Coiler side guide plate control method for preventing steel coils on hot rolling production line from staggering

A control method and side guide plate technology, applied in rolling mill control devices, metal rolling, tail end control, etc., can solve problems such as the difficulty in determining the compensation value, the quality of edge damage, etc., achieve large wear tolerances, and improve coil shape , The effect of preventing the tail of the steel coil from being staggered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

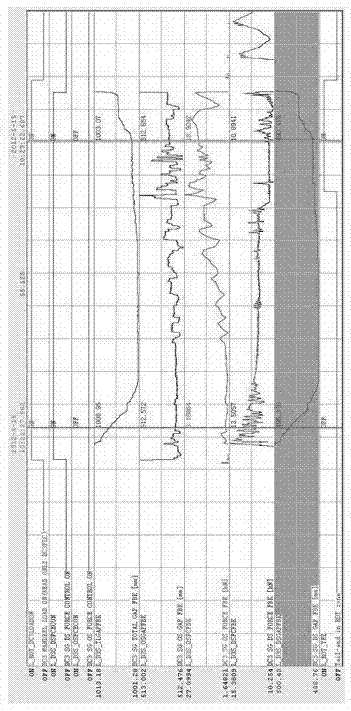

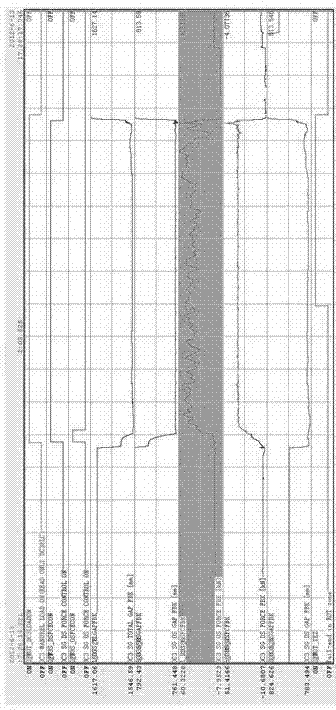

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below through embodiment.

[0016] A side guide plate control method of a coiler to prevent coil misalignment in a hot rolling production line. The two side guide plates of the coiler are respectively the pressure control side and the position control side, respectively referred to as the force control side and the position control side; Change the programming in the side guide control PLC of the machine, and add a force control link to the side guide control logic on the position control side. steel, and then turn into position control.

[0017] Before the strip enters the coiler, the control of the two side guide plates is the same as that of the background technology, and its opening is set at the width of the strip plus a preset value; after the strip enters the pinch roller of the coiler, the two side guides The guide plate opening is set to the width of the strip. After the setting is completed, when the coiler shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com