Device and method for regenerating waste rubber at normal pressure, medium temperature and low consumption

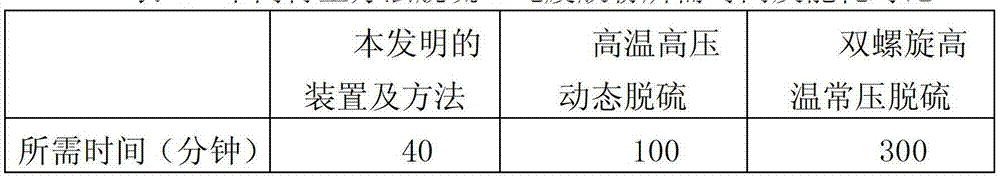

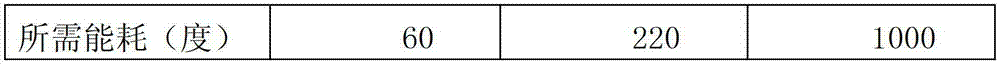

A technology for regenerating waste rubber and waste rubber, which is applied in the direction of climate sustainability, plastic recycling, sustainable manufacturing/processing, etc., can solve the problems of high energy consumption, low production efficiency, and high equipment cost, and achieve low energy consumption and high equipment cost. The effect of low manufacturing cost and short regeneration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

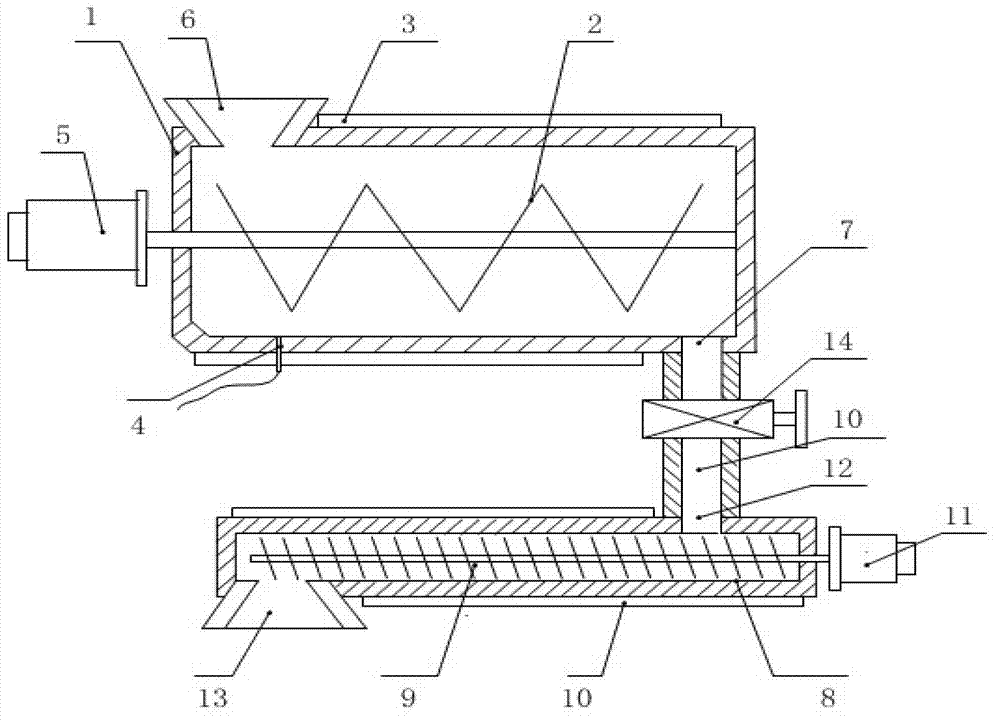

[0024] Example 1: Add 100 parts of 18-mesh tire tread waste rubber powder, 10 parts of pine tar and 0.1 part of 2,2'-disulfide (6-tert-butyl-p-phenol) to the heating reactor tank 1 (tank Body diameter=100cm, length-to-diameter ratio=6:1), close the first material inlet 6, start the paddle drive motor 5 to drive the stirring paddle 2 to stir the material, and heat the tank body by electric heating 3 to heat up the material according to the temperature The temperature in the tank measured by the sensor 4 rises to 200°C. After continuing to react for 20 minutes, open the connecting valve 14, so that the material in the tank enters the two-layer cooler cylinder 8 connected in series from the first material outlet 7 within 2 minutes, and at the same time Start the screw drive motor 11, and let the cooling medium pass through the cooling channel 10, and the screw transports the material for 10 minutes to cool the temperature to 60°C, and then the material can be taken from the second...

Embodiment 2

[0030]Example 2: Add 100 parts of waste ethylene-propylene rubber, 10 parts of naphthenic oil, 15 parts of paraffin oil and 3 parts of n-butylamine into the heating reactor tank 1 (tank diameter=100cm, aspect ratio=6:1 ), close the first material inlet 6, start the paddle drive motor 5 to drive the stirring paddle 2 to stir the material, heat the tank body by electric heating 3 to raise the temperature of the material, and the temperature inside the tank is measured by the temperature sensor 4 to rise to 250°C. After continuing to react for 40 minutes, open the connection valve 14, so that the material in the tank enters the single-layer cooler cylinder 8 within 2 minutes from the first material outlet 7, and at the same time starts the screw drive motor 11, and makes the inside of the cooling channel 10 The cooling medium is introduced, and the material is conveyed by the screw for 12 minutes to cool the temperature to 75°C, and then the material can be taken from the second m...

Embodiment 3

[0032] Example 3: Add 100 parts of waste butyl rubber, 5 parts of rosin and 2.0 parts of cetylamine into the heating reactor tank 1 (tank diameter=100cm, aspect ratio=6:1), close The first material inlet 6, start the paddle drive motor 5 to drive the stirring paddle 2 to stir the material, heat the tank body by electric heating 3 to heat up the material, and the temperature in the tank is measured by the temperature sensor 4. The temperature rises to 160°C, and the reaction continues for 15 minutes , open the connection valve 14, so that the material in the tank enters the two-layer cooler cylinder 8 in series from the first material outlet 7 within 2 minutes, and at the same time starts the screw drive motor 11, and makes the cooling channel 10 pass into the cooling medium, the screw transports the material for 8 minutes to cool it down to 50°C, and then the material can be taken from the second material outlet 13, thus completing a waste rubber regeneration process; in additi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com