C until completely dissolved to obtain a precursor solution. Then, the precursor solution was placed in a closed state, and reacted at 205° C. for 7 hours to obtain precipitated iron ferric oxide nanoparticles.

[0043] In step 2, the iron ferric oxide nanoparticles are washed twice with deionized water and ethanol in sequence, and then separated with a magnet. Subsequently, according to the weight ratio between ferric oxide and ethanol of 0.04:5, the nanoparticles of iron ferric oxide are dispersed in ethanol to obtain a dispersion liquid. Then in the dispersion liquid, drip the ammoniacal liquor, deionized water and ethanol that concentration is 28wt% successively, after mixing uniform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Shell thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com