Preparation method of polymer photonic crystal with wide-range adjustable photonic bandgap

A technology of photonic crystals and photonic bandgap, which is applied in the field of preparation of polymer photonic crystals, can solve the problems of three-dimensional photonic crystals that are difficult to order in a large area, limited response range, and high cost, and achieve excellent size monodisperse properties and easy deposition and assembly , the effect of narrow half-peak width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

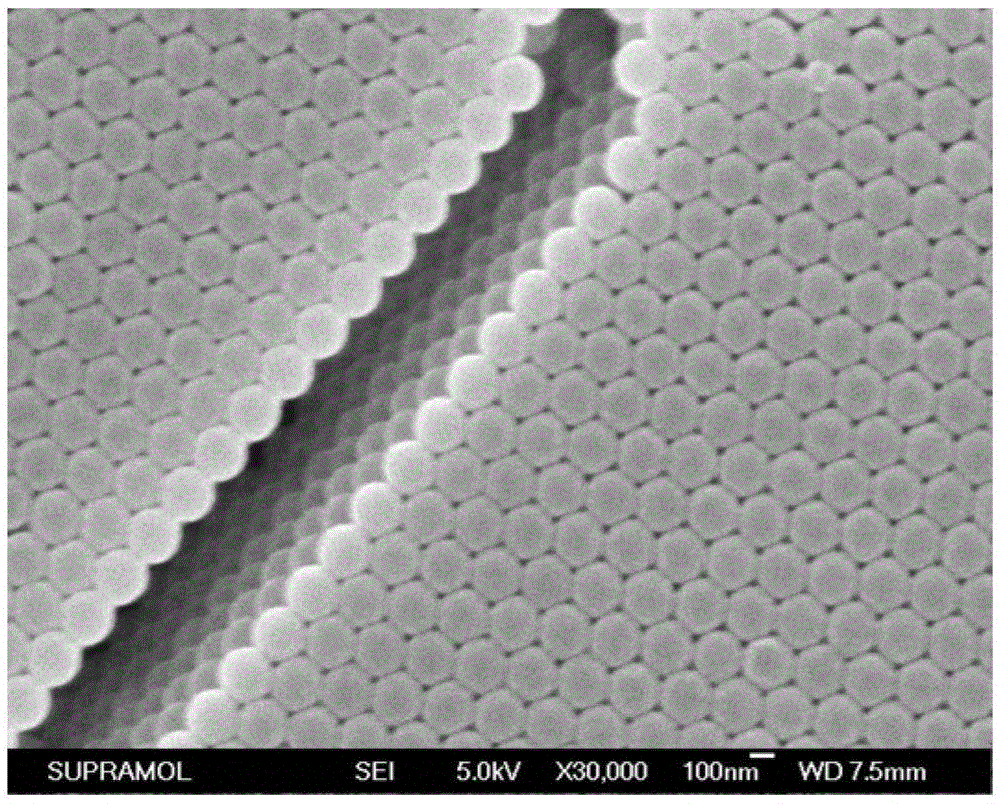

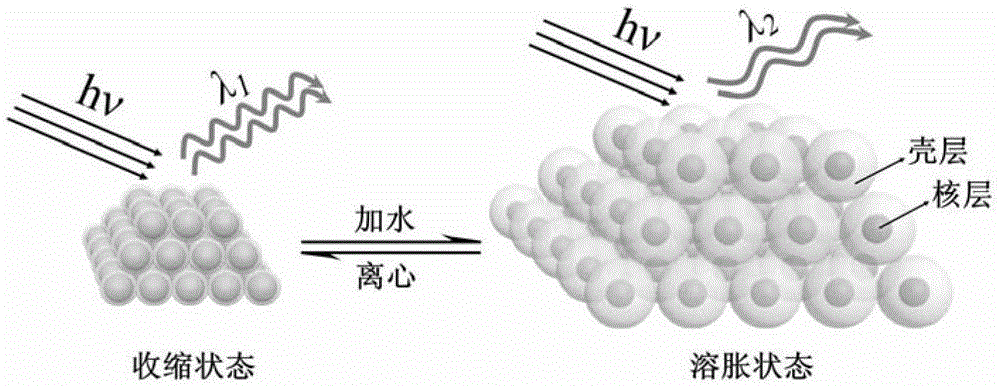

[0027] (1) Put N,N dimethylacrylamide (2mL), styrene (5mL), emulsifier (SDS, 0.05g) and deionized water (150mL) into a reaction vessel by emulsion polymerization, and put The reactor was placed in a water bath, first mechanically stirred (400r / min) at room temperature and nitrogen was blown for 30 minutes to make the micelles in the system evenly distributed. Then the temperature was raised to 70°C, and an initiator (KPS, 0.30 g) was added to react for 8 hours to obtain monodisperse hydrogel polymer microspheres with a particle size of 180 nm. The reaction product was centrifuged and washed 3 times with deionized water to remove unreacted monomer and initiator.

[0028] (2) The hydrogel polymer microspheres with uniform size obtained in step (1) were assembled into polymer photonic crystals by centrifugal deposition (through a high-speed centrifuge, centrifugal deposition at a speed of 80,000r / min for 30min) (PCCs, three-dimensional hexagonal close-packed structure, mass m ≥ ...

Embodiment 2

[0031] (1) Through emulsion polymerization, put N isopropylacrylamide (5mL), α-methylstyrene (5mL), emulsifier (SDBS, 0.05g) and deionized water (300mL) into a reaction vessel , put the reactor in a water bath, first mechanically stir (400r / min) at room temperature and blow nitrogen for 30 minutes, so that the micelles in the system are evenly distributed. The temperature was raised to 70° C., and then an initiator (KPS, 0.45 g) was added to react for 8 hours. Monodisperse hydrogel polymer microspheres with a particle size of 150 nm were obtained, and the reaction product was centrifuged and washed 3 times with deionized water to remove unreacted monomers and initiators.

[0032] (2) The hydrogel polymer microspheres with uniform size obtained in step (1) are assembled into polymer photonic crystals by means of centrifugal deposition (through a high-speed centrifuge, centrifugal deposition at a speed of 100,000r / min for 30min) (PCCs, three-dimensional hexagonal close-packed s...

Embodiment 3

[0035] (1) Put glycidyl methacrylate (2mL), divinylbenzene (5mL) and deionized water (150mL) into a reaction vessel (SDS, 0.0g) by means of emulsion polymerization. Place the device in a water bath, first mechanically stir (400r / min) at room temperature and blow nitrogen for 30 minutes, so that the micelles in the system are evenly distributed. Afterwards, the temperature was raised to 70° C., and then an initiator (SPS, 0.30 g) was added to react for 8 hours. Monodisperse hydrogel polymer microspheres with a particle size of 200 nm were obtained, and the reaction product was centrifuged and washed 3 times with deionized water to remove unreacted monomers and initiators.

[0036] (2) The hydrogel polymer microspheres with uniform size obtained in step (1) are assembled into polymer photonic crystals by means of centrifugal deposition (through a high-speed centrifuge, centrifugal deposition at a speed of 50,000r / min for 60min) (PCCs, three-dimensional hexagonal close-packed st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com