Drum Washing And Drying Machine

A drum washing machine, drum technology, applied to other washing machines, washing machines with containers, household clothes dryers, etc., to achieve the effects of increasing capacity, ensuring assembly space, and minimizing vibration transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Now, embodiments of the present disclosure will be described in detail, examples of which are illustrated in the accompanying drawings, in which like reference numerals designate like elements throughout.

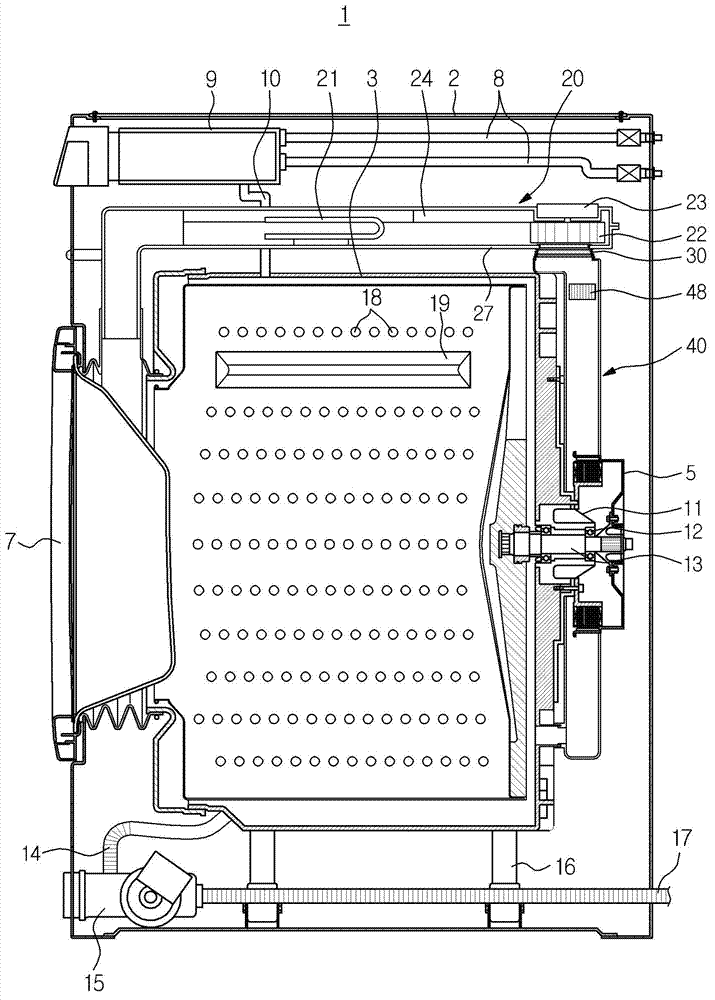

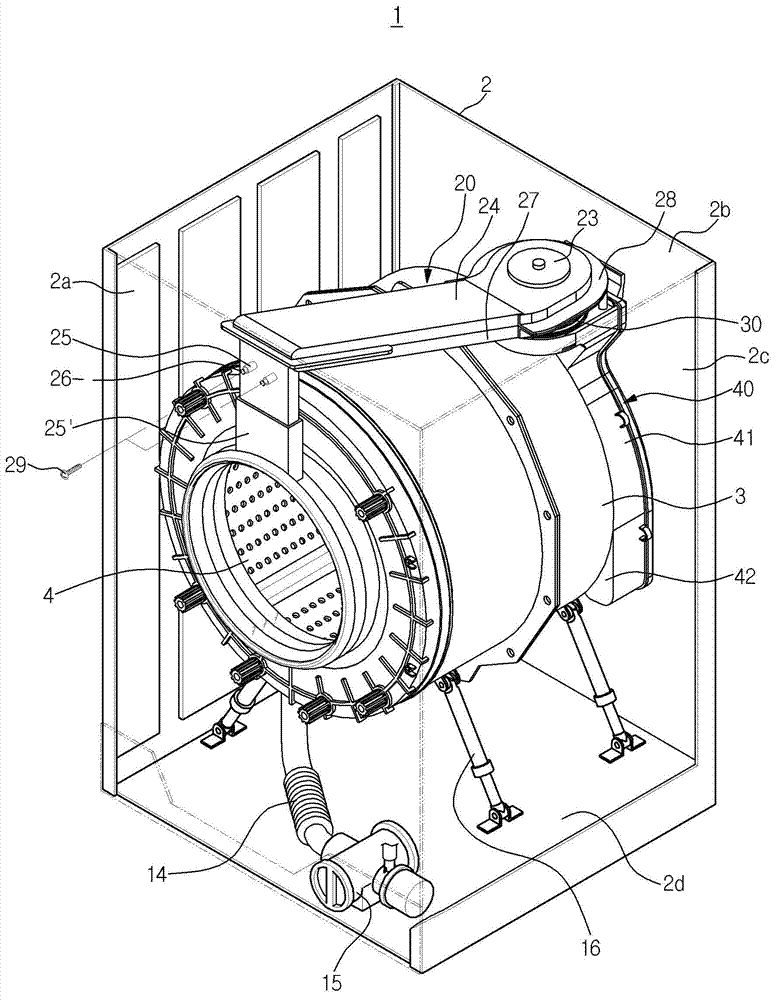

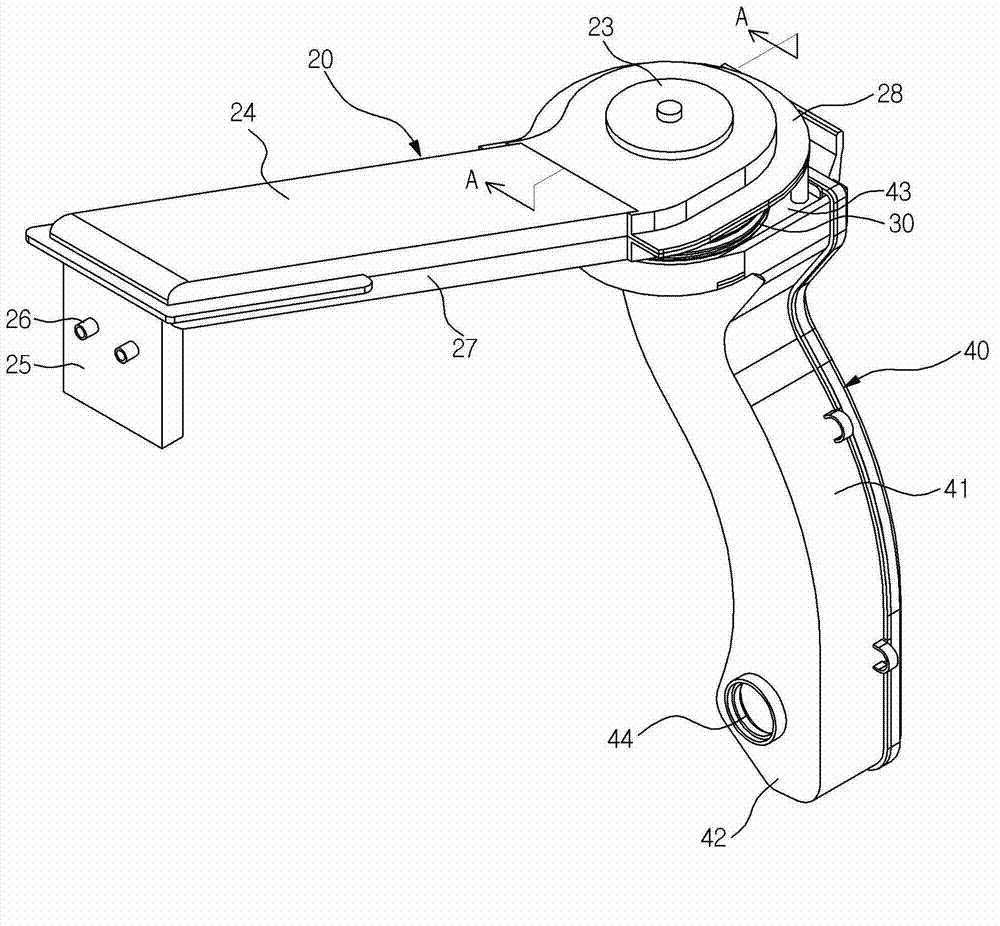

[0044] figure 1 is a view schematically showing a drum washing machine according to an embodiment of the present disclosure, figure 2 is a view schematically showing a combined state of a drying duct and a condensation duct of a drum washing machine according to an embodiment of the present disclosure.

[0045] Such as figure 1 and figure 2 As shown, the drum washing machine 1 includes a casing 2 , a tub 3 disposed inside the casing 2 , a drum 4 rotatably disposed inside the tub 3 , and a motor 5 for driving the drum 4 .

[0046] The casing 2 includes frames 2a, 2b, 2c, and 2d. The frames 2a, 2b, 2c, and 2d include: a front surface frame 2a and a rear surface frame 2b forming the front surface and the rear surface of the casing 2, respectively; The lower surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com