An Intelligent Control System Conducive to Improving Excavator Heat Dissipation Efficiency

An intelligent control system and heat dissipation efficiency technology, which is applied to the cooling of the engine, mechanical equipment, engine components, etc., can solve the problems of difficult layout, increased noise of the fan, and influence on the heat dissipation effect, so as to intelligently control the fan speed and improve the heat dissipation efficiency , good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

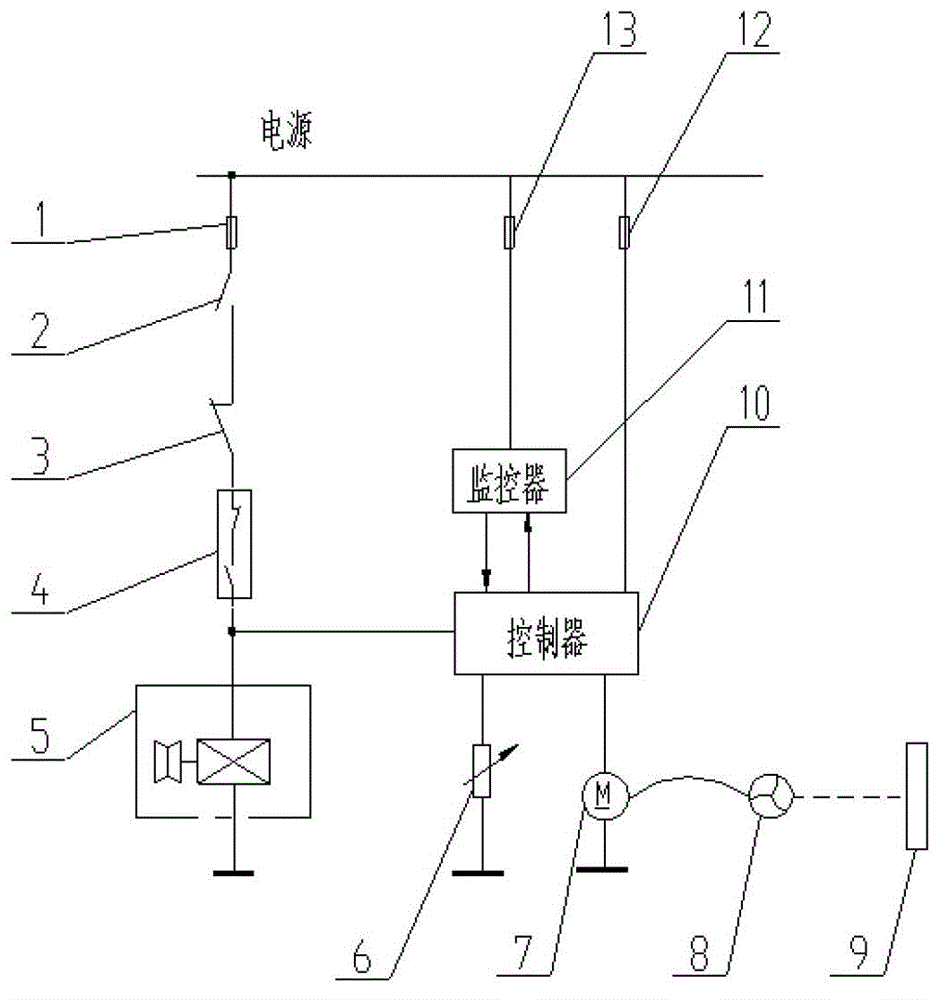

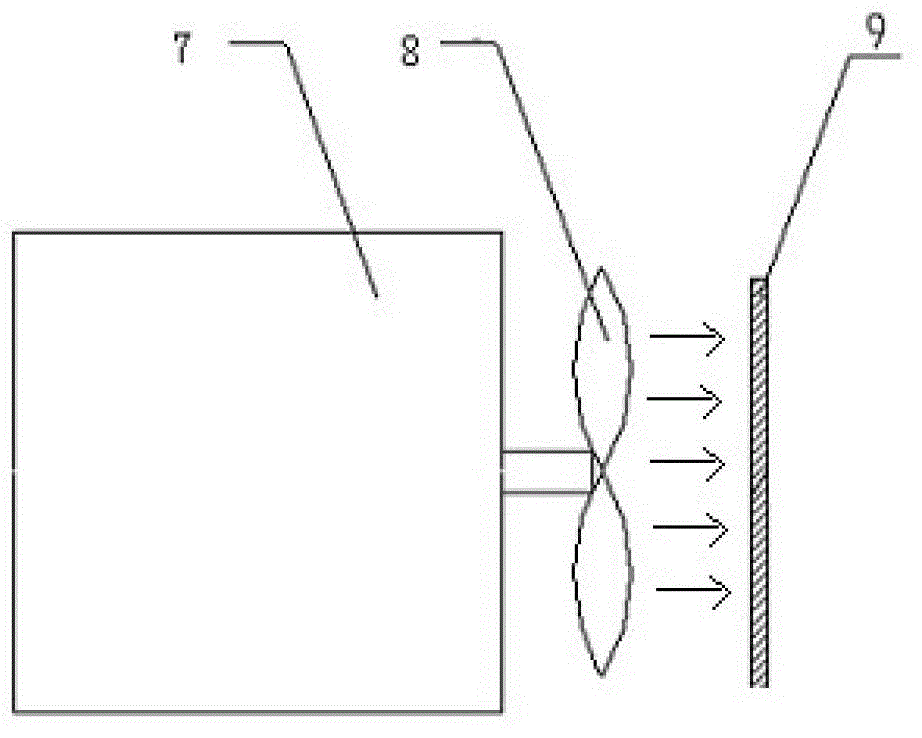

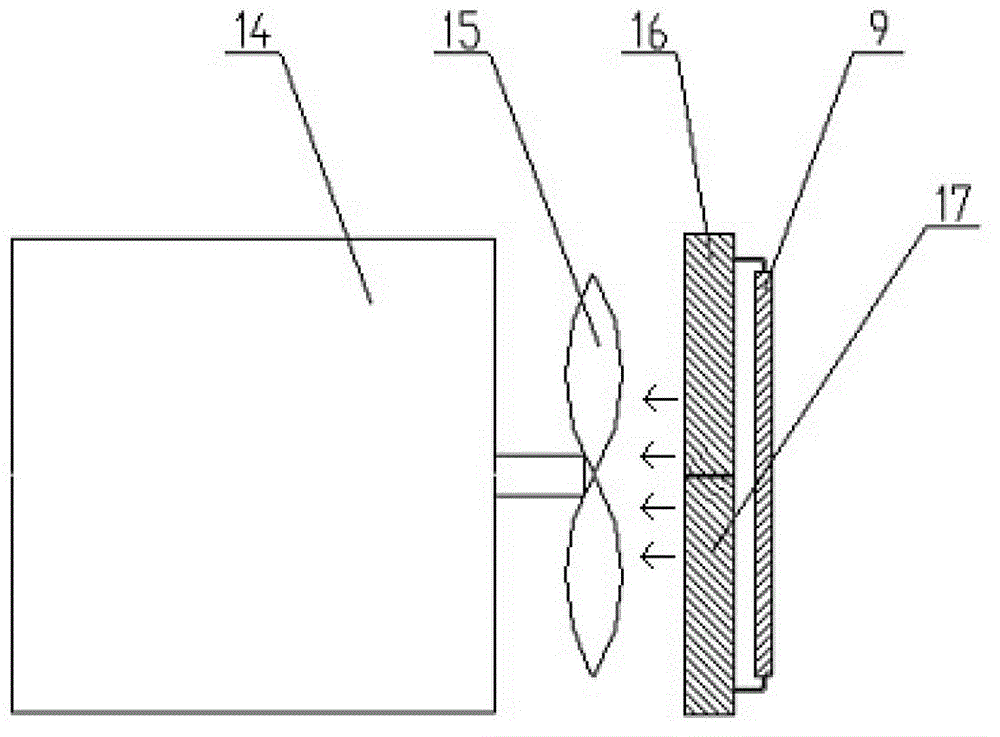

[0016] Such as figure 1 and figure 2 As shown, the cooling system of the air conditioner condenser includes engine 14, engine fan 15, engine cooling water radiator 16, hydraulic oil radiator 17, power supply, fuse A1, air conditioner switch 2, thermostat 3, high and low voltage switch 4, Compressor clutch 5, air conditioner condenser 9, temperature sensor 6, fan motor 7, fan 8, fuse B12 and controller 10 connected to the high and low pressure switch 4 and compressor clutch 5, engine cooling water radiator 16 and hydraulic pressure The oil radiator 17 is placed in parallel in front of the engine fan 15 connected to the engine 14, one end of the fuse A1 is connected to the power supply, the other end is connected to one end of the thermostat 3 through the air conditioner switch 2, and the other end of the thermostat 3 is connected through the high and low voltage switch 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com