Planetary gear reducer

A technology of gear reducer and planetary gear, which is applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problem of increased manufacturing cost of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

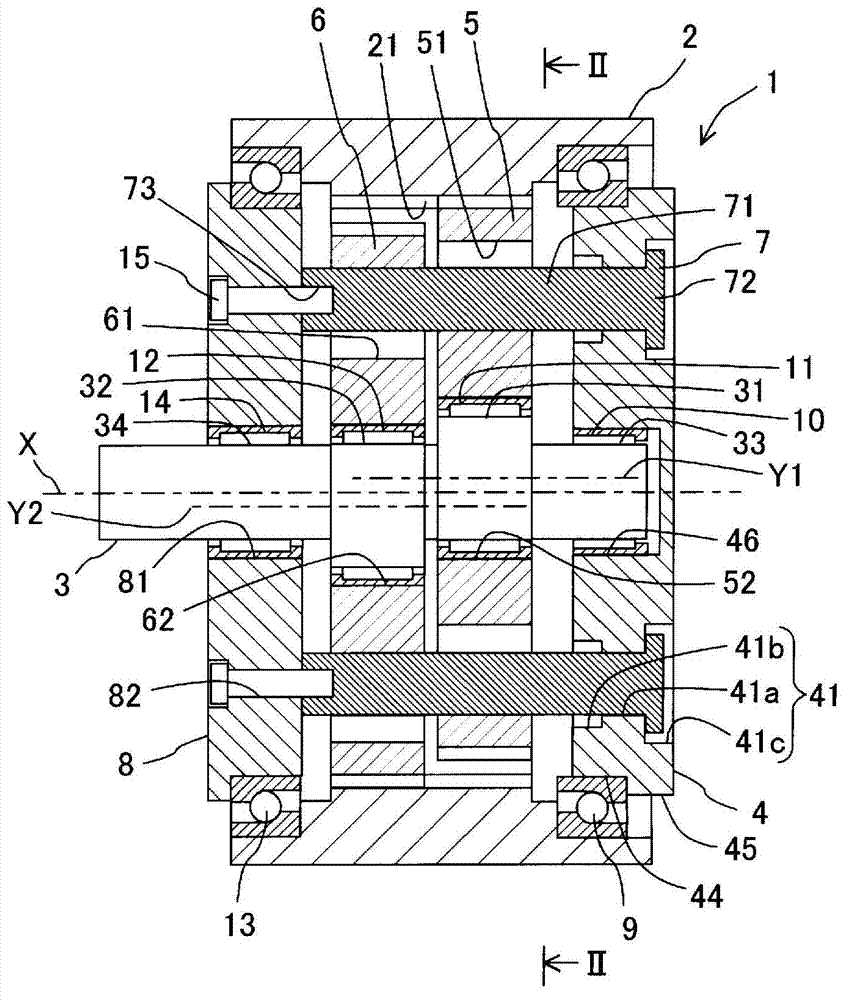

[0031] refer to figure 1 and figure 2 The planetary gear reducer 1 of this embodiment will be described. The planetary speed reducer 1 of the present embodiment is configured such that the eccentric cam portions 31 and 32 of the crankshaft 3 are configured as eccentric portions, and includes planetary gears as external gears rotatably supported by the eccentric cam portions 31 and 32 , respectively. 5, 6 these two gears, and the two planetary gears 5, 6 are configured to be clamped by the first side plate 4 and the second side plate 8 as the planetary gear carrier.

[0032]Specifically, the planetary gear reducer 1 is configured as follows. This planetary gear reducer 1 mainly includes a housing 2 , a crankshaft 3 , a first side plate 4 as a carrier, a second side plate 8 , a first planetary gear 5 , a second planetary gear 6 , and a plurality of pins 7 . The housing 2 is formed in a cylindrical shape, and an internal gear 21 is formed on the inner peripheral surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com