Methyl iodide gas sampling system applicable to high pressure steam pipeline environment

A high-pressure steam and gas sampling technology, used in sampling devices, radiation measurement, instruments, etc., can solve problems such as inability to meet measurement requirements, adjustment and processing of gas state parameters, and poor economy, and meet system performance testing requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

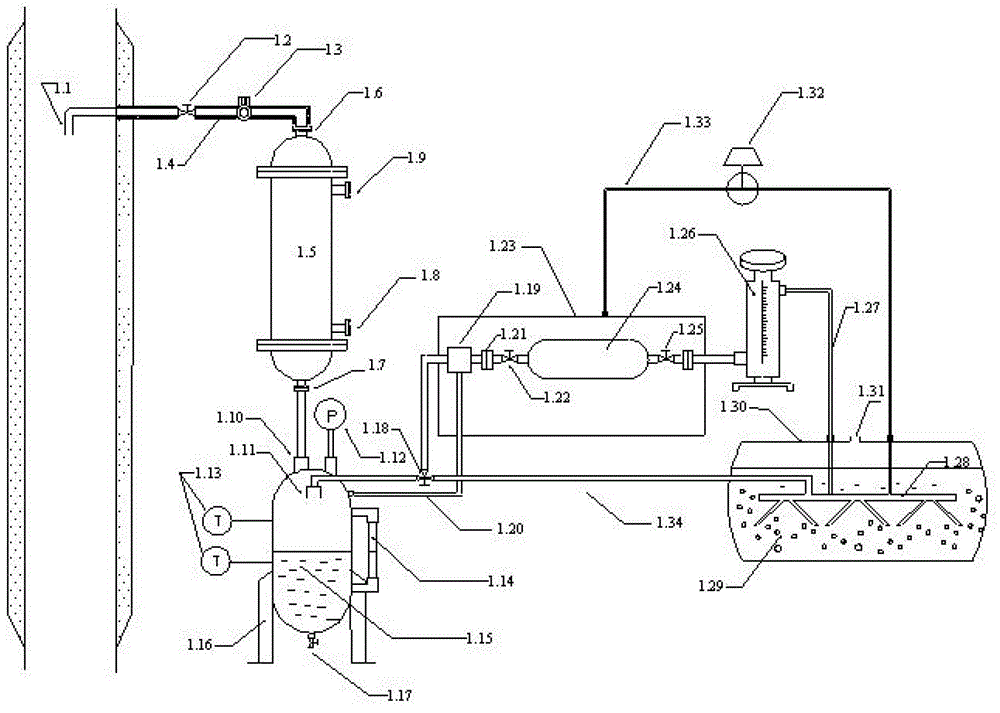

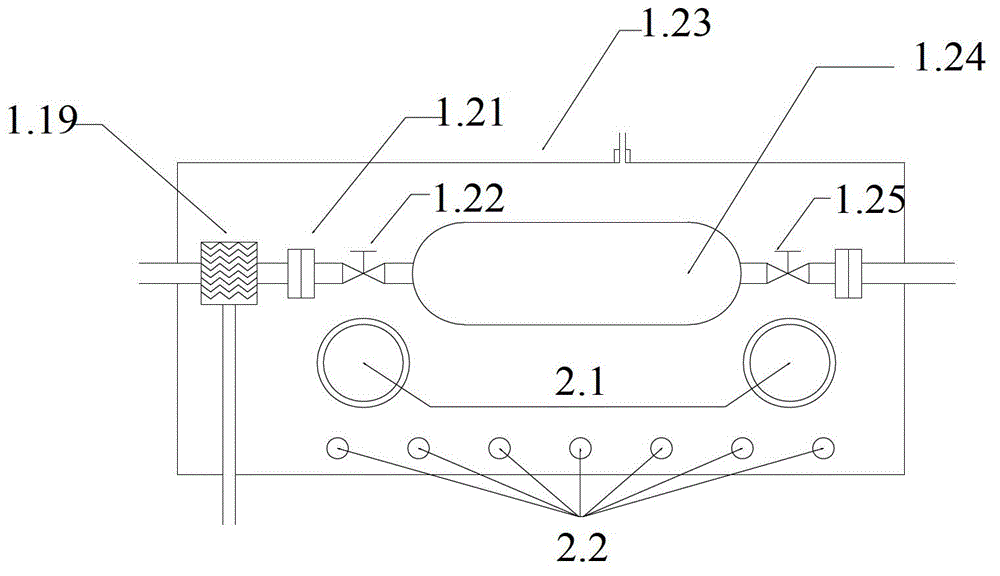

[0015] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0016] combine Figure 1~2 , the mixed gas depressurization part, the inverted L-shaped sampling inlet 1.1 is 180 degrees to the gas flow direction, and is sealed by welding at the outlet of the steam pipe. The heating belt pipe section is a stainless steel pipe with a diameter of 8mm, and the outer layer is wound with an electric heating belt 1.4, The heating power can be adjusted through the temperature control device according to the gas state parameters to ensure that the gas is in a slightly overheated state. A high-temperature and high-pressure stop valve 1.2 is installed on the side close to the main steam pipeline to control the on-off of the sampling pipeline. The stop valve 1.2 is connected to the high temperature resistant pressure regulating valve 1.3 through a stainless steel pipeline, which can adjust the pressure to the required value according to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com