Whole-house quality-divided purification method

A purification device and quality separation technology, applied in the field of water purification, can solve problems such as cumbersome process and energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

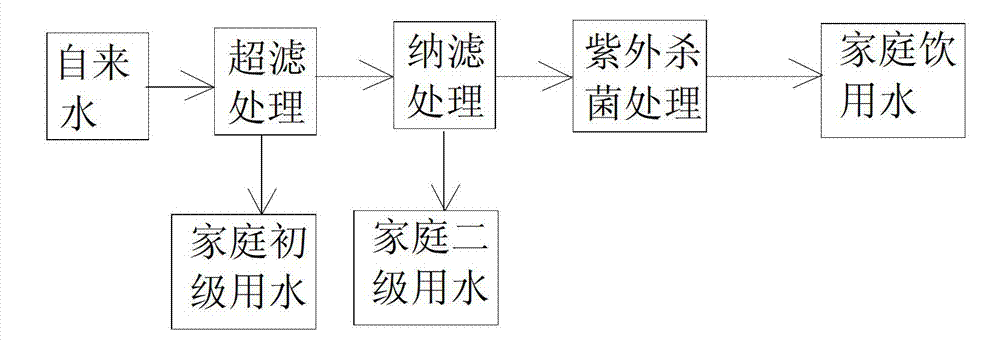

[0030] The tap water inlet pressure of a household on the first floor of a user is 0.3MPa, the inlet water turbidity is 3NTU, and the residual chlorine content is 0.05ppm. figure 1 As shown, the tap water is sequentially processed by ultrafiltration, nanofiltration and ultraviolet sterilization. Ultrafiltration treatment adopts hollow fiber membrane, the material is polyvinylidene fluoride, and the molecular weight cut-off is 200,000 Daltons. The concentrated water after ultrafiltration is used for flushing mops or toilets or watering flowers, and the turbidity of ultrafiltration water is less than 0.1NTU. The molecular weight cut-off of the nanofiltration module is 3000 Daltons, the operating pressure is 0.2 MPa, and the water production rate is 300L / h. Concentrated water after nanofiltration treatment can be used for washing vegetables and washing basins, etc., while nanofiltration water can be used as direct drinking water or kitchen cooking water after ultraviolet sterili...

Embodiment 2

[0034] The tap water inlet pressure of residents on the sixth floor of a community is 0.1MPa, the inlet water turbidity is 8 NTU, and the residual chlorine content is 0.3ppm. Such as image 3 As shown, the tap water is sequentially processed by pressurization, microfiltration, ultrafiltration, dechlorination, nanofiltration and ultraviolet sterilization. A booster pump is used for the boosting treatment, and the head of the booster pump is 20 meters. A microfiltration filter is used for the microfiltration treatment, and the filtration accuracy of the microfiltration filter is 50 μm. The ultrafiltration process adopts hollow fiber membrane, which is made of polypropylene and has a molecular weight cut-off of 80,000 Daltons. The concentrated water after ultrafiltration is used for flushing mops or toilets or watering flowers, and the turbidity of ultrafiltration water is less than 0.1NTU. Activated carbon filter is used for chlorine removal treatment, and coconut shell activa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com