Self-anchorage track laying type bridge inspection vehicle

A bridge inspection vehicle and self-anchoring technology, applied in bridges, bridge parts, bridge construction and other directions, can solve the problems of inconvenient self-running, affecting the passage of lines, unable to obtain reliable bearing bodies, etc., achieving compactness, low cost, wide application range, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

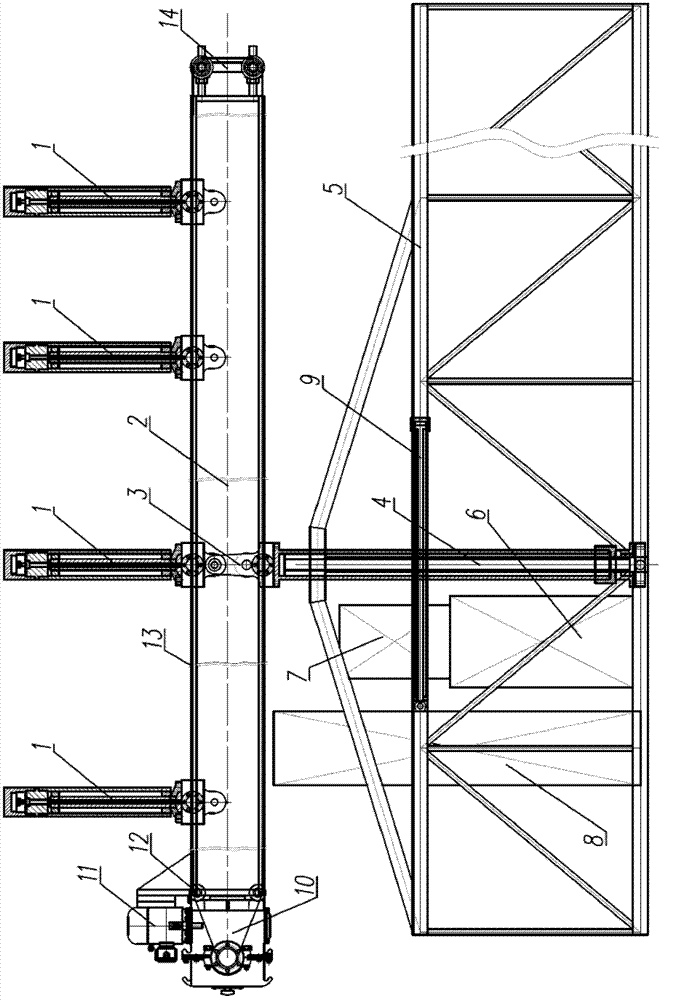

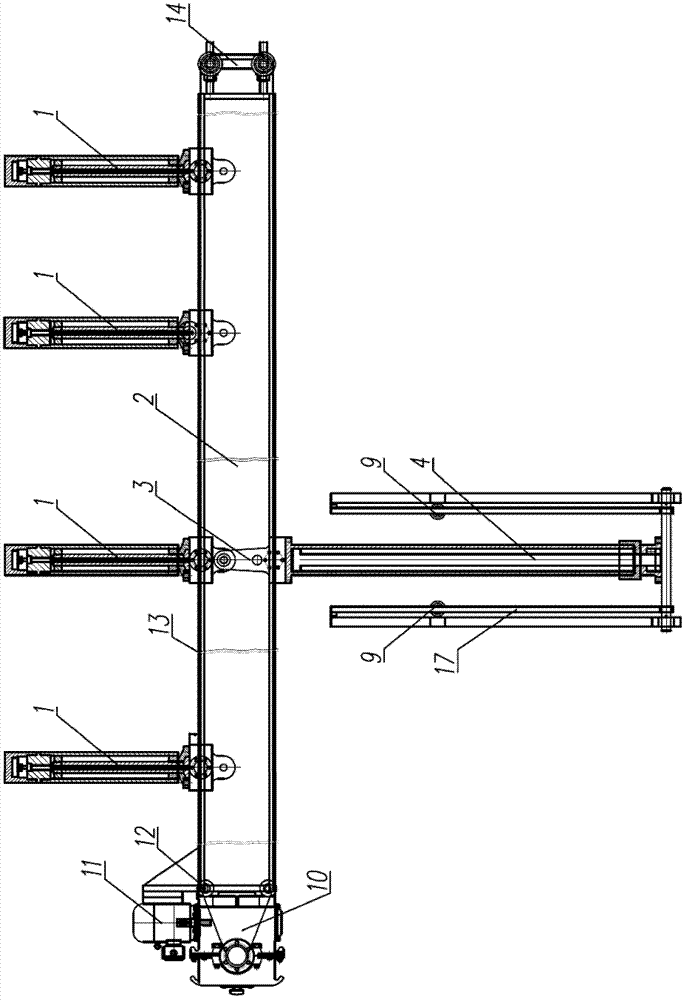

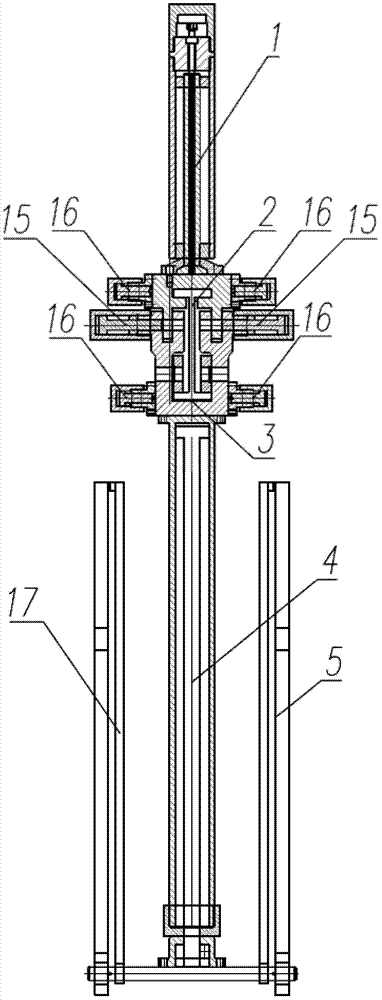

[0045] like figure 1 , figure 2 ,and image 3The self-anchored track-laying bridge inspection vehicle shown in the figure consists of four groups of anchoring and hanging system 1, inspection running track 2, inspection arm sliding system 3, inspection arm lifting system 4, inspection arm 5, hydraulic pump station 6, engine 7, balance assembly 8. Drive system (including worm gear reducer 10, motor 11, jointless wire rope 13, rope presser 16, wire rope guide wheel 12, wire rope tensioning device 14), detection arm automatic balance control system (including balance distribution Weight 8, balance hydraulic cylinder 9, balance detection system switch circuit 17), beam bottom anchor 18, activity detection platform 19, hydraulic pipeline (not shown in the figure), drive circuit composition (not shown in the figure). The four sets of anchor suspension system 1 are assembled on the detection running track 2 through the upper gantry 112 with a sliding pair. The detection running tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com