Ultra-thin dot matrix display device and production method thereof

A production method and display technology, applied to instruments, identification devices, etc., can solve problems such as unstable product performance, low efficiency, and increased manufacturing costs, and achieve the effects of stable and reliable product quality, simplified manufacturing processes, and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

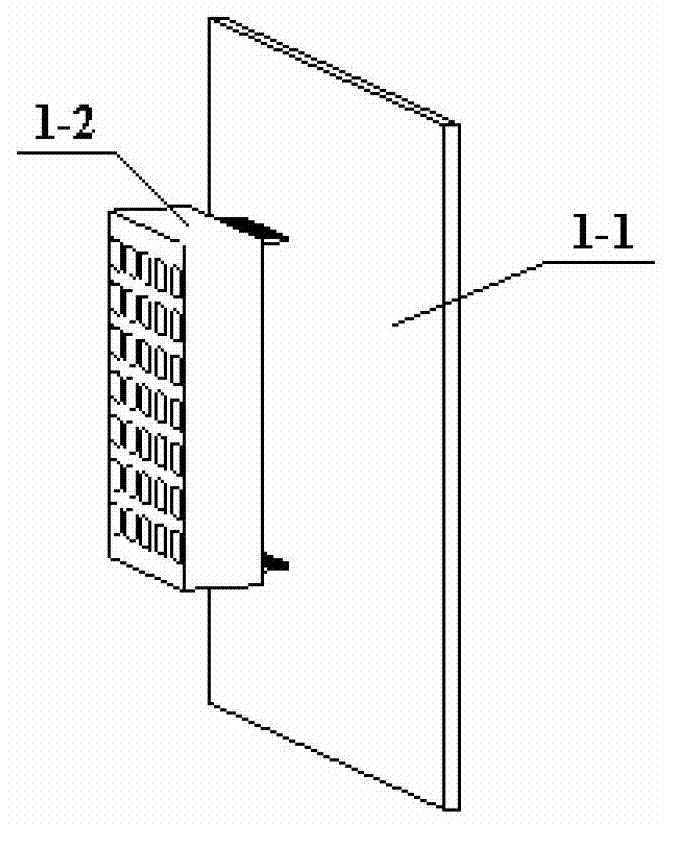

[0023] figure 1 is a structural schematic diagram of a dot-matrix display in the prior art, by figure 1 It can be seen that the dot matrix display in the prior art is composed of a PCB circuit board 1-1 and a dot matrix display module 1-2. The dot matrix display module 1-2 is purchased from the market and has a thickness of 8-9mm. If it is customized by mold opening, the limit size is also 5mm thick, which is still too thick for the call box. Moreover, this type of module usually uses in-line pins, which require lead-out solder joints on the back of the circuit board, and the solder joints will increase the thickness by 1mm. Moreover, if in-line pins are used, it is also necessary to make contact with the bottom plate of the call box. Insulation protection treatment; if patch pins are used, it will be necessary to increase the size of the module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com