Bearing ball installing groove detector

A technology of bearing balls and mounting grooves, which is applied in the direction of instruments, measuring devices, and mechanical devices, etc., can solve the problems of laborious and time-consuming detection work, lack of special tools for bearing ball mounting grooves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

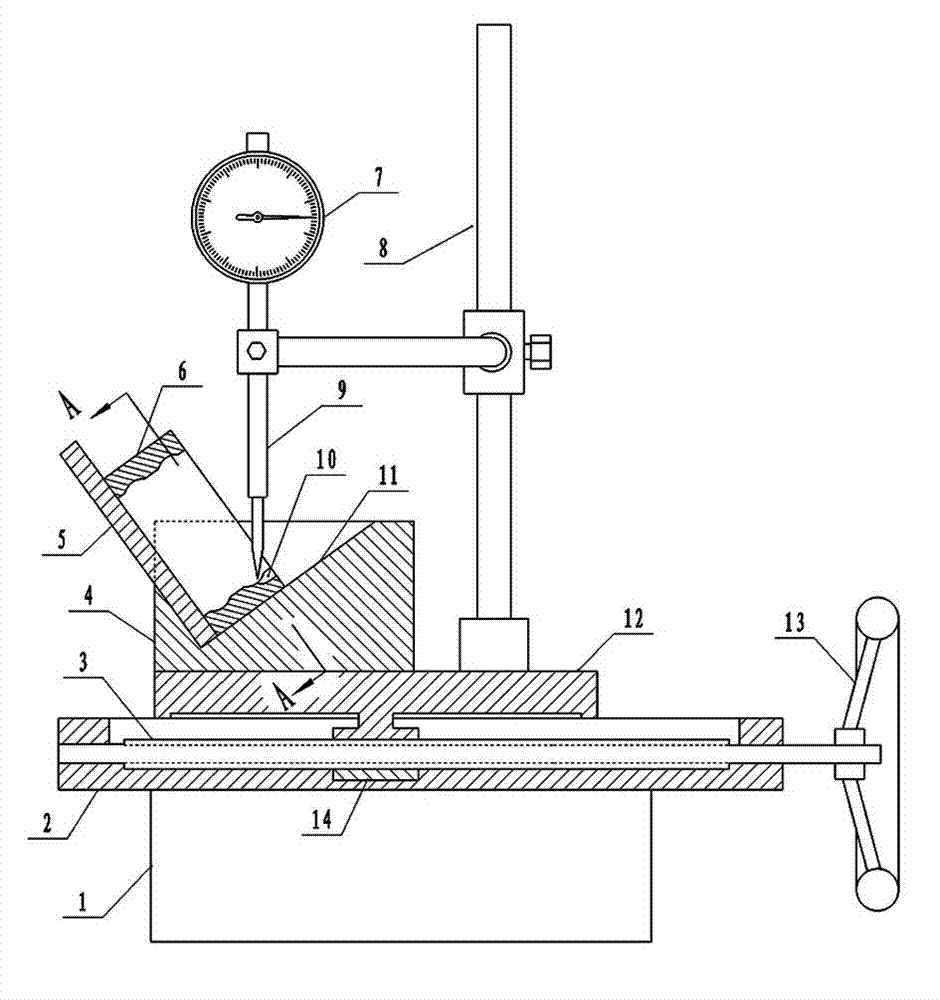

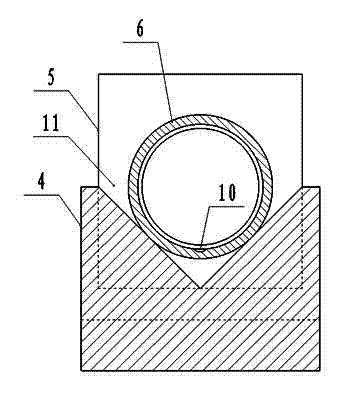

[0008] Example: such as figure 1 with figure 2 As shown, a bearing ball installation groove detector, a fixed plate 2 is installed on the base 1, a screw rod 3 is installed in the middle of the fixed plate 2, a handle 13 is installed on one end of the screw rod 3, and a handle 13 is installed on the surface of the fixed plate 2. Movable plate 12, a nut 14 is fixed under the movable plate 12, the nut 14 is set on the screw rod 3, a positioning block 4 is installed on the movable plate 12, and a "V" shaped chute 11 is designed on the locating block 4, and the chute 11 One end of the chute is equipped with a baffle 5, and the groove bottom of the chute 11 is consistent with the axial direction of the screw rod 3, and the included angle with the horizontal line is 36 0 , A fixed column 8 is installed next to the positioning block 4, and a dial indicator 7 is installed on the fixed column 8. The probe 9 of the dial indicator 7 is facing the bottom of the ball installation groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com