Alkylol amine and preparation method

A technology of alcohol amine and monoethanol amine, which is applied in the field of material engineering to achieve the effects of controllable process, high purity and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0011] From the perspective of the preparation method of the alcohol amine, it includes the following main steps: 1. Add monoethanolamine to the reactor under negative pressure, and fill the reactor with nitrogen to replace the air in the reactor; 2. Start the external circulation to adjust the temperature to 40 ± After 2°C, vacuum up to the highest negative pressure; Ⅲ. Turn off the vacuum and close the reaction kettle, heat the monoethanolamine in it to 90-100°C, then add propylene oxide to carry out circular reaction, and the reaction temperature is controlled at 90-110°C . The reaction pressure is less than 0.35MPa; Ⅳ. Keep warm at 90-110°C for a period of time until the pressure in the reactor no longer drops, and then stop the external circulation and discharge the material after cooling to 50-60°C. The reaction molar ratio of the above monoethanolamine and propylene oxide is 1:2.

[0012] As an optimization of the above technical scheme, in step III, before adding propy...

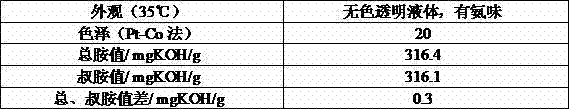

Embodiment 1

[0014] Example 1: Put 610 kg of monoethanolamine into a clean and dry 2000L external circulation atomization kettle under negative pressure, fill with nitrogen to replace the air in the kettle, start the canned pump to adjust the temperature of the external circulation, and vacuumize at 42°C After 41 minutes, the negative pressure reaches the highest level, close the vacuum valve, and close the reactor; slowly heat the monoethanolamine to 95°C, stop heating, spray 10 kg of propylene oxide from the top of the reactor, and the pressure in the reactor will decrease after 5 minutes. Fall back, and then continuously add propylene oxide. With the addition of propylene oxide, the material reacts, the temperature in the kettle naturally rises gradually, and the pressure in the kettle increases; the material in the kettle is drawn from the bottom of the kettle by the canned pump, pressurized by the canned pump, and adjusted by the heat exchanger Atomize from the top of the kettle and t...

Embodiment 2

[0015] Example 2: Under negative pressure, put 500 kg of monoethanolamine into a clean and dry 2000L external circulation atomization kettle, fill with nitrogen to replace the air in the kettle, start the canned pump to adjust the temperature of the external circulation, and vacuumize at 39°C After 32 minutes, the negative pressure reaches the highest level, close the vacuum valve, and close the reactor; slowly heat the monoethanolamine to 100°C, stop heating, spray 8 kg of propylene oxide from the top of the reactor, and the pressure in the reactor will decrease after 5 minutes. Fall back, and then continuously add propylene oxide. With the addition of propylene oxide, the material reacts, the temperature in the kettle naturally rises gradually, and the pressure in the kettle increases; the material in the kettle is drawn from the bottom of the kettle by the canned pump, pressurized by the canned pump, and adjusted by the heat exchanger Atomize from the top of the kettle and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com