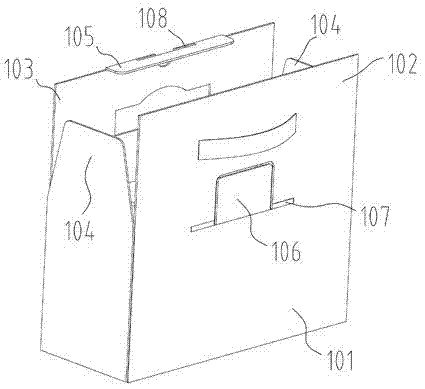

Automatic paper gift-box packing forming device and forming processes

An automatic packaging and forming device technology, applied in packaging and other fields, can solve problems such as numerous influencing factors, difficult management, and difficult control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

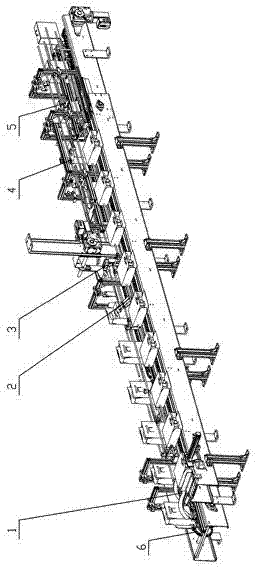

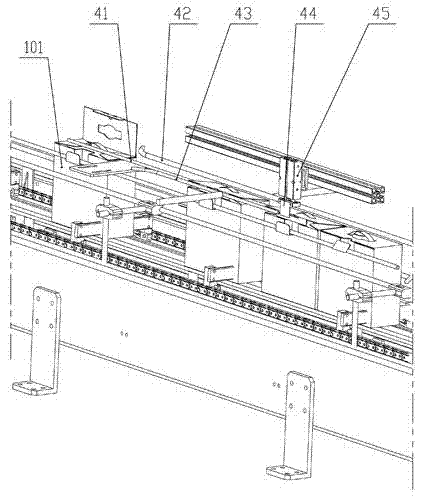

[0026] Such as Figure 5 shown.

[0027] The gift box package carton automatic packaging forming device according to the present invention includes a conveyor belt 6 that drives the gift box package to each station, and a vertical box mechanism 1 that sends the gift box package carton to the conveyor belt 6. The vertical box mechanism 1 includes a detection carton The detection switch 11 sent in pushes the carton into the sliding cylinder 12 on the conveyor belt 6, and the slideway 13 for the carton to slide down, wherein the detection switch 11 and the sliding cylinder 12 are arranged on the side top of the conveyor belt 6, and the slideway 13 is from The detection switch 11 extends to the top of the conveyor belt 6, and the other side of the conveyor belt 6 relative to the slideway 13 is provided with an upright box baffle 14 for guiding the sliding cartons, and for guiding the movement of the cartons on the conveyor belt 6. Belt 15; There is also the vertical box cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com