Rockwell hardness judging method of thin-specification Cr-Ni system austenite stainless steel plate

A technology of austenitic stainless steel and Rockwell hardness, applied in the field of Rockwell hardness determination of thin gauge Cr-Ni austenitic stainless steel plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] (1) Supply standard ASTM A 240 / 240M, grade 304 / 304L, surface 2B, specification 18GA×60″×C, weight 12399 pounds, hardness HRB84.0 (measure Hv166, then Rockwell hardness B is 166 / 1.98 =83.8, determined as HRB84.0 according to the carry rule).

[0018] (2) Supply standard ASTM A 240 / 240M, grade 316 / 316L, surface 2B, specification 20GA×60″×C, weight 15880 pounds, hardness HRB84.0 (measure Hv165, then Rockwell hardness B is 165 / 1.98 =83.3, determined as HRB83.0 according to the carry rule.

[0019] Production date: in July of a certain year, the grade of the same heat treatment unit, the same production process, and the same chemical composition is 304 steel plate, and its thickness specification is: 2mm to 6mm.

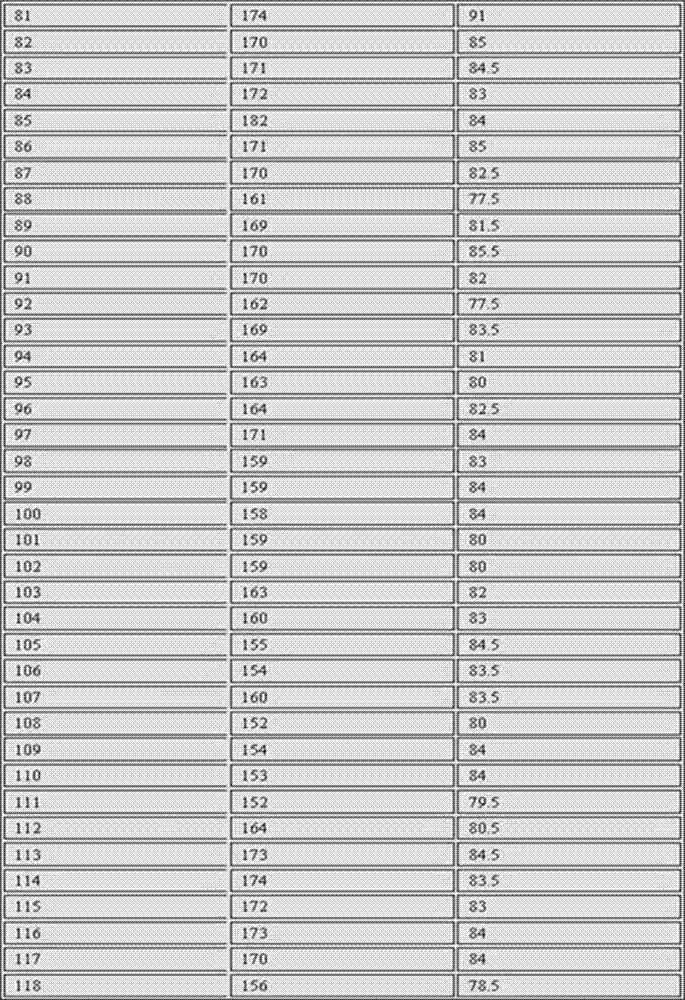

[0020] Explanation: the obtaining test data of empirical formula of the present invention sees the following form:

[0021]

[0022]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com