Teaching simulation test method of pure bending beam

A simulation test and pure bending technology, which is applied in the field of pure bending beam teaching simulation test, can solve the problems of beam body difficult to handle, difficult to transport, long test period, etc., and achieve the effect of high work efficiency, convenient transportation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

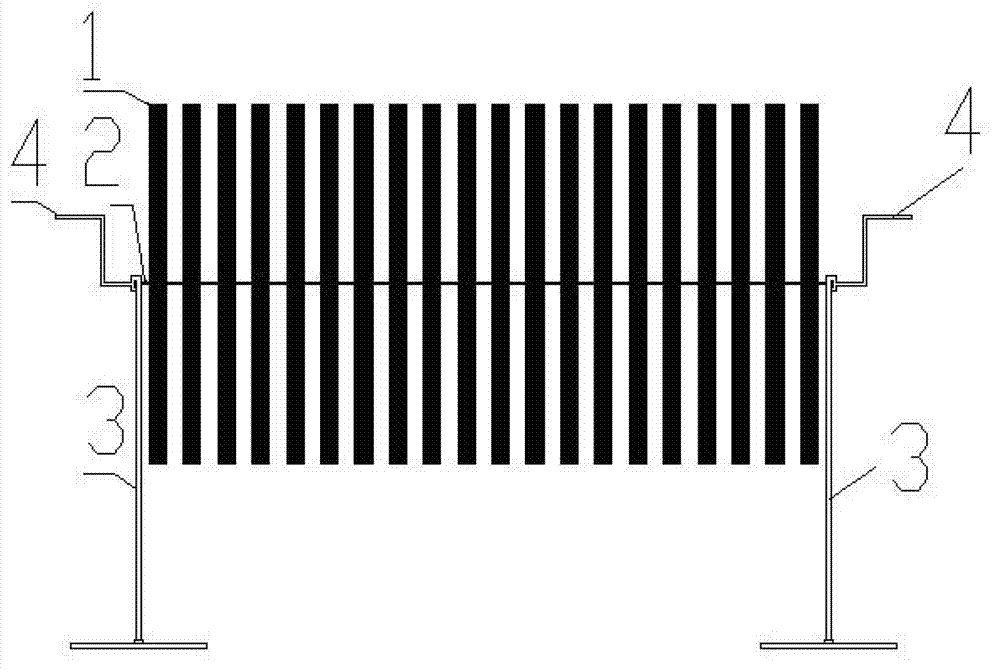

[0014] The pure bending beam teaching simulation test method of the present invention is that the transverse direction of the beam body is simulated by the combined rigid sheet, the longitudinal direction of the beam body is simulated by the axis of the center sheet, and the beam body is simulated by adding force to the beam body through the force bending handle on the outside of the support; Horizontally combine the rigid pieces to achieve the plane assumption condition, connect the horizontally combined rigid pieces through the longitudinal center axis to form a whole beam body, and support the whole beam body by the support. The bending deformation of the body is caused by the force; the deformation of the cross section of the beam body is observed through the rotation of the transverse combined rigid sheet, and the experimental demonstration process of the deformation of the longitudinal section is observed through the stretching and closing of the upper and lower ends of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com